Tableware packing machine

A packaging machine and tableware technology, applied in packaging machines, packaging, transportation packaging and other directions, can solve the problems of low packaging efficiency, uneven packaging quality, time-consuming and labor-intensive, and achieve high packaging efficiency, good packaging quality, and time saving. Labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing:

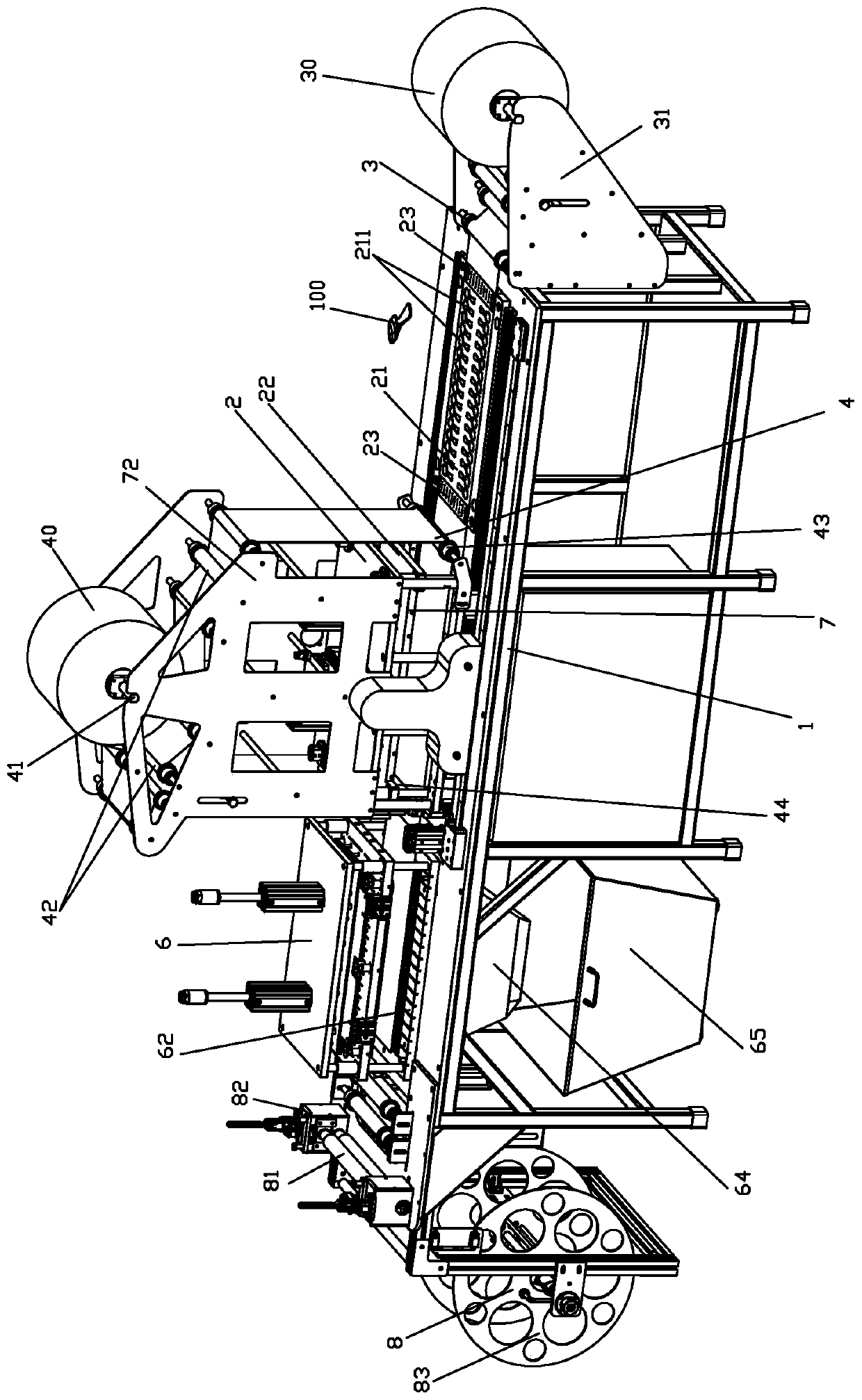

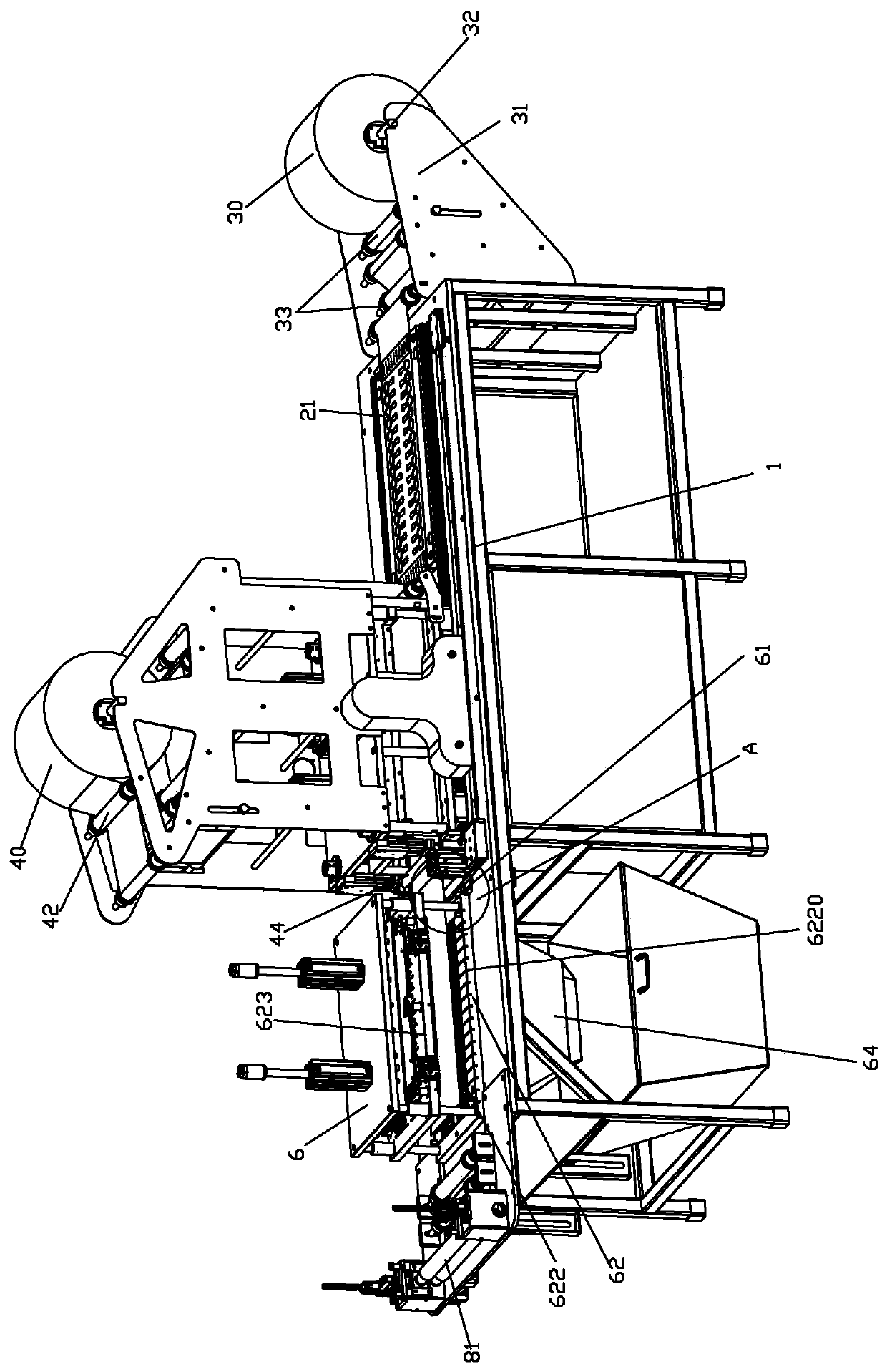

