Dust detection cleaning device

A cleaning device, dust detection technology, applied in measurement devices, optical testing flaws/defects, instruments, etc., can solve problems such as failure to completely solve, cleaning equipment pollution, affecting yield, etc., to change the waste of water resources and change the environment. Pollution, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to enable those skilled in the art to better understand the technical solution of the present invention, the product of the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

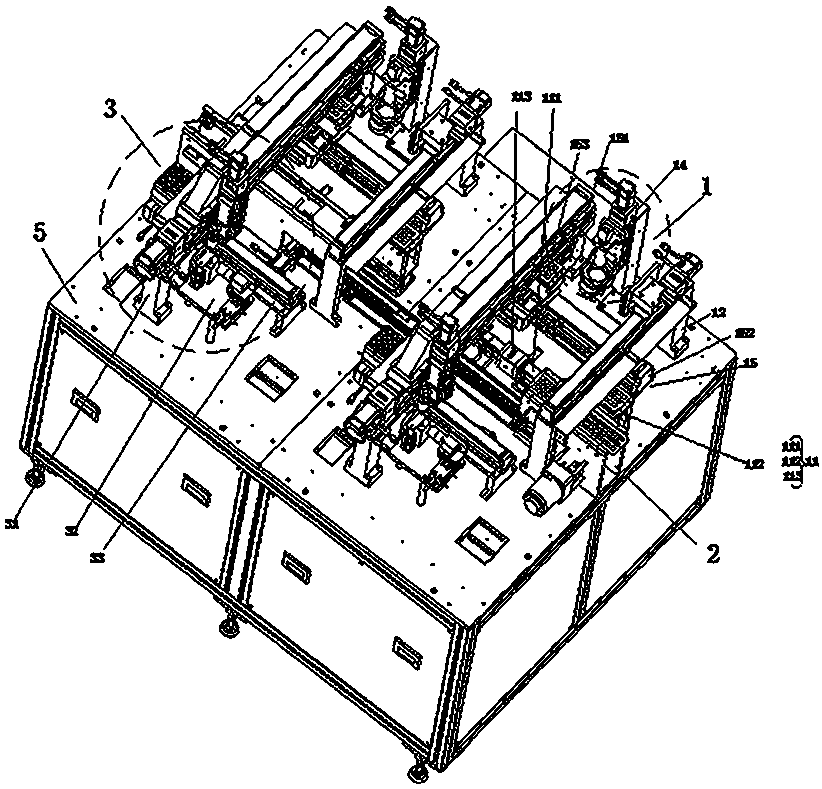

[0036] Such as figure 1 As shown, a dust detection and cleaning device is characterized in that: the device is provided with a machine platform 5, and the detection device 1 and the cleaning device 3 are arranged side by side on the said machine platform 5, and the detection device 1 and the cleaning device 3 are provided with There is a component transfer device 2;

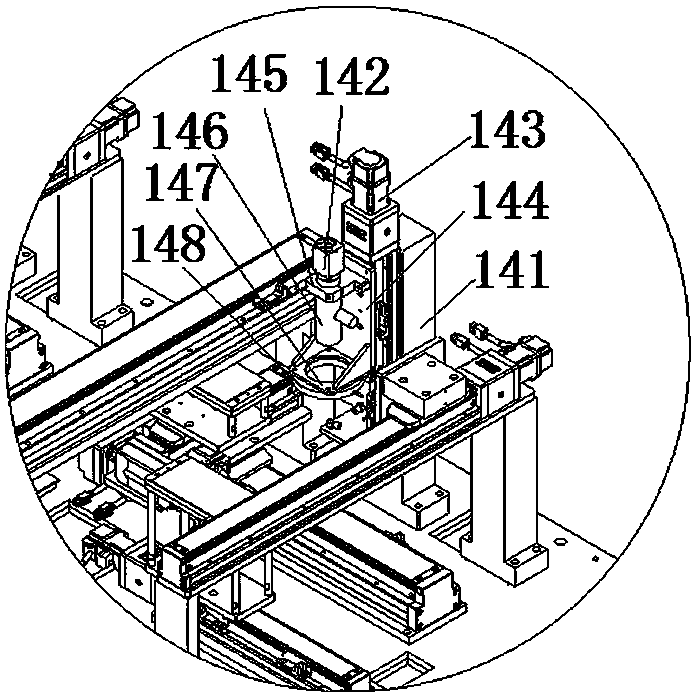

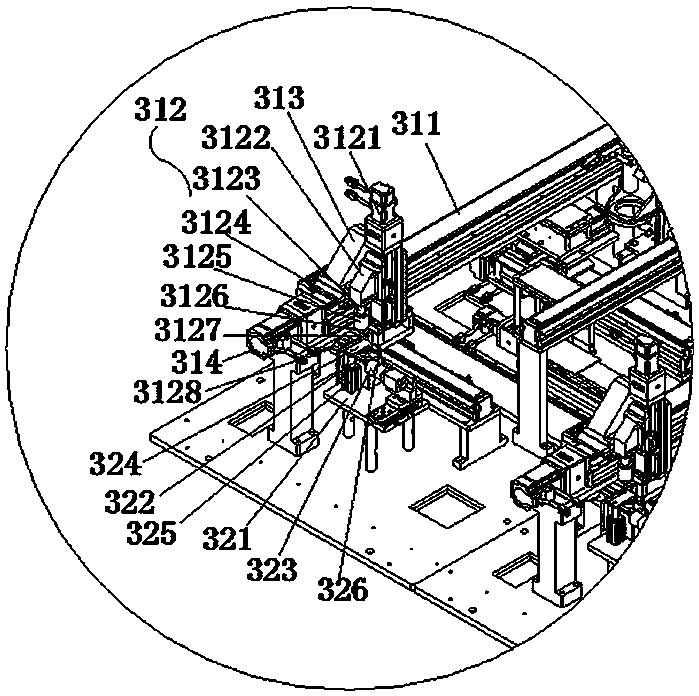

[0037] The detection device 1 includes a component transfer mechanism 11, a component moving mechanism 12, a position detection module 13, a dust detection mechanism 14 and a component carrying mechanism 15, the component transfer mechanism 11 and the component carrying mechanism 15 are arranged in parallel, and the dust detection mechanism 14 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com