Multi-channel siphon toilet bowl

A toilet, siphon technology, applied in the field of sanitary ware, can solve the problems of product process influence, difficult to obtain effective control, etc., to achieve the effect of stable function and improved function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

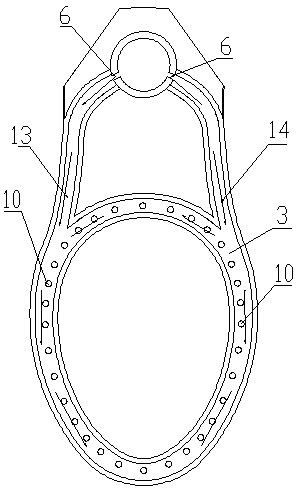

[0017] The work process of embodiment one is: after current enters from sink hole 2, current is divided into three parts, and a part is the left circle waterway 13, and a part is the right circle waterway 14, and a part is attached waterway waterway. Part of the water flow entering the gutter 11 from the gutter hole 2 enters the left gutter waterway 13 and the right gutter waterway 14 on the left and right sides through the loop hole 6, and the other part of the water flow entering from the gutter hole 2 passes through the water inlet hole of the gutter 11 7 into the attached waterway 5. The flushing water passing through the ring 3 flows into the pot body 9 through the ring eye 10 to flush the pot body 9 . The flushing water of the attached water channel 5 is flushed out through the injection hole 4 to realize flushing. Finally, the flushing water for flushing the pot body and the water flow flushed out of the spray hole converge together, and the dirt is removed outside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com