Automatic conveying line for molded winding inductor processing

A technology of automatic conveying and inductors, which is applied in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc., can solve the problems of high degree of work automation, low work efficiency, and high output output, and achieve high work automation and work efficiency. The effect of high output and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

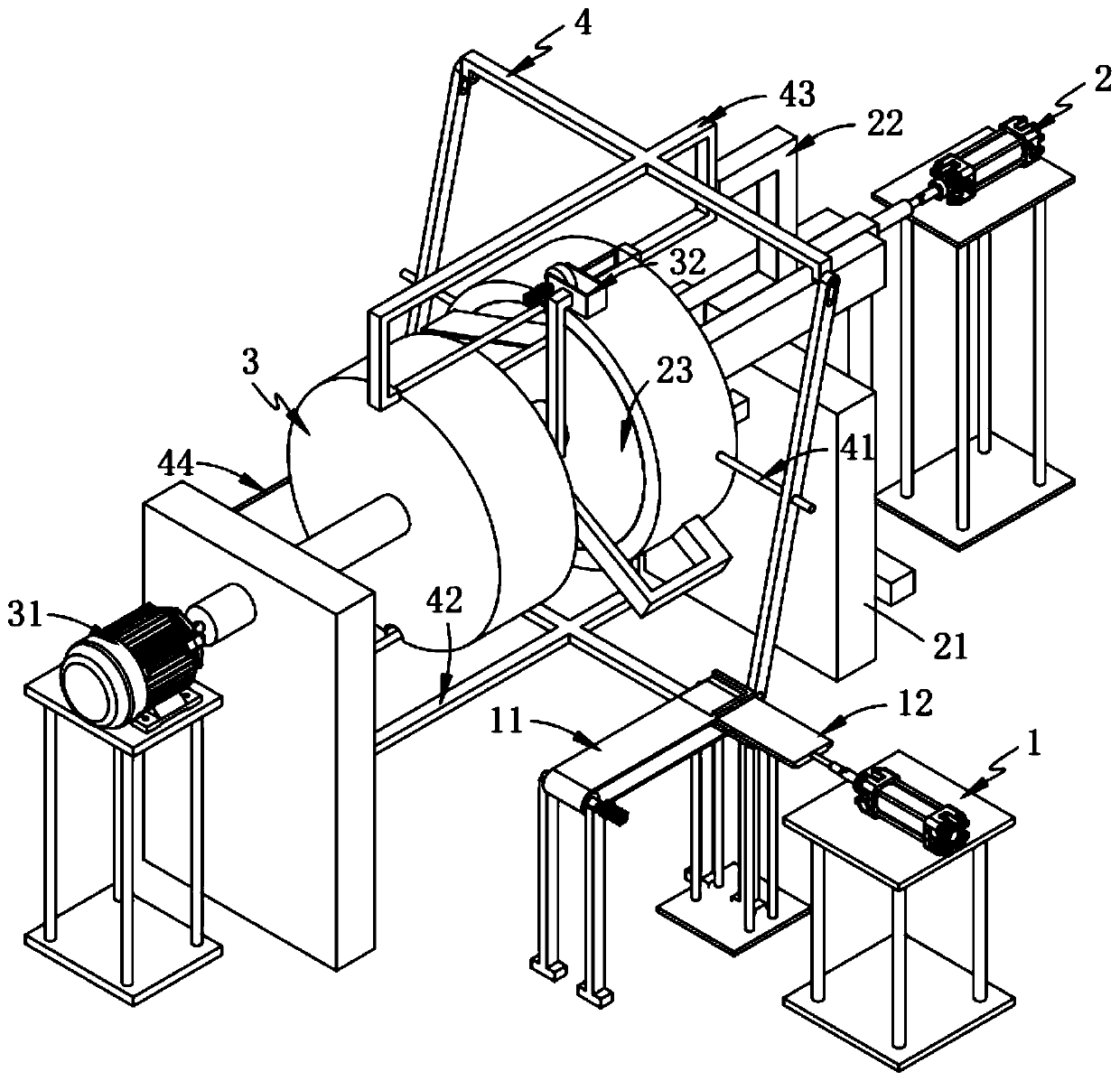

[0069] Such as figure 1 , Figure 8 with Figure 9 As shown, an automatic conveying line for processing molded wire wound inductors, including:

