A heat treatment method for ultra-low temperature high-strength steel for compressors

A heat treatment method and high-strength steel technology, applied in the field of heat treatment technology, can solve the problems that the strength and plastic impact toughness cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In this embodiment, the workpiece to be heat-treated is a workpiece made of 25Cr2Ni3Mo steel with a maximum diameter of Φ210mm.

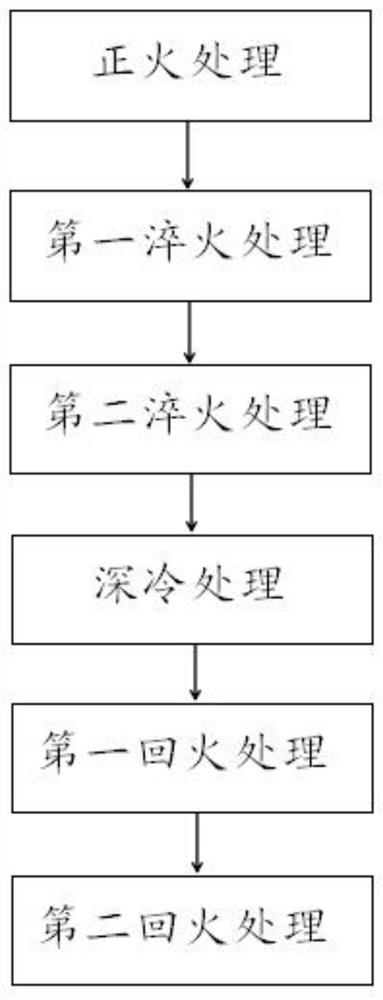

[0034] A heat treatment method for ultra-low temperature high-strength steel for compressors, comprising:

[0035] S100. Normalizing treatment: heat the furnace temperature to 900°C, put 25Cr2Ni3Mo steel into the furnace, heat the 25Cr2Ni3Mo steel to 910°C at a heating rate of 100°C / hour, and the holding time is 7 hours for effective thickness mm / 25mm , out of the oven and air-cooled;

[0036] S200, the first quenching treatment: heat the furnace temperature to 880°C, put 25Cr2Ni3Mo steel into the furnace, heat the 25Cr2Ni3Mo steel to 880°C at a heating rate of 100°C / hour, the holding time is effective thickness mm / 25mm hours, and the holding time is After 7 hours, use 8%-10% PAG solution oil to cool below 50°C, and then air cool to room temperature;

[0037] S300, the second quenching treatment: heat the furnace temperature to 820°C, put 2...

Embodiment 2

[0045] In this embodiment, the workpiece to be heat-treated is a workpiece made of 25Cr2Ni3Mo steel with a maximum diameter of Φ50 mm.

[0046] A heat treatment method for ultra-low temperature high-strength steel for compressors, comprising:

[0047] S100. Normalizing treatment: heat the furnace temperature to 890°C, put 25Cr2Ni3Mo steel into the furnace, heat the 25Cr2Ni3Mo steel to 910°C at a heating rate of 90°C / hour, and the holding time is effective thickness mm / 30mm hours, and the holding time is 1.5 hours , out of the oven and air-cooled;

[0048] S200, the first quenching treatment: heat the furnace temperature to 870°C, put 25Cr2Ni3Mo steel into the furnace, heat the 25Cr2Ni3Mo steel to 890°C at a heating rate of 100°C / hour, the holding time is effective thickness mm / 27mm hours, and the holding time is After 1.5 hours, use 8%-10% PAG solution oil to cool below 50°C, and then air cool to room temperature;

[0049] S300, the second quenching treatment: heat the furna...

Embodiment 3

[0057] In this embodiment, the workpiece to be heat-treated is a workpiece made of 25Cr2Ni3Mo steel with a maximum diameter of Φ80 mm.

[0058] A heat treatment method for ultra-low temperature high-strength steel for compressors, comprising:

[0059] S100. Normalizing treatment: heat the furnace temperature to 870°C, put 25Cr2Ni3Mo steel into the furnace, heat the 25Cr2Ni3Mo steel to 920°C at a heating rate of 95°C / hour, and keep the holding time for effective thickness mm / 29mm for 2 hours. , out of the oven and air-cooled;

[0060] S200, the first quenching treatment: heat the furnace temperature to 860°C, put 25Cr2Ni3Mo steel into the furnace, heat the 25Cr2Ni3Mo steel to 880°C at a heating rate of 100°C / hour, the holding time is effective thickness mm / 25mm hours, and the holding time is After 2 hours, use 8%-10% PAG solution oil to cool to below 50°C, and then air cool to room temperature;

[0061] S300, the second quenching treatment: heat the furnace temperature to 810...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com