Wheel hub die casting carrying six-axis industrial robot

A technology for industrial robots and die-casting parts, which is used in manipulators, manufacturing tools, program-controlled manipulators, etc. to achieve the effects of high operation accuracy, convenient operation and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

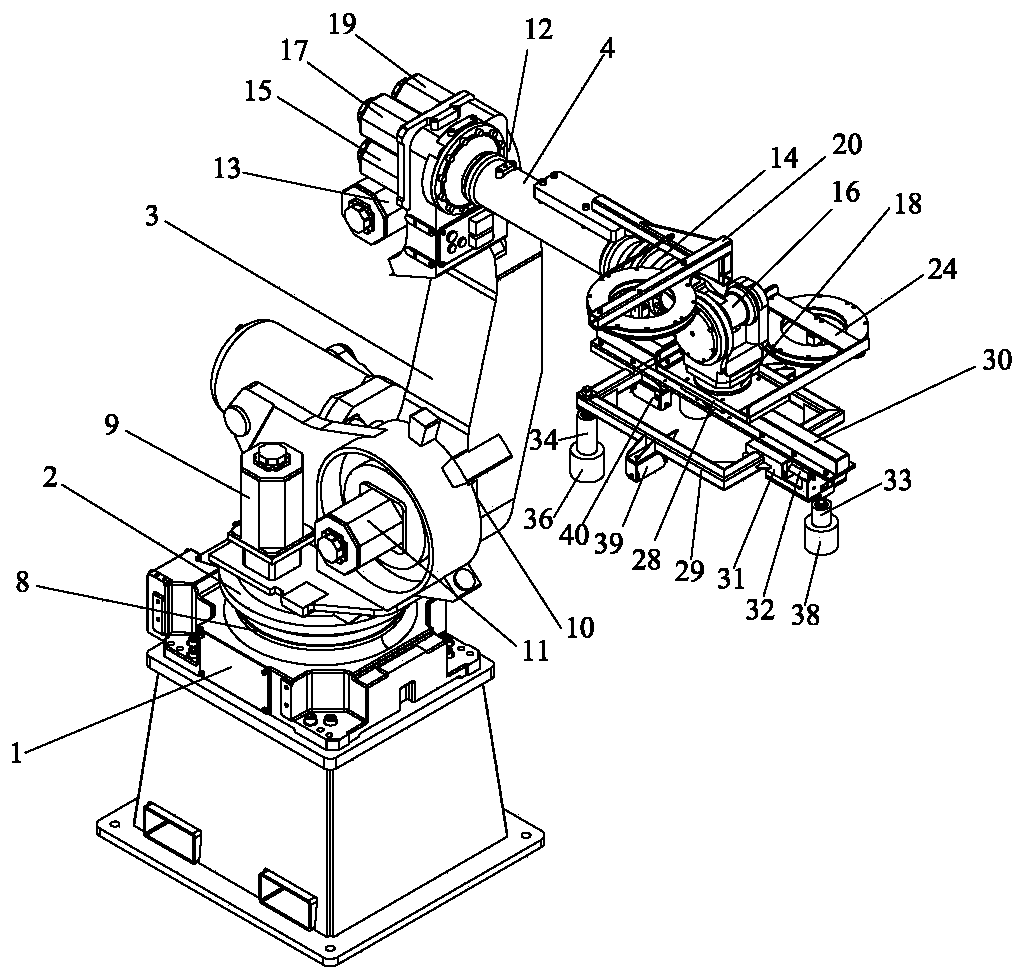