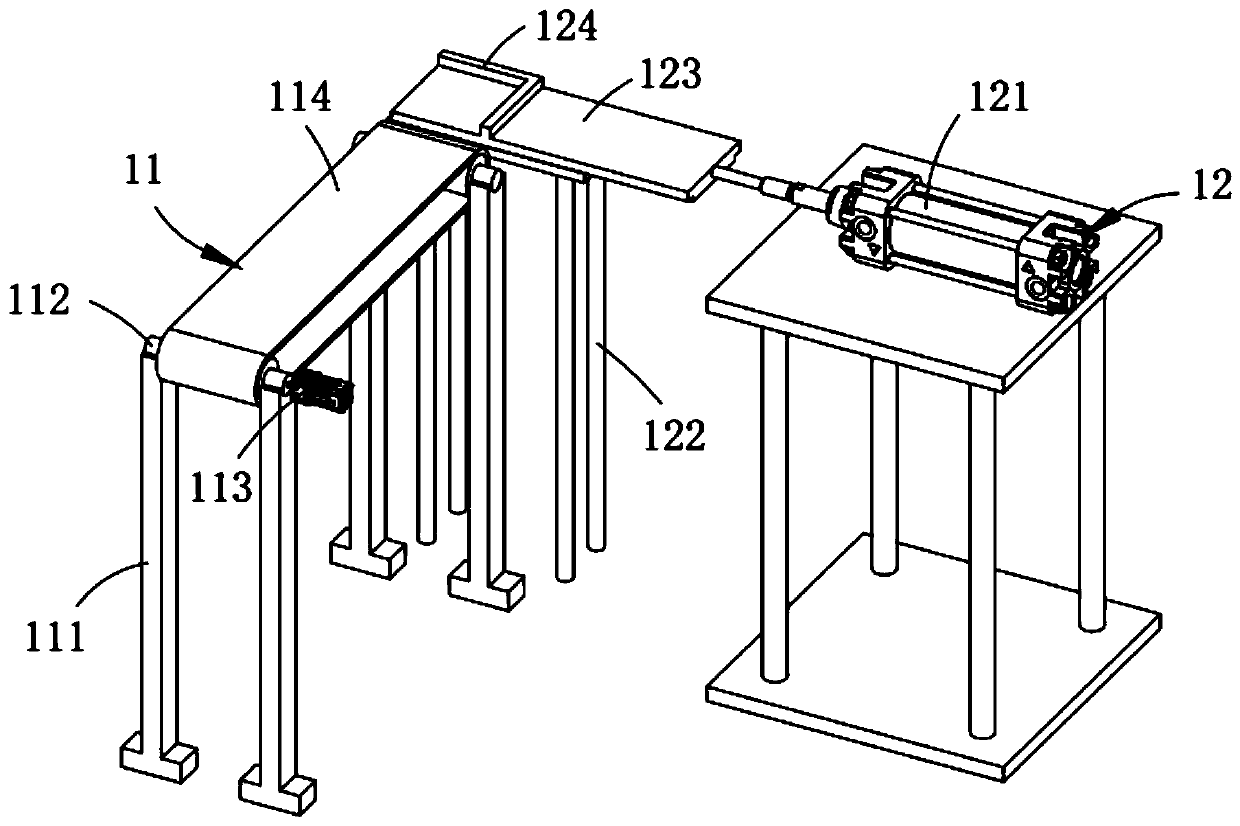

[0070] The first feeding mechanism 1, the first feeding mechanism 1 includes a transmission assembly 11 and a pneumatic assembly a12 arranged at the output end of the transmission assembly 11 and perpendicular to the transmission assembly 11;