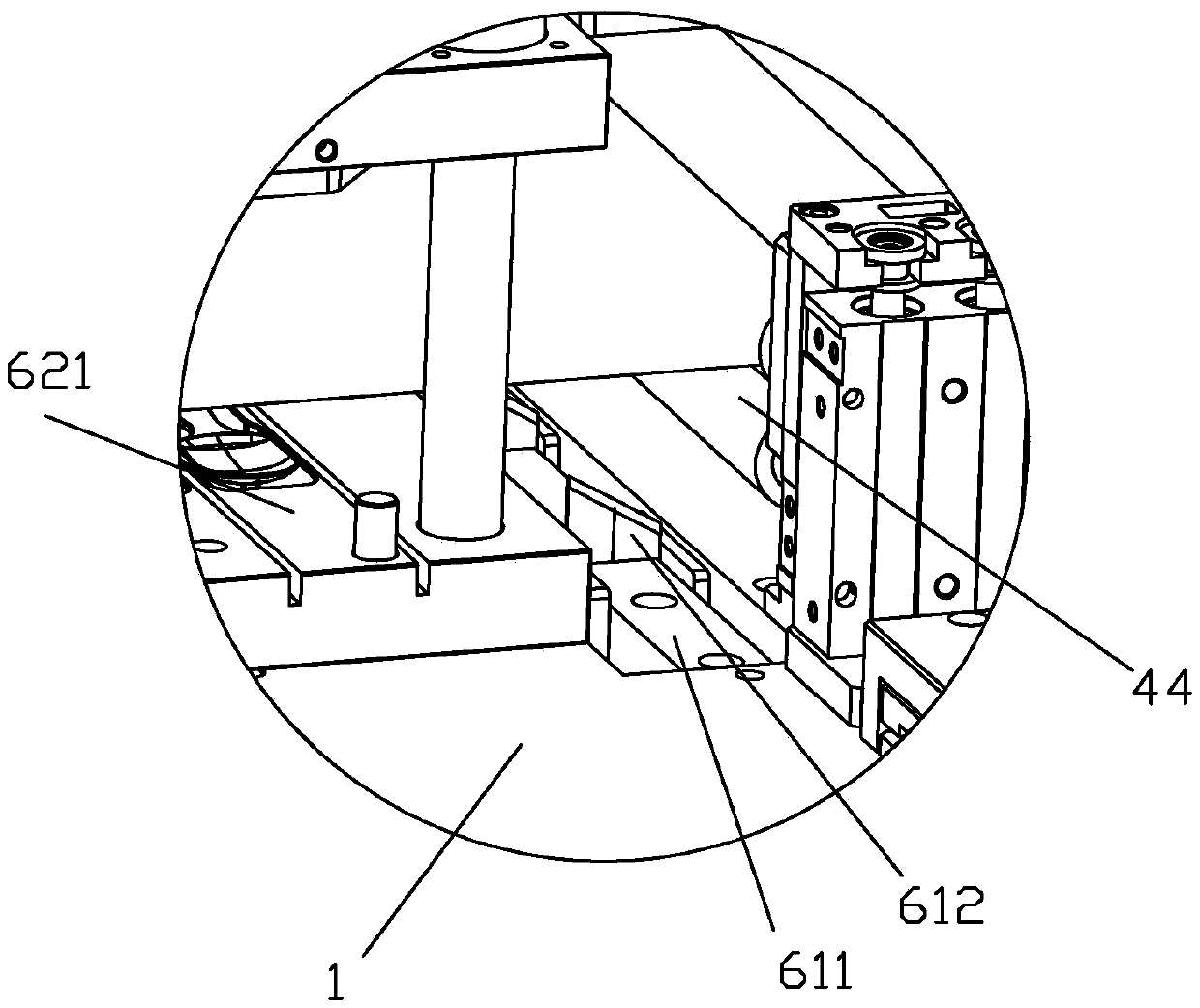

[0035] A tableware packaging machine, which includes a frame 1; and a packaging mechanism 2 for sealing and packaging tableware 100; the packaging mechanism 2 includes a bottom plate 21 and a heat-sealing plate 22, and can make the bottom plate 21 and the heat-sealing plate 22 close together for heat-sealing packaging The mobile device, the bottom plate 21 is provided with multiple and multi-row tableware lower accommodating chambers 211 in each row; and the upper film assembly 4 that can transport the upper film 40 and cover the upper film 40 on the bottom plate 21 of the tableware 100; and the cutting mechanism 6, the cutting mechanism 6 includes a plurality of tableware packages that can be sealed and packaged Cut into a vertical knife device 61 and a horizontal knife device 62 for individual packaged tableware. The present invention first sticks a layer of base film 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com