Heating non-combustion cigarette

A technology of heat-not-burn and cigarettes, which is applied in the fields of tobacco, cigar manufacturing, smoker’s supplies, etc. It can solve the problems of affecting the taste of heat-not-burn products, affecting production efficiency and product quality, and insufficient support of paper empty tubes. , to achieve the effect of improving the taste or smoke, improving production efficiency and product quality, and not easily deformed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

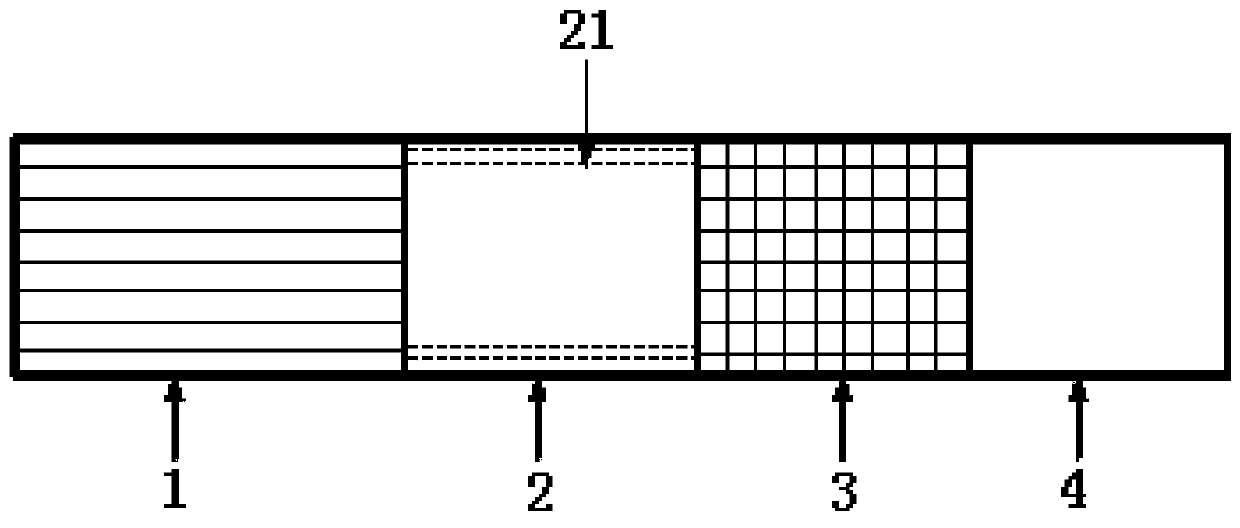

[0030] This embodiment is a heat-not-burn cigarette, which sequentially includes: an aerosol generating section 1 , a supporting element 2 , a cooling section 3 and a filter section 4 .

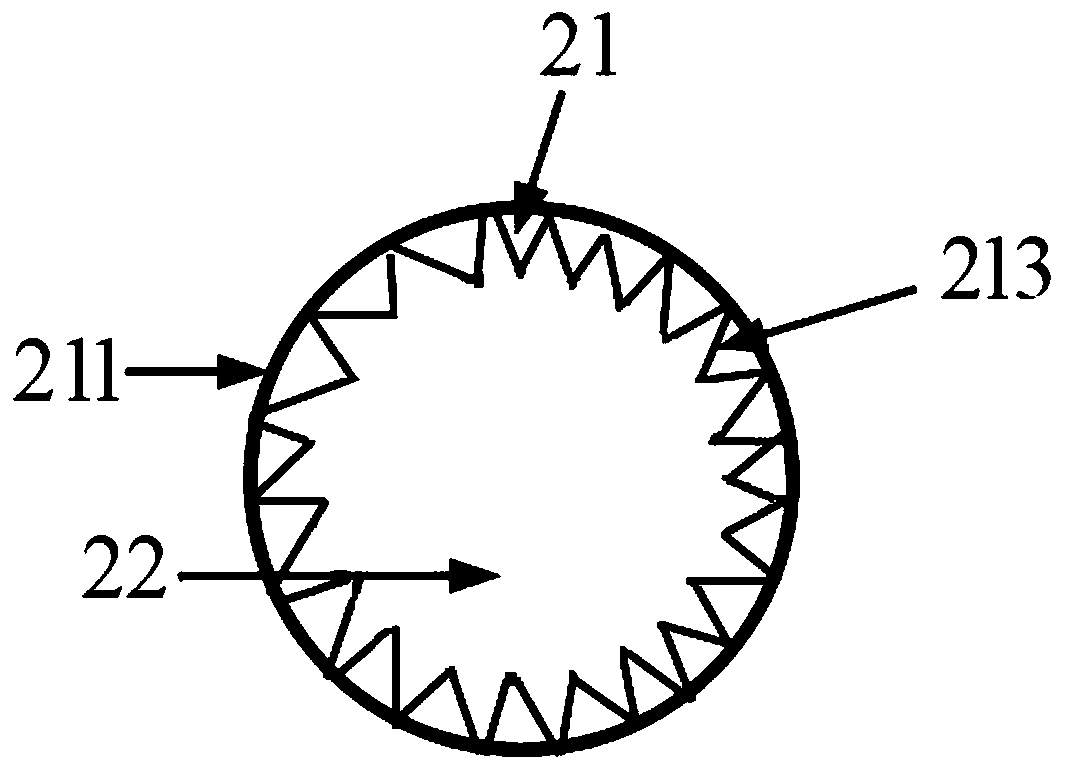

[0031] The support element 2 is an empty tube having a tube wall 21 and a lumen 22 , the tube wall 21 includes an outer wrapping layer 211 and a grooved corrugated layer 213 , and the grooved corrugated layer 213 is close to the lumen 22 .

