Thick wire fault distance-measuring and anti-wind shaking device

A fault location and wire technology, which is applied in the field of wires, can solve the problems that affect the results of fault location, the wire is easy to shake, and the stability of the connector is affected, so as to prevent instability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] as attached figure 1 To attach Figure 7 Shown:

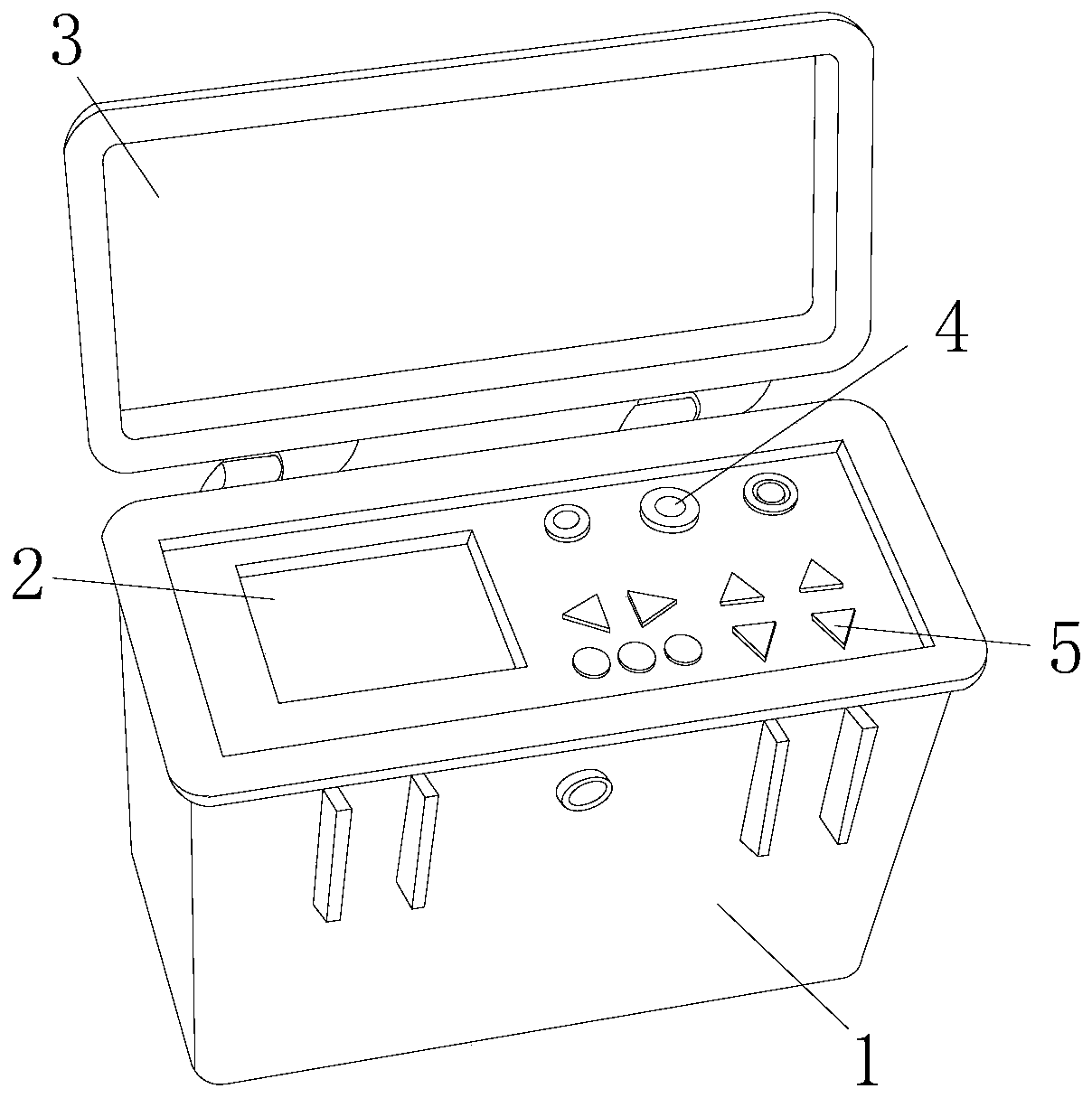

[0029] The invention provides a thick wire fault ranging and anti-wind swaying device, the structure of which includes a fault ranging box 1, a display screen 2, a protective cover 3, a thick wire wear-resistant interface 4, and an operation button 5.

[0030] The top of the fault distance measuring box 1 is equipped with an operation button 5 with a clearance fit, the display screen 2 and the operation button 5 are located on the same plane, the protective cover 3 is hinged with the fault distance measuring box 1 through a rotating shaft, and the rough The anti-wear interface 4 is located at the top of the fault distance measuring box 1 .

