Plastic bottle cap screening device

A screening device and bottle cap technology, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of no correction, low screening efficiency, difficult normal screening, etc., to eliminate mutual influence and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

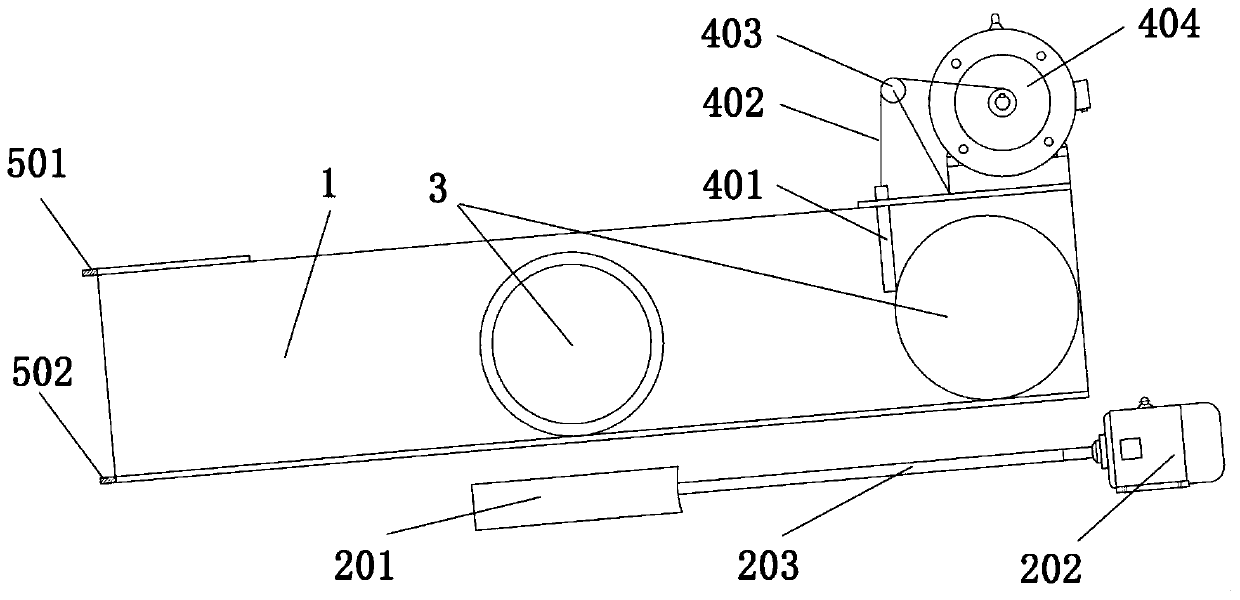

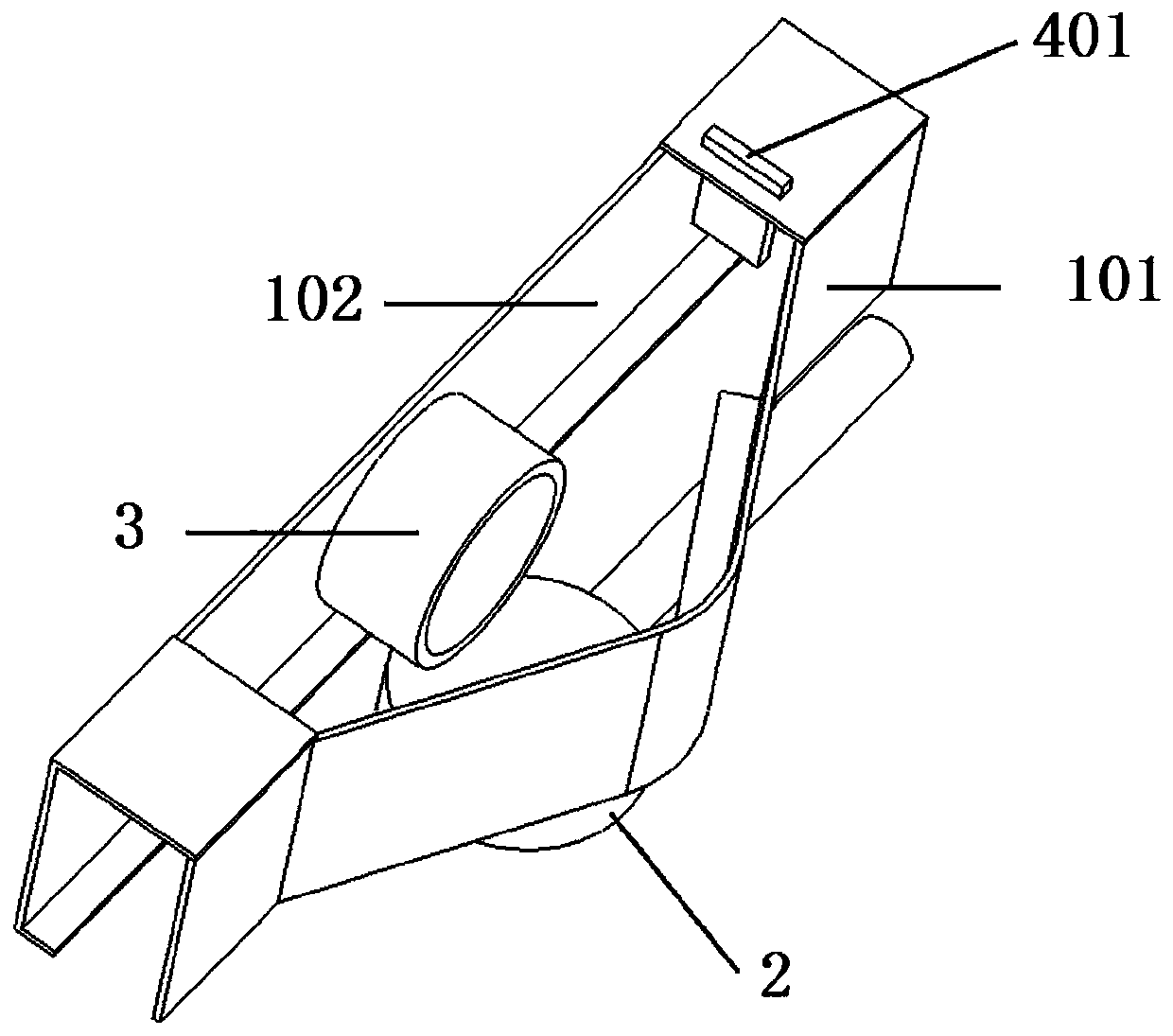

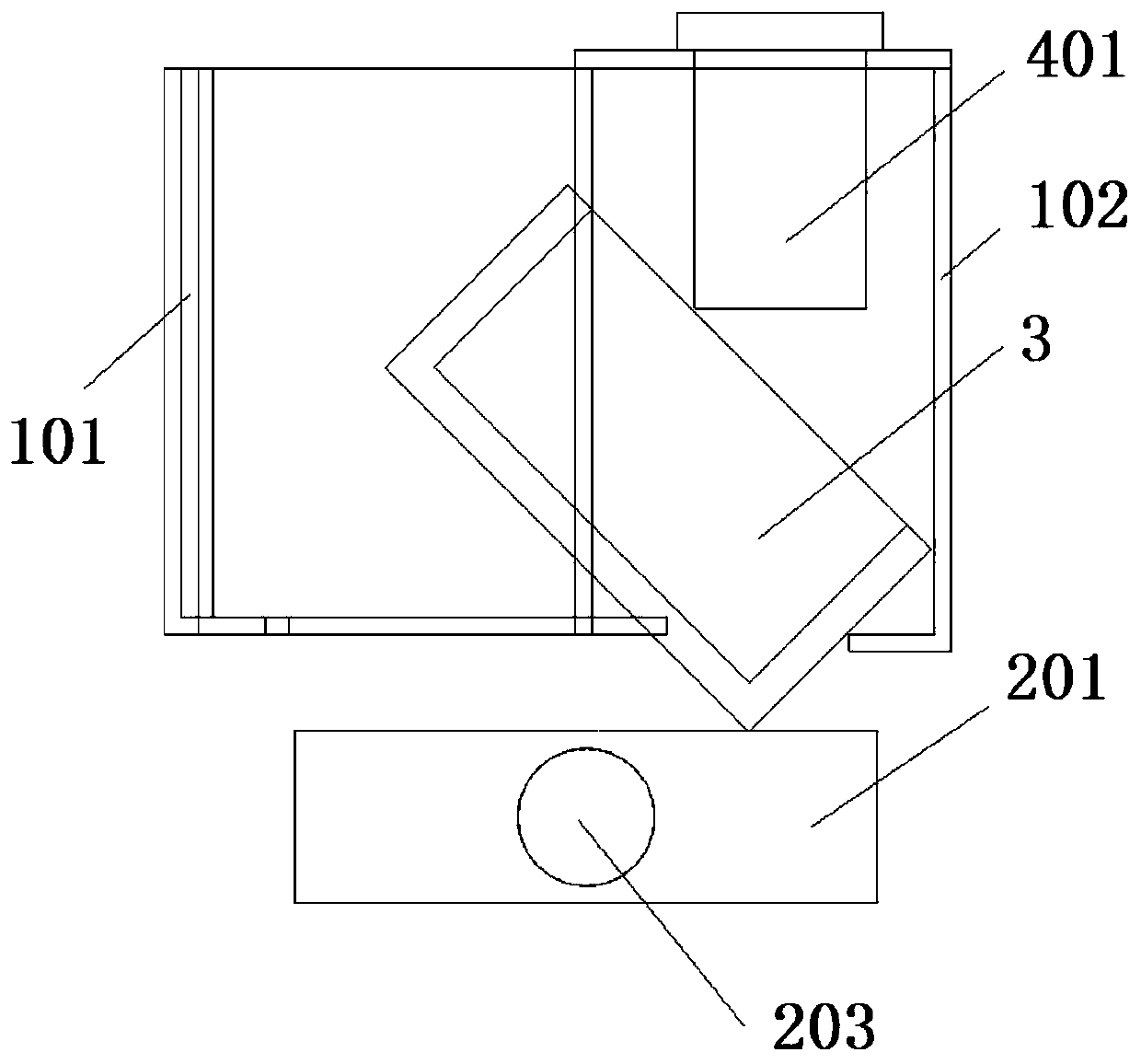

[0020] refer to Figure 1 to Figure 6 A screening device for plastic bottle caps shown includes a raceway 1 and an overturning device 2. The raceway 1 is inclined and is used for the inside of the bottle cap 3 when it stands up. The bottle cap 3 can roll under the action of gravity. The overturning device 2 is located directly below the gap at the bottom of the raceway 1, and is used to turn over the bottle cap 3 back to the raceway when a bottle cap 3 falls from the gap of the raceway 1.

[0021] The raceway 1 comprises a raceway front wall 101 and a raceway rear wall 102. The raceway front wall 101 and the raceway rear wall 102 are made of thin-walled smooth materials, which facilitate the sliding of the bottle cap 3 on its surface. The raceway front wall 101. The rear wall 102 of the raceway is connected by weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com