Agricultural spreader for rice planting

An agricultural and rice technology, which is applied in the field of agricultural seeding vehicles, can solve the problems of feeding pipe blockage, damage to planter parts, and high labor costs, and achieve the effects of reducing load increase, prolonging service life, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

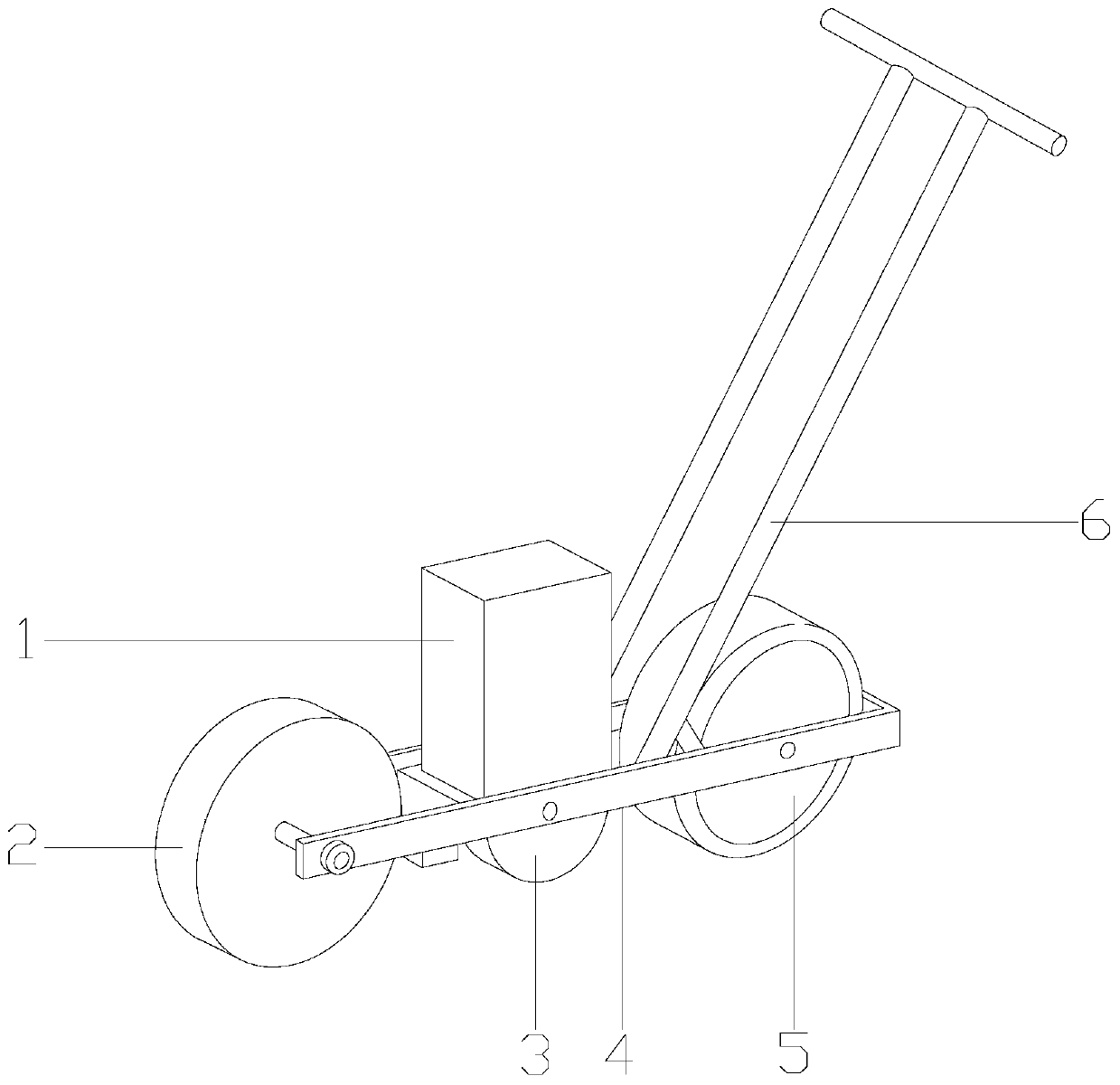

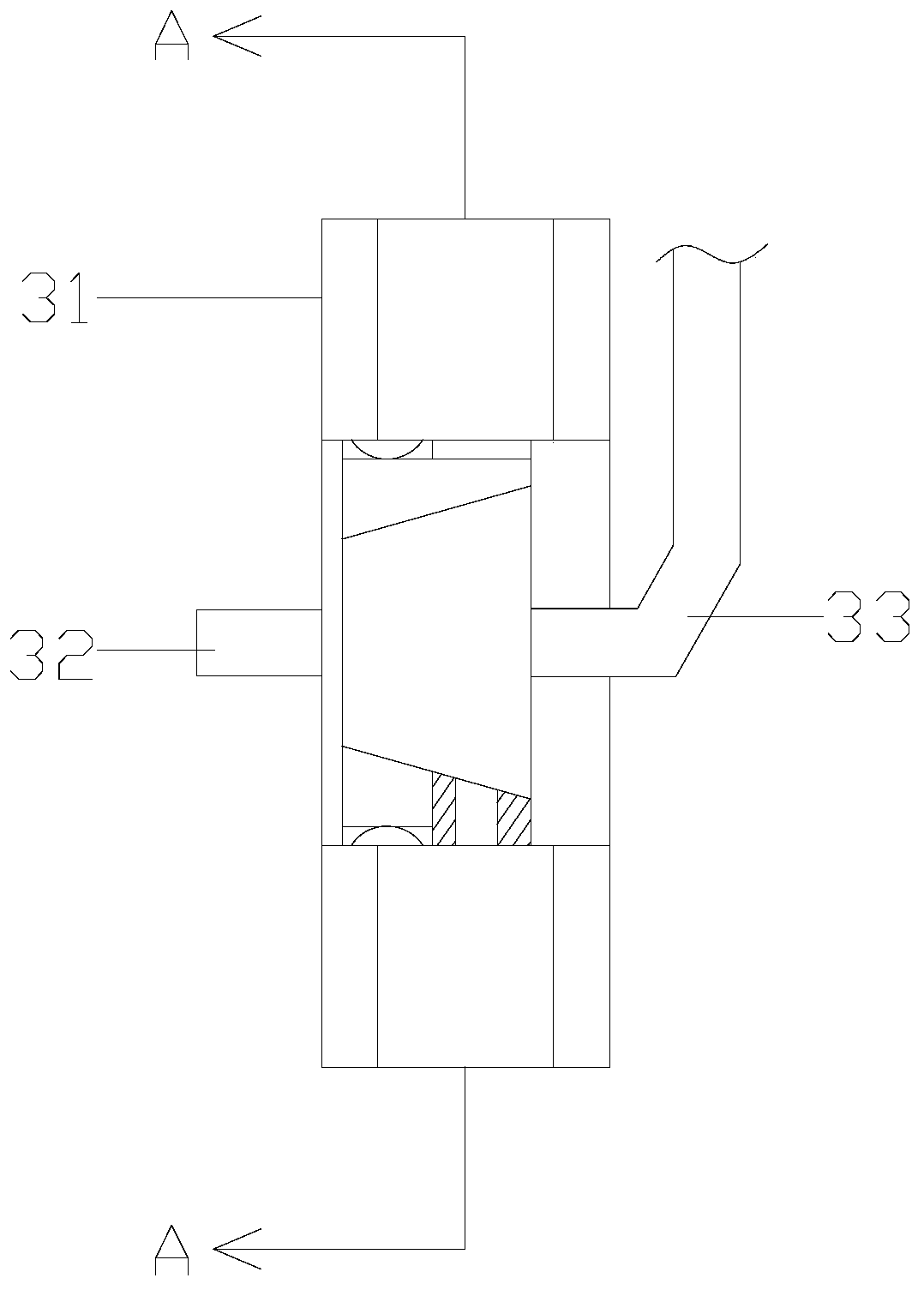

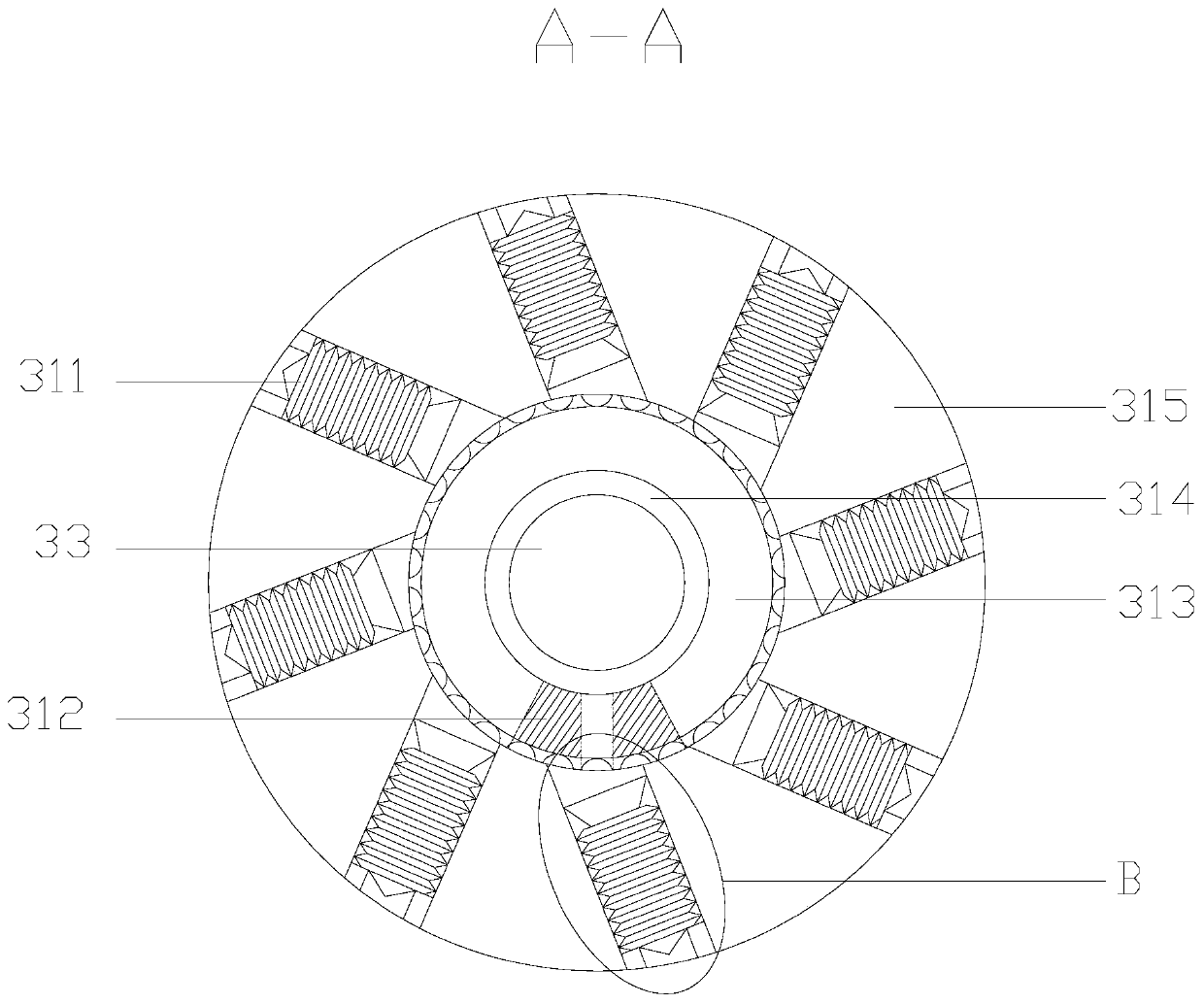

[0026] see Figure 1-Figure 2 , the present invention provides an agricultural seeding vehicle applied to rice planting, its structure includes a seed storage box 1, a traction wheel 2, a ditch feeding device 3, a connecting frame 4, a soil suppression wheel 5, a push handle 6, and the connecting frame 4 is a U-shaped structure and is parallel to the sowing ground. The middle of the front of the traction wheel 2 and the leftmost end of the connecting frame 4 are fixed together by bolts. The bottom of the seed storage box 1 and the middle of the connecting frame 4 are buckled together, the top of the ditching feeding device 3 is connected to the bottom of the sub-storage box 1, and the bottom of the push handle 6 is welded to the upper surface of the connecting frame 4 Together, the ditching feeding device 3 is composed of a ditching feeding wheel 31, a fixed shaft 32, and a seed feeding pipeline 33. The ditching feeding wheel 31 is located below the seed storage box 1, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com