Coiler drum and coiling method capable of preventing steel coil from collapsing

A steel coil and machine coil technology, applied in the field of metallurgical steel rolling machinery, can solve the problems of high coiling tension, increase user costs, reduce product yield and other problems, increase secondary expansion force, improve sheet utilization, and ensure normal running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

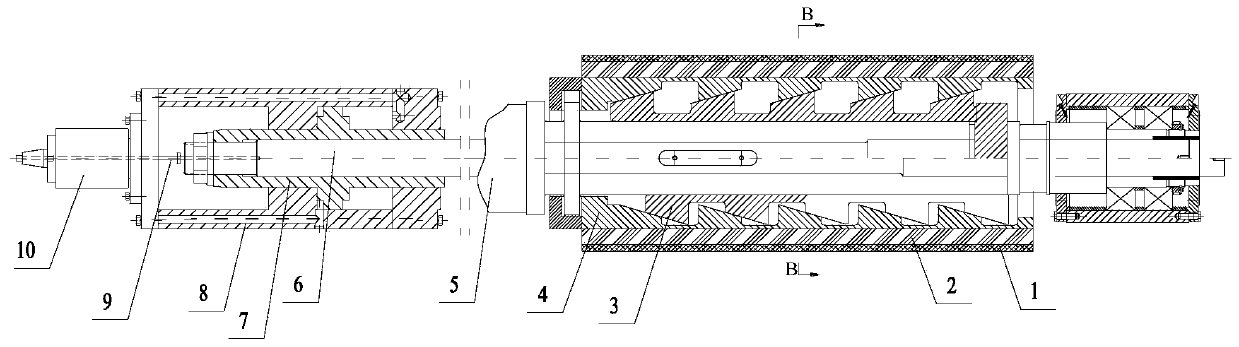

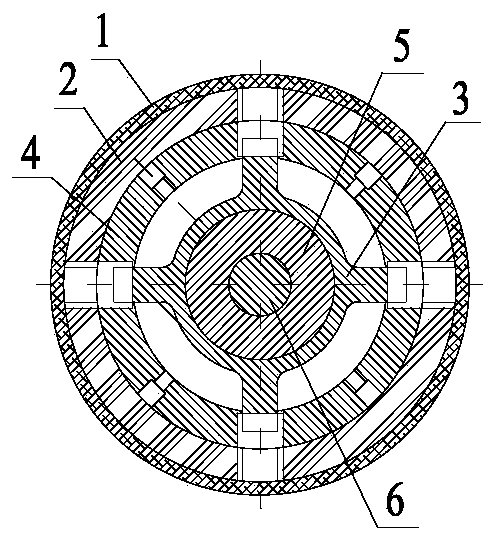

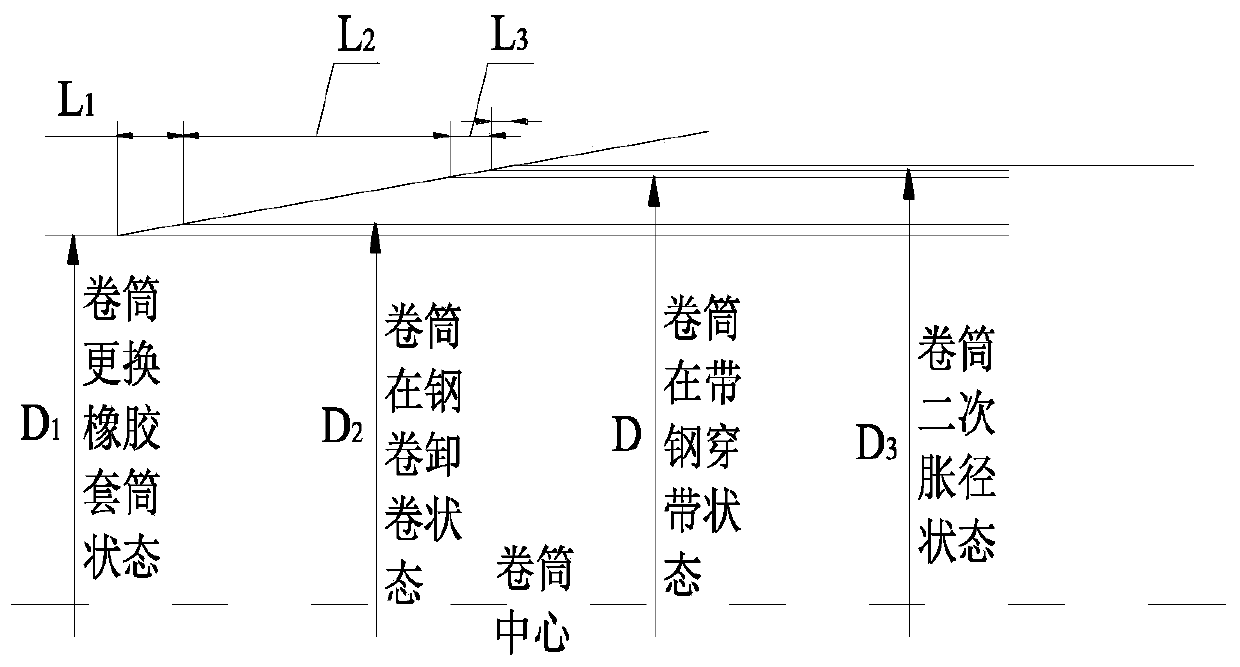

[0019] Such as figure 1 , figure 2 The coiler reel that can prevent the steel coil from collapsing shown in the figure includes a rubber sleeve 1, a plastic arc plate 2, a fan plate 4, a reel pyramid 3, a reel hollow main shaft 5, and an expander from the outside to the inside. The diameter cylinder 8, the rotary oiler 10 installed at one end of the expansion cylinder 8, the pull rod 6 fixedly connected to the piston 7 of the expansion cylinder 8 and connected to the piston 7 at one end, and the displacement sensor 9 installed at the end of the rotary oiler 10, The signal receiving end of the displacement sensor 9 passes through the rotary oiler 10 until the signal receiving end extends into the cavity of the pull rod 6. At the same time, the other end of the pull rod 6 is inserted into the reel hollow main shaft 5 and connected to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com