Use method of reinforcement cage seam welder

A technology of steel cage and seam welding machine, which is applied in the direction of roller electrode welding, welding equipment, welding equipment, etc., can solve the problem of low efficiency of steel cage production, and achieve the effect of improving construction efficiency, reducing labor intensity and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

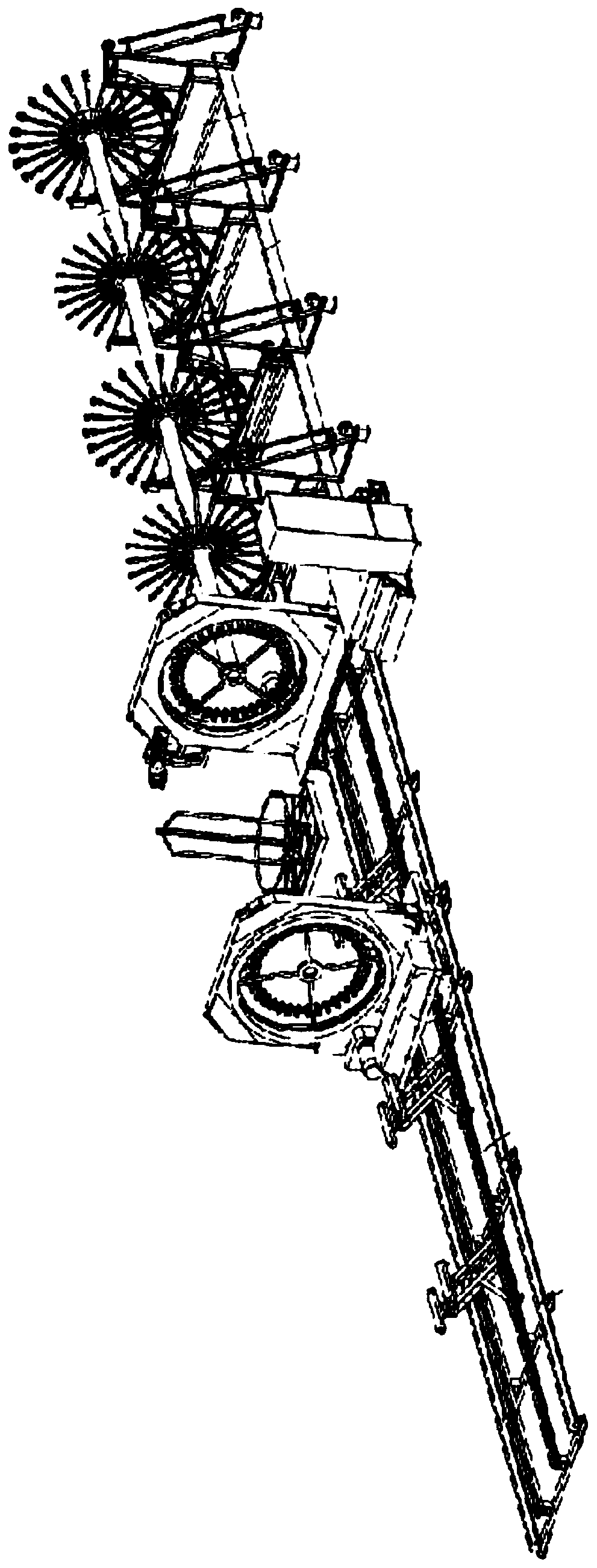

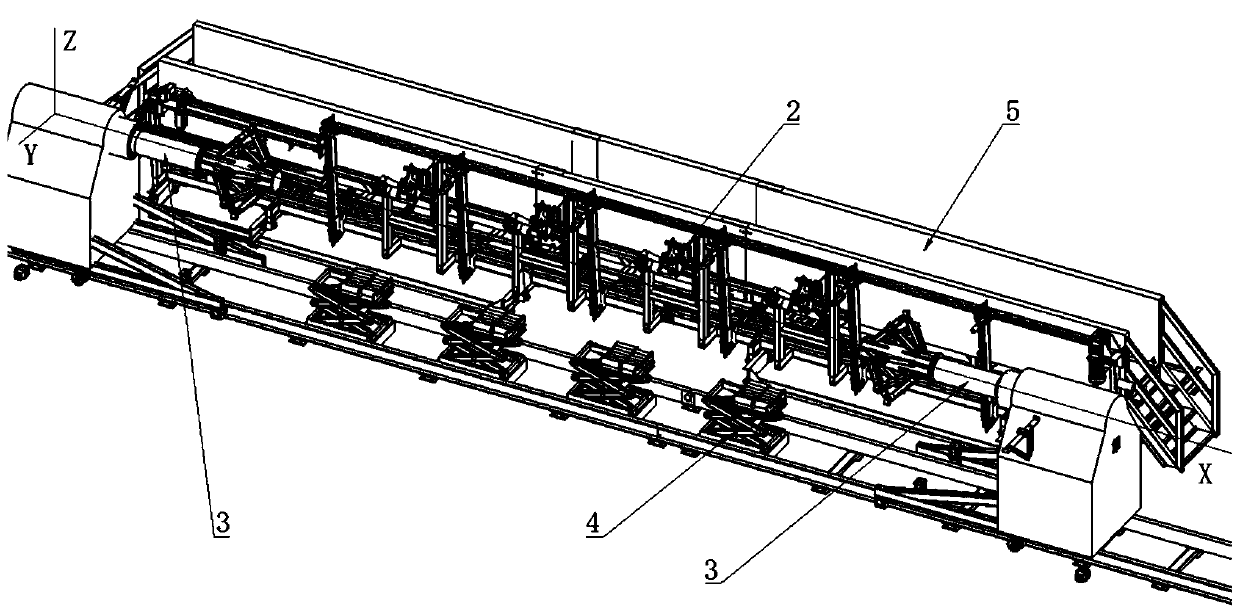

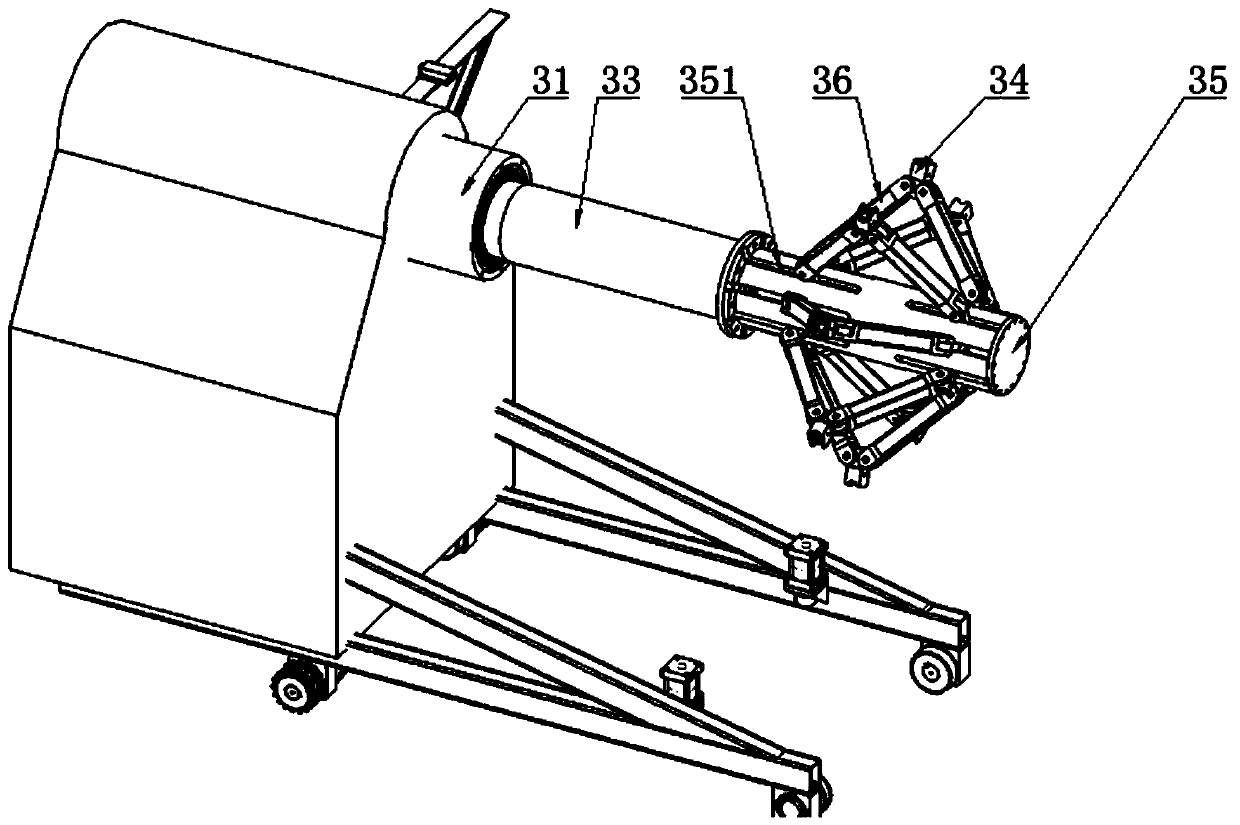

[0098] A steel cage seam welding machine, which fixes and supports the inner bracing ribs, then welds the main ribs to the inner brace ribs in turn, and then performs the main reinforcement and the winding reinforcement welding process. The steel cage seam welding machine includes: an inner brace supporting device, which is used for arranging and supporting a plurality of inner bracing ribs along the first straight line X; The several inner bracing ribs rotate synchronously around the first straight line X; the main rib feeding rack is arranged on one side of the inner bracing rib supporting device and is used to transport the main ribs to the outer side walls of the plurality of inner bracing ribs The mobile winding machine is arranged on either side of the inner brace supporting device, and the mobile winding machine can reciprocate along the fifth straight line; wherein, the first straight line X is parallel to the fifth straight line.

[0099] It is easy to understand that th...

Embodiment 2

[0188] In a specific embodiment, the working process is as follows:

[0189] The steel cage seam welding machine is set horizontally, that is, the first straight line X, the second straight line, and the third line Y are on the same horizontal plane, and the fourth straight line Z is on the plumb surface. On the ground is fixed on a walking track composed of two parallel I-beams, two mobile platforms are installed symmetrically on the walking track, the support frame 3 is correspondingly set on the mobile platform, and the walking track between the two support frames 3 A main rib upper material rack 5 is fixed on the ground on one side of the main rib, and on the front side of the main rib upper material rack 5, a plurality of inner brace clamping drives 2 are arranged horizontally along the first line X, between the two support frames 3 A number of hydraulic telescopic support frames 4 are also arranged on the walking track. The inner brace clamping drive 2 and the hydraulic te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com