Equipment for processing furniture panels

A board processing and furniture technology, applied in the field of furniture manufacturing, can solve the problems of affecting the processing efficiency of furniture boards, inaccurate positioning of connection holes, and low positioning accuracy, and achieve the effects of improving processing and positioning efficiency, improving work efficiency, and improving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

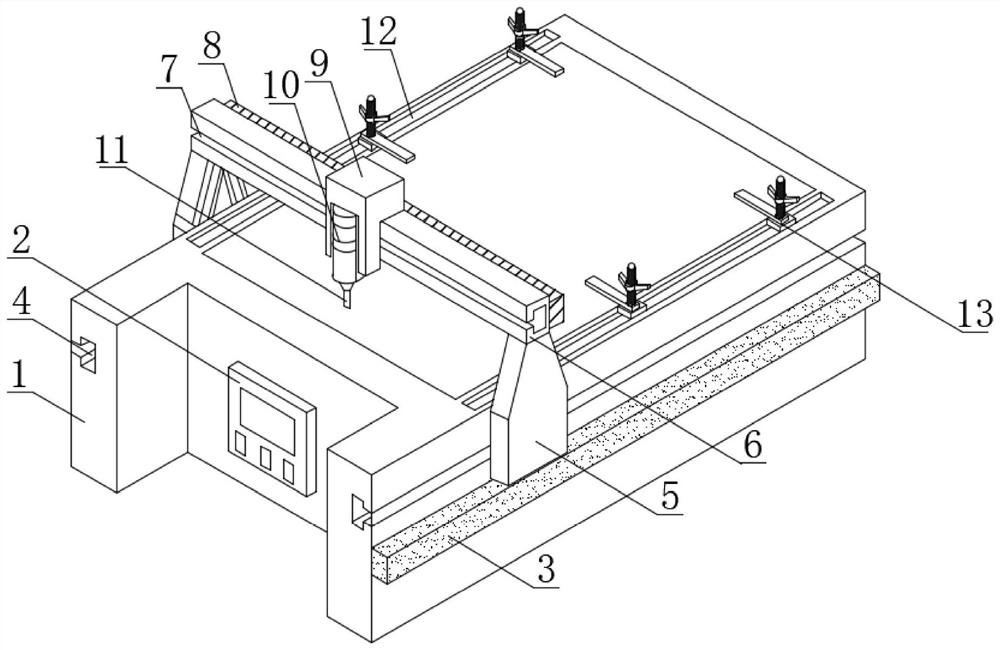

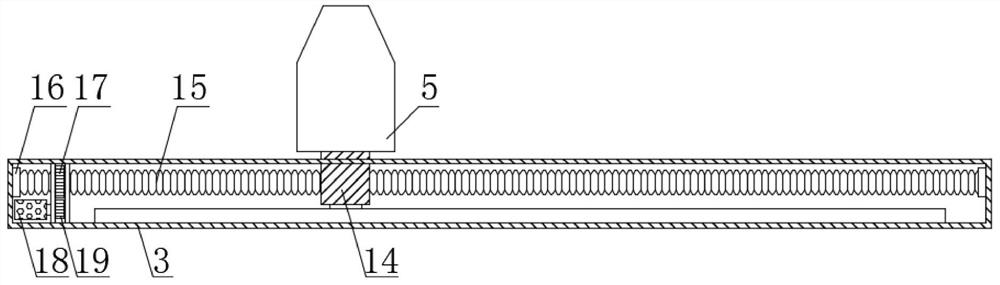

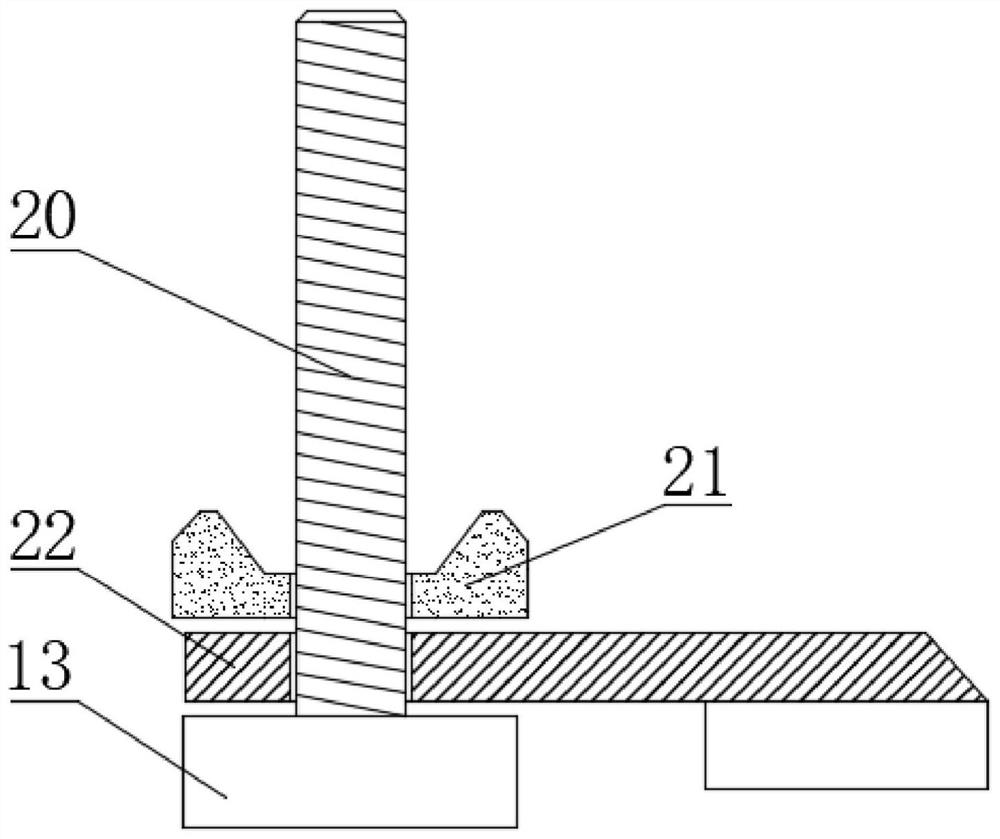

[0027] refer to Figure 1-5 , a kind of equipment for processing furniture boards, comprising a machine base 1, a two-dimensional moving mechanism, a processing head mechanism, a locking mechanism, and a board moving mechanism, wherein, two-dimensionally movable is provided on the said machine base 1 mechanism, the processing head mechanism is set on the two-dimensional moving mechanism, the locking mechanism is set on the upper end of the machine base, and the upper end of the machine base is also provided with a The plate moving mechanism is characterized in that,

[0028] The plate moving mechanism includes a belt coarse moving mechanism and a fine-tuning and fine-moving mechanism, wherein both the belt coarse-moving mechanism and the fine-tuning and fine-moving mechanism can be independently controlled to lift, and the rough-moving mechanism and the fine-tuning and fine-moving mechanism are lifted The plate 33 can be transported, and the plate 33 can be supported against ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com