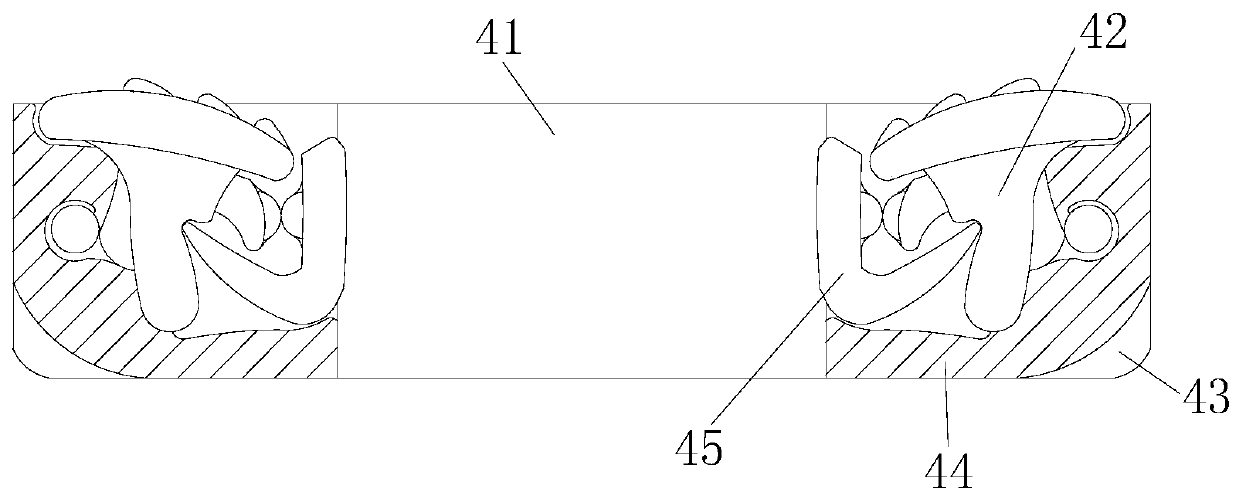

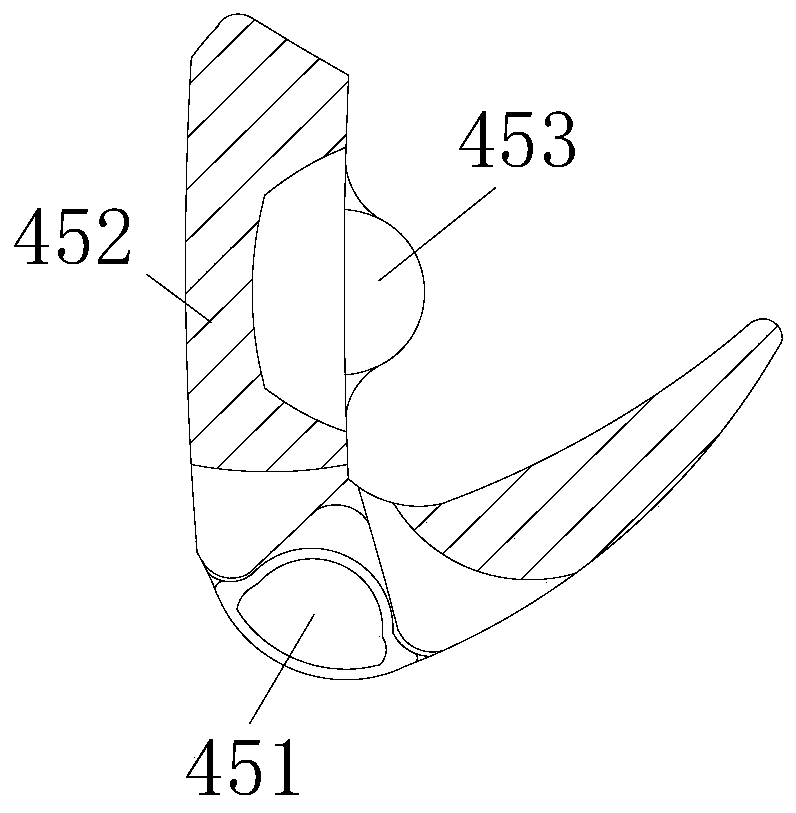

[0031] The thick wire anti-wear interface 4 includes a connecting channel 41, an anti-wearing strut 42, a wear-resistant layer 43, an active groove 44, and a stress prevention rod 45. The connecting channel 41 is installed between the active grooves 44, and the The force preventin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com