An automatic measuring system for plate thickness deformation resistance

A deformation resistance and automatic measurement technology, applied in the direction of measuring devices, analysis materials, instruments, etc., can solve the problems of high requirements of the test system, poor centering, poor force, etc., and achieve the effect of changing the compression area and good centering effect , the effect of reducing functional requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

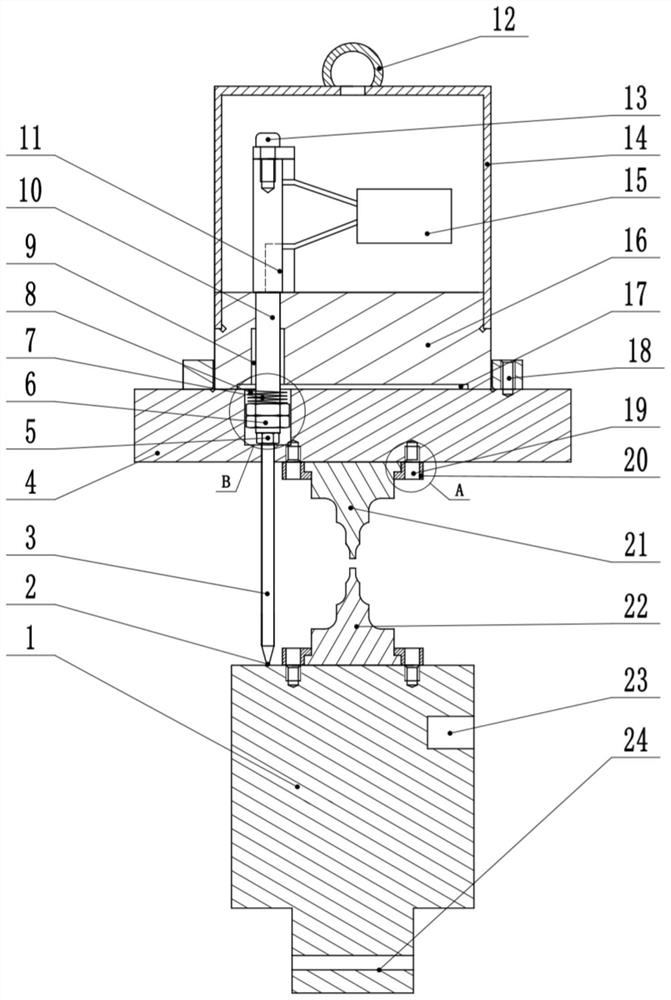

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation examples,

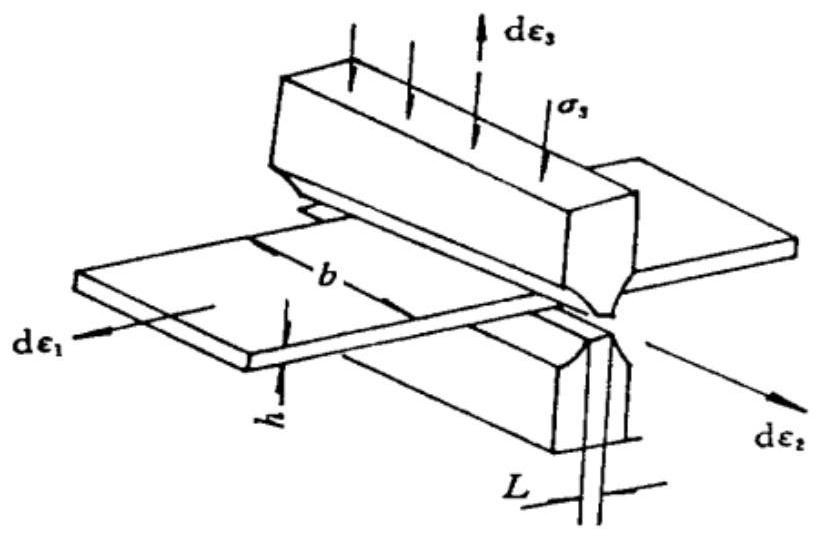

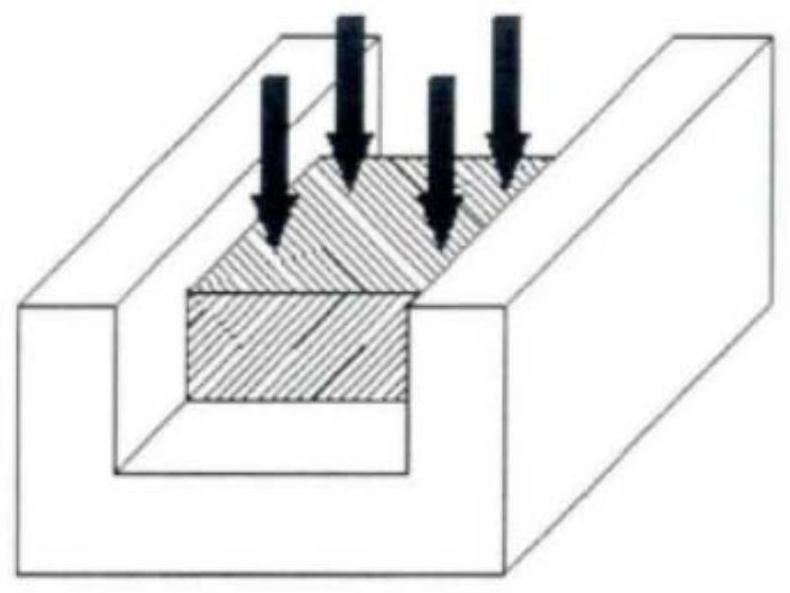

[0041] Such as Figure 3-6 As shown, the present invention discloses an automatic detection mold for the thickness-direction deformation resistance test of the plate.

[0042] Such as image 3 As shown, the assembly structure of the deformation resistance test mold of the present invention is: the compression die 4 adopts a disk shape, is located above the test piece, and bolt holes 18 are evenly distributed around it, and the assembly is completed by fixing the bolts with the testing machine. The compression punch 1 is located below the test piece and adopts the same structure as the compression die. Set the same upper and lower compression block installation structures above the punch 1 and below the die 5 that are in contact with the test piece. Wherein at the connection between the die 4 and the upper compression block 21, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com