Brick blank grouping and transporting device of secondary stacking burning system

A secondary code and adobe technology, which is applied in the field of adobe grouping and adobe transporting devices, can solve the problems of poor adobe stacking effect and achieve the effect of improving the effect and realizing automatic adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is further described in detail through specific implementation methods:

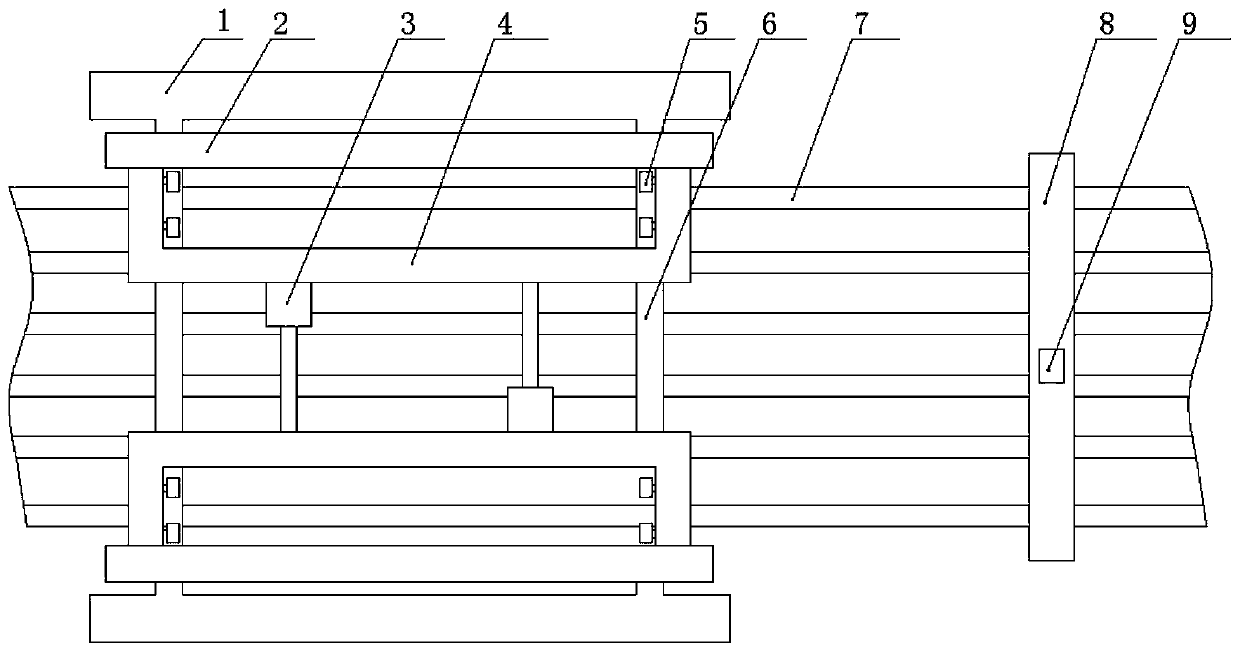

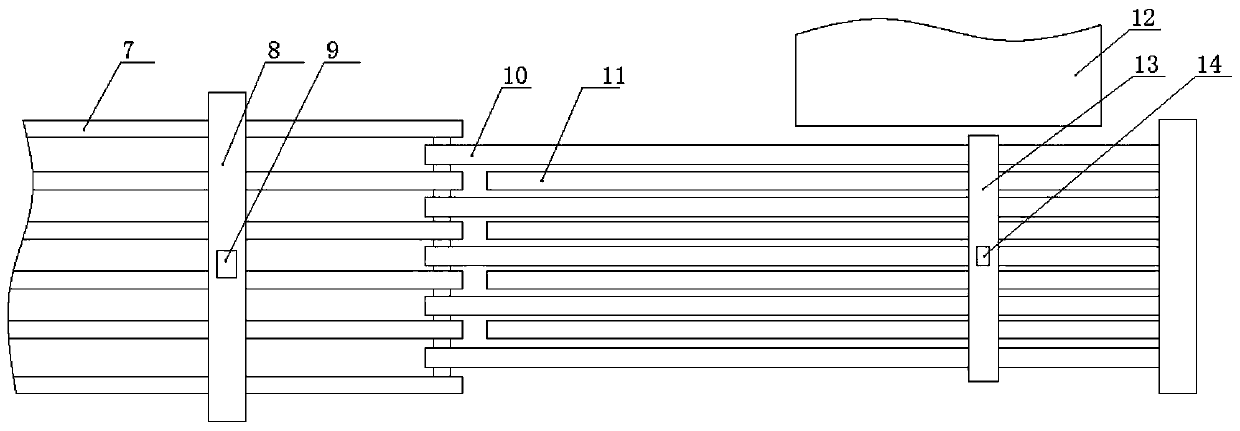

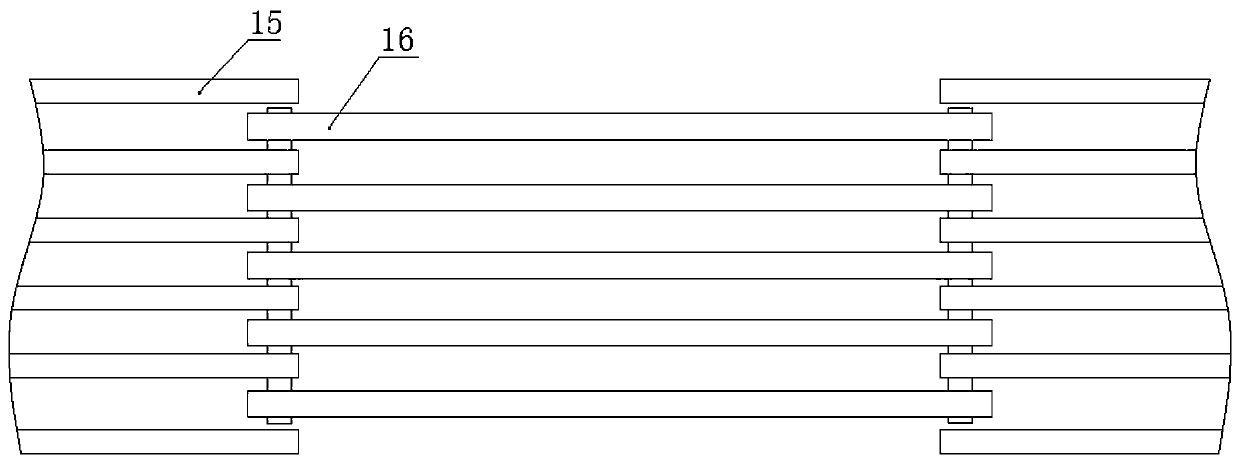

[0024] The reference signs in the drawings of the specification include: guide frame 1, splint 2, seam elimination cylinder 3, connecting frame 4, pulley 5, guide rail 6, seam elimination conveyor belt 7, limit roller 8, limit cylinder 9, seam separation conveyor belt 10. Conveyor roller 11, feeding conveyor belt 12, reference roller 13, reference cylinder 14, conveyor belt group 15, receiving conveyor belt 16, counterweight wheel 18, swing rod 19, bracket 20, connecting rod 21, lifting cylinder 22, positioning shaft twenty three.

[0025] Such as figure 1 As shown, the adobe marshalling and conveying device of the secondary code burning system includes a frame on which a seam elimination mechanism is installed. A limit roller 8 is arranged along its width direction, and a limit cylinder 9 driving it to move up and down is connected above the limit roller 8, and the limit cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com