[0032] The diameter of the lumen 22 is 4 mm, and the length of the support element is 10 mm.

[0033] The outer wrapping layer 211 is a molding paper of heat-not-burn cigarettes.

[0034] The grooved corrugated layer 213 is formed by rolling a sheet-shaped material selected from acetate fiber sheets, and the thickness of the sheet-shaped material is 0.1 mm.

[0035] The grooved corrugated layer 213 has a corrugated shape of an arc, and the thickness of the grooved corrugated layer 213 is 2 mm.

[0036] Wherein, the supporting element comprises a layer o...

Embodiment 2

[0044] This embodiment is a heat-not-burn cigarette, which sequentially includes: an aerosol generating section 1 , a supporting element 2 , a cooling section 3 and a filter section 4 .

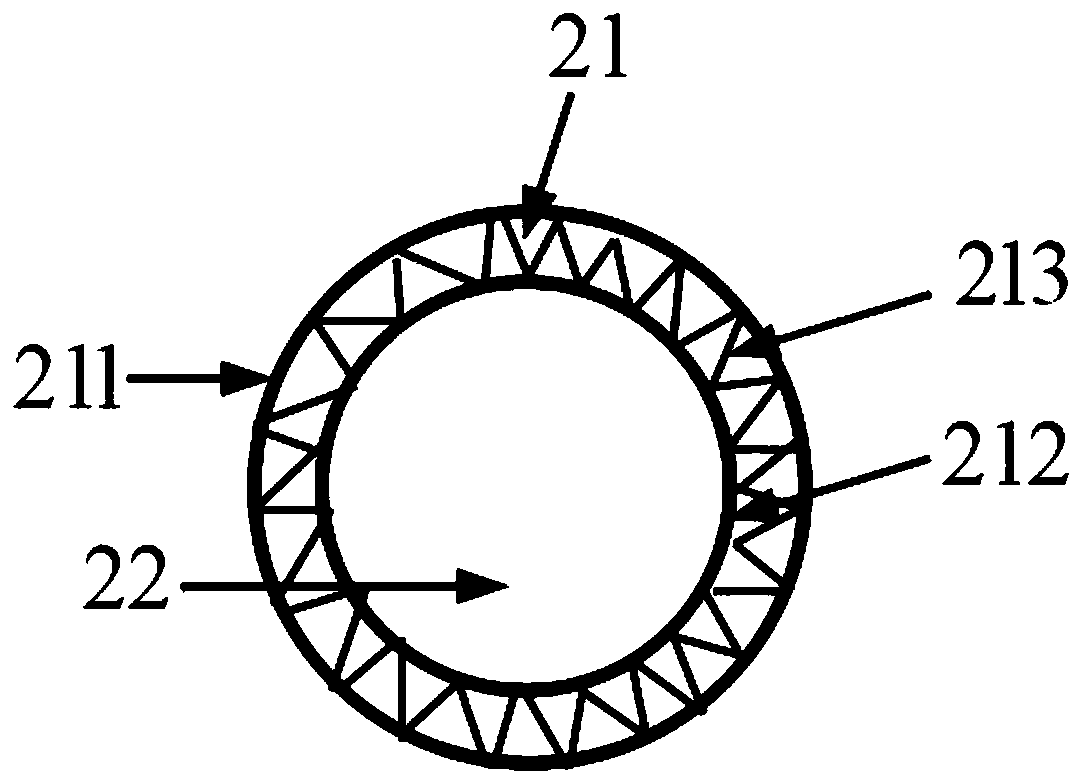

[0045] The support element 2 is an empty tube with a tube wall 21 and a lumen 22, the tube wall 21 includes an outer wrapping layer 211, an inner wrapping layer 212 and a grooved corrugated layer 213, and the grooved corrugated layer 213 is located on the between the inner wrapping layer 212 and the outer wrapping layer 211 .

[0046] The diameter of the lumen 22 is 1 mm, and the length of the support element is 10 mm.

[0047] The outer wrapping layer 211 is a molding paper of heat-not-burn cigarettes, and the inner wrapping layer 212 is an acetate fiber layer.

[0048] The grooved corrugated layer 213 is formed by rolling a sheet-shaped material selected from paper, and the thickness of the sheet-shaped material is 0.02mm-0.2mm.

[0049] The grooved corrugated layer 213 has a U-shaped cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com