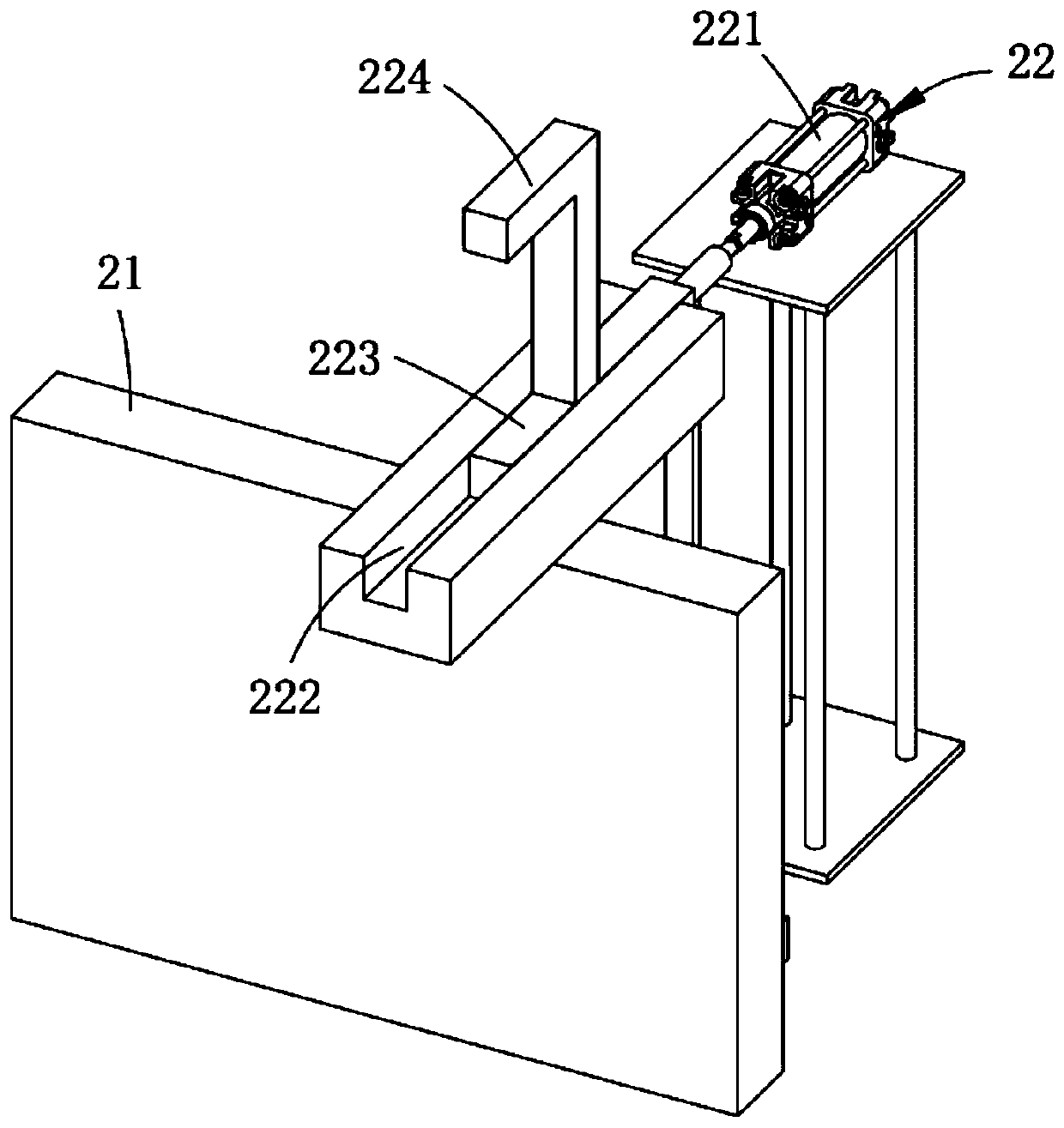

[0071] The second feeding mechanism 2, the second feeding mechanism 2 includes a frame 21 arranged in the direction of the output end of the pneumatic assembly a12, a pneumatic assembly b22 slidably arranged on the frame 21 and fixedly arranged on the The storage assembly 23 at the output end of the pneumatic assembly b22;

[0072] Circulation mechanism 3, said circulation mechanism 3 includes a revolving assembly 31 rotatably arranged on said storage assembly 23 and a gluing assembly 32 fixedly arranged on said storage assembly 23 and located above said revolving assembly 31; and

[0073]...

Embodiment 2

[0129] Such as Figure 4 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0130] further, such as Figure 4 As shown, the bottom diameter of the storage tank 233 is L1, the internal diameter of the positioning groove b318 is L2, the external diameter of the positioning groove b318 is L3, and the L1=L2>L3.

[0131] In addition, by setting L1=L2>L3, the magnetic core can pass directly from the material storage tank 233 into the positioning groove b318, but it is limited by the bottom of the positioning groove b318, so that when the magnetic core turns from the bottom 180°, it will not be caused by The fall occurs due to eccentric force, which ensures the stability of the work and has the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com