Vertical axis and moving blades combined windmill

A technology with movable blades and vertical shafts, which is applied to wind turbines, motors, wind turbines, etc. at right angles to the wind direction. It can solve the problems of manufacturing large windmills, overloading of generators, unreasonable structures, etc., and achieves low cost and enhanced High stability and wind energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

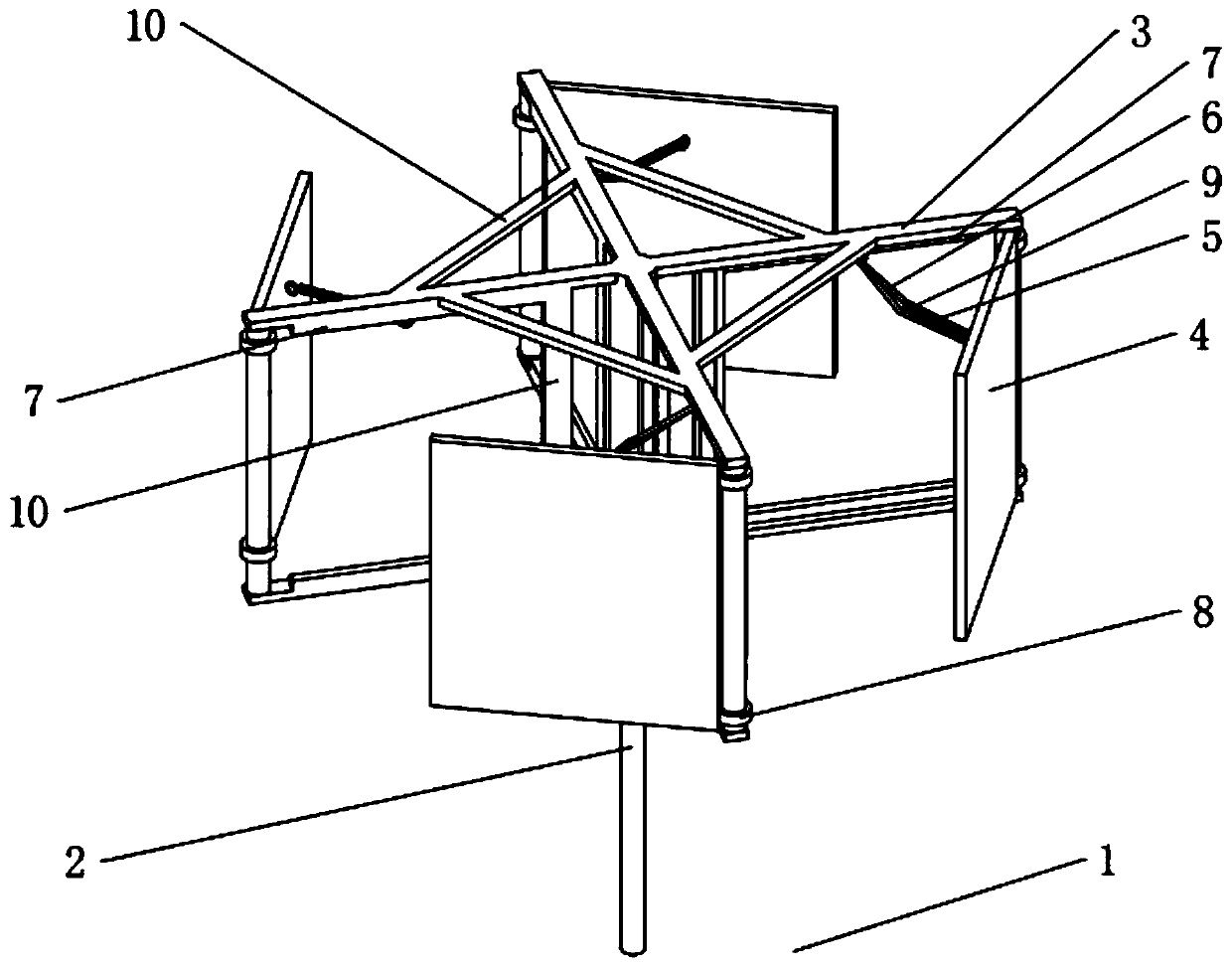

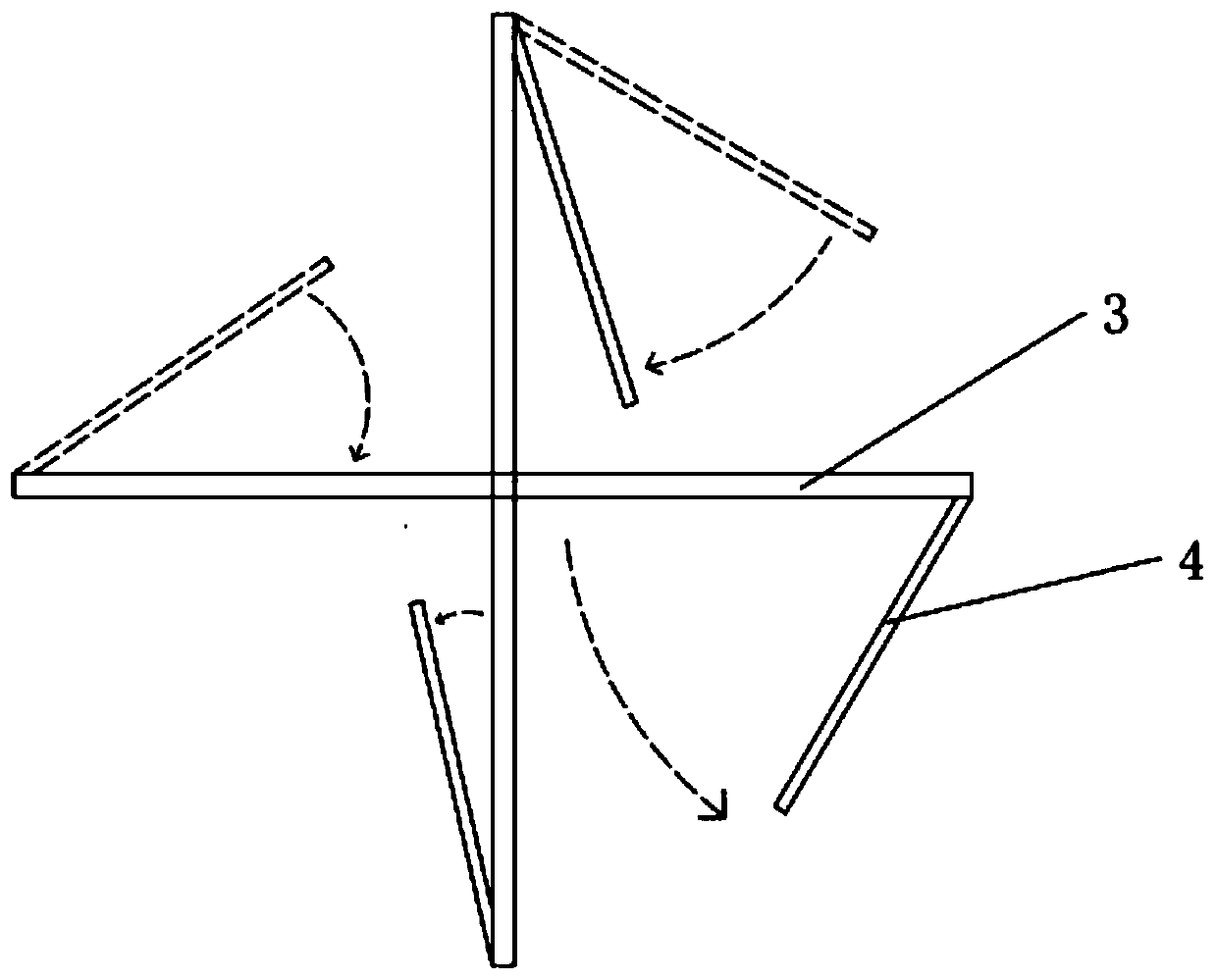

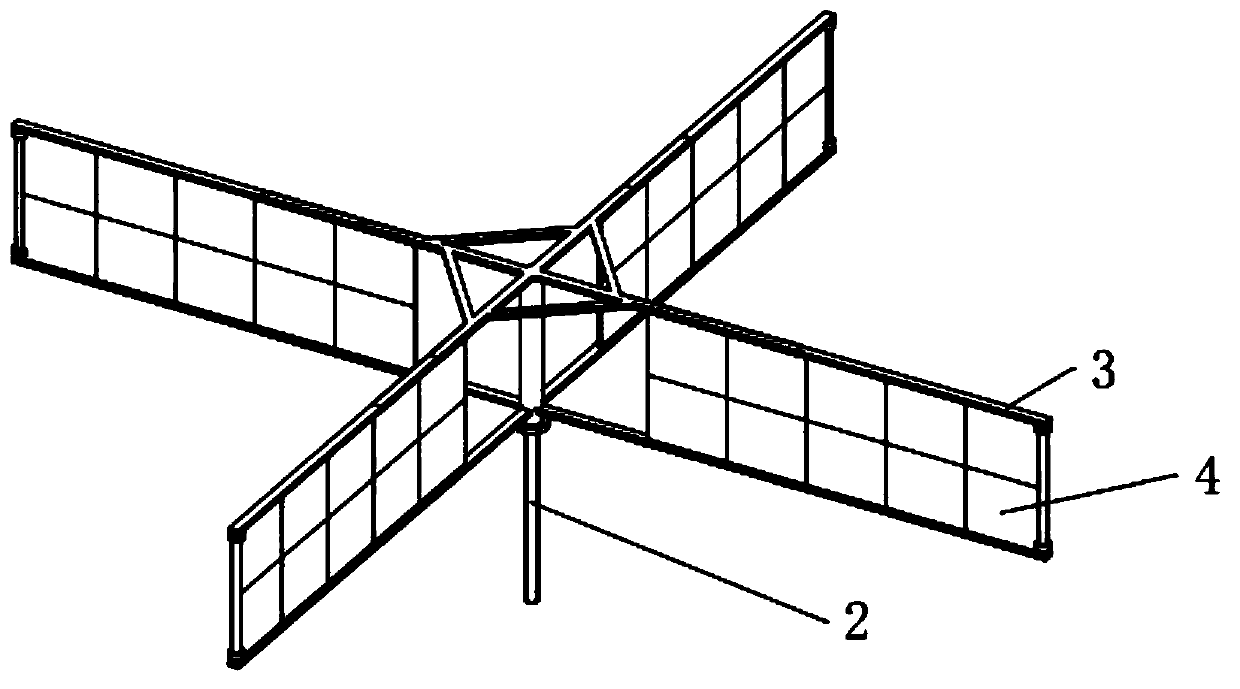

[0045] combine Figure 1-5 , differs from Embodiment 1 in that the blade 4 is hinged on the mounting frame 3 with a rotating shaft along the horizontal direction and is hinged on the inside of the top end of the mounting frame 3. When working, the blades 4 on both sides perpendicular to the wind direction, one piece in the wind close under the pressure of the wind, and the other sheet is blown up under the pressure of the wind, which also reaches the effect of embodiment one.

Embodiment 3

[0047] combine Image 6, the difference from the first embodiment is that the blade 4 is provided with an elastic window 11, and the elastic window 11 is installed with an elastic plate 12 larger than the elastic window 11, and the elastic plate 12 is arranged on the blade 4 close to the flange 7, the spring 13 is fixedly connected to the side of the elastic plate 12 away from the elastic window 11, and the end of the spring 13 away from the elastic plate 12 is fixedly connected to a fixed plate 14 fixedly installed on the blade 4 and the elastic plate 12 The spring 13 is in a compressed state when abutting on the blade 4 . In case of strong wind, the elastic window 11 can automatically open the elastic sheet 12 under the action of the spring 13, thereby reducing the pressure area of the blade 4, thereby limiting the speed of the windmill 4 and thus limiting the maximum power. It is not necessary to use brakes to protect itself and avoid power generation The machine is over...

Embodiment 4

[0049] combine image 3 with Figure 7 The difference from Embodiment 1 is that a roller 15 is fixedly installed at the bottom of the end of the mounting frame 3 away from the support shaft 2, and an arc-shaped slide rail 16 that cooperates with the roller 15 when the blade 4 rotates is fixedly connected to the ground 1. , so that the opening and closing of the blade 4 is smooth, and the force at both ends can enhance the stability of the blade 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com