Railway piggyback transport vehicle and chassis thereof

A transport vehicle and piggyback technology, which is applied in the field of transportation, can solve the problems of road vehicle height restrictions and low loading and unloading efficiency, and achieve the effects of reducing the loading center of gravity, simplifying loading, and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to more clearly illustrate the technical solutions of the embodiments of the present application, the accompanying drawings used in the embodiments will be briefly introduced below. It should be understood that the following drawings only show some embodiments of the present invention, and therefore are not It should be regarded as a limitation on the scope, and those skilled in the art can also obtain other related drawings based on these drawings without creative work.

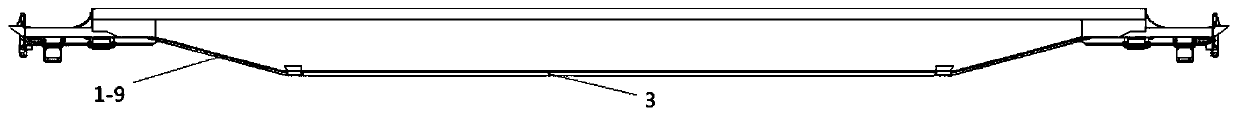

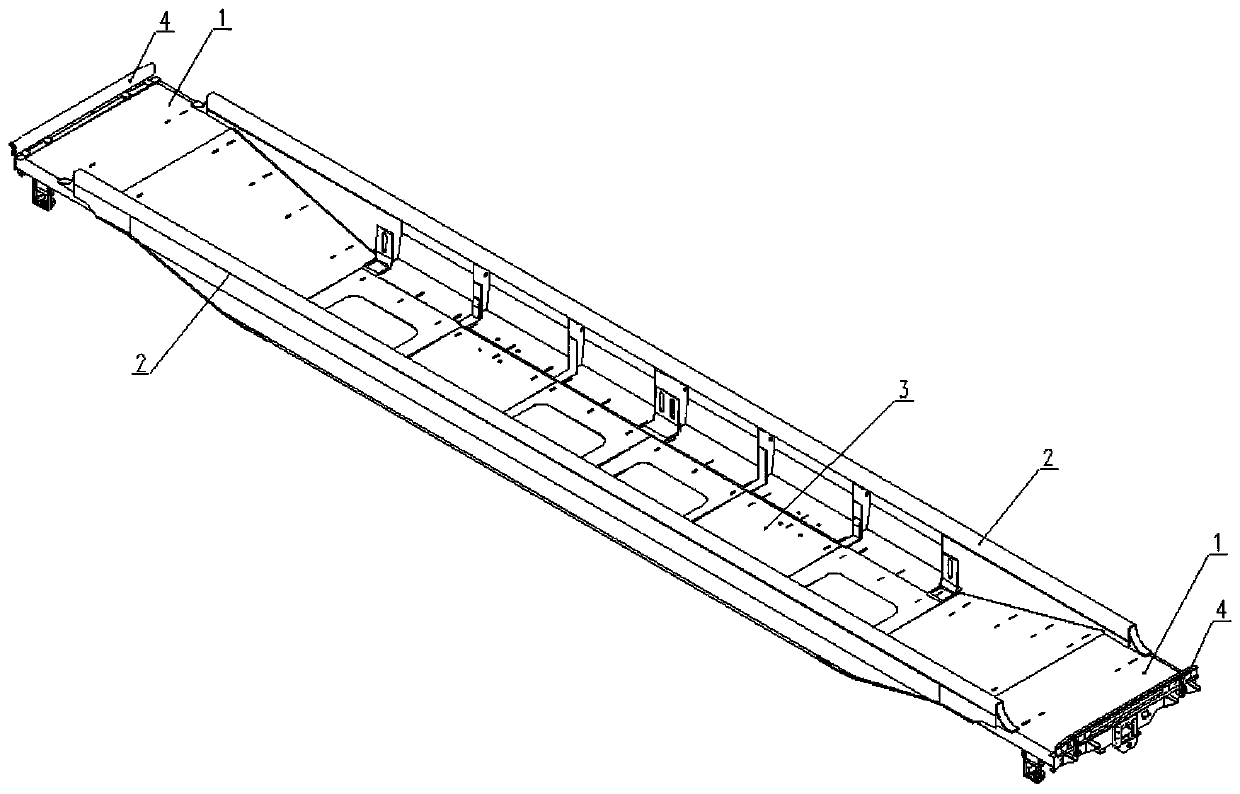

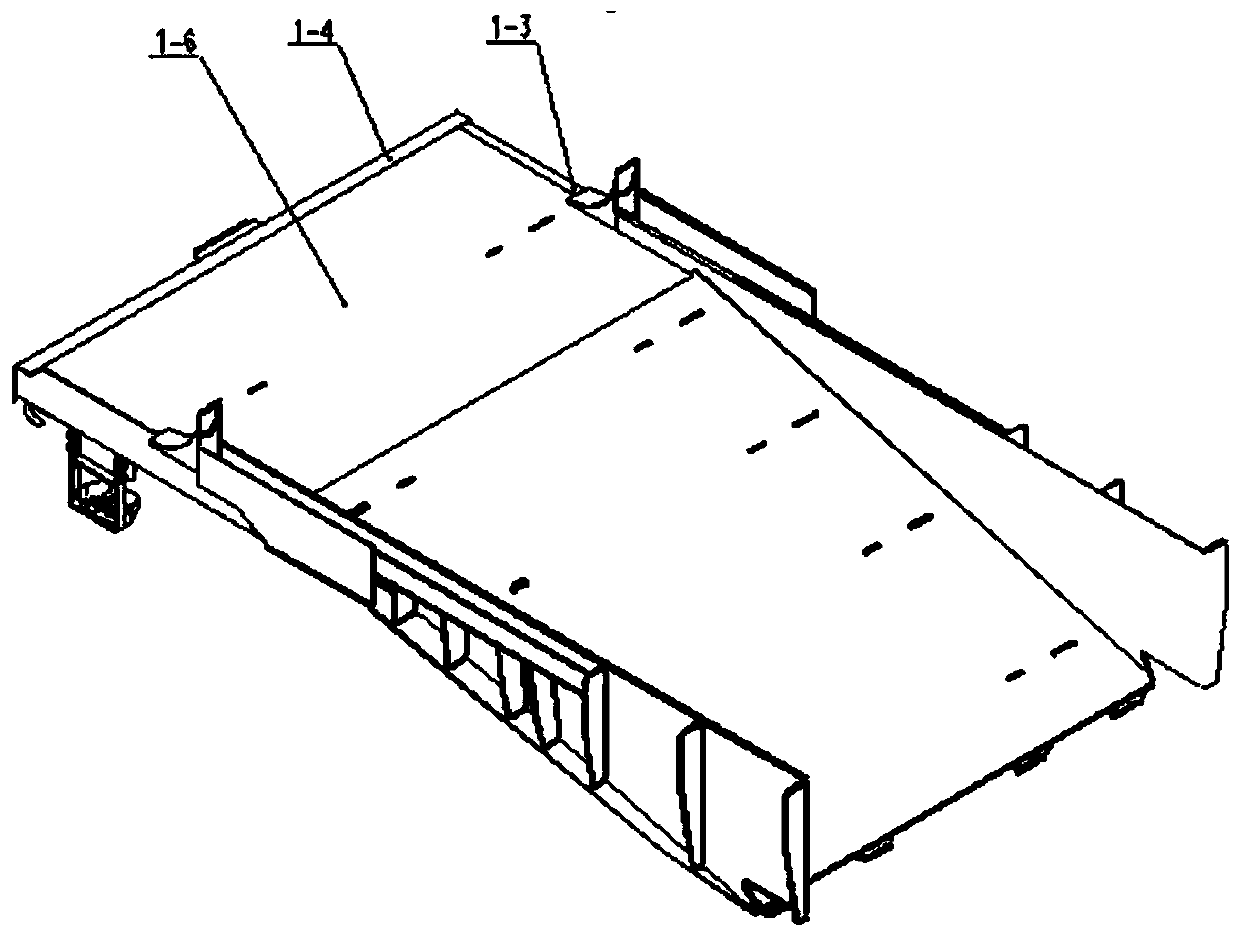

[0062] Such as Figure 1-14 As shown, an underframe 100 of a railway piggyback transport vehicle is characterized in that it comprises: a middle frame structure 3 and two end frame structures 1; The structures 1 are connected, and the middle frame structure 3 extends horizontally; the level of the middle frame structure 3 is lower than the level of the two end frame structures 1; the end frame structure 1 includes a first floor 1-6 and a sloping plate 1-9, the first floor 1-6 extends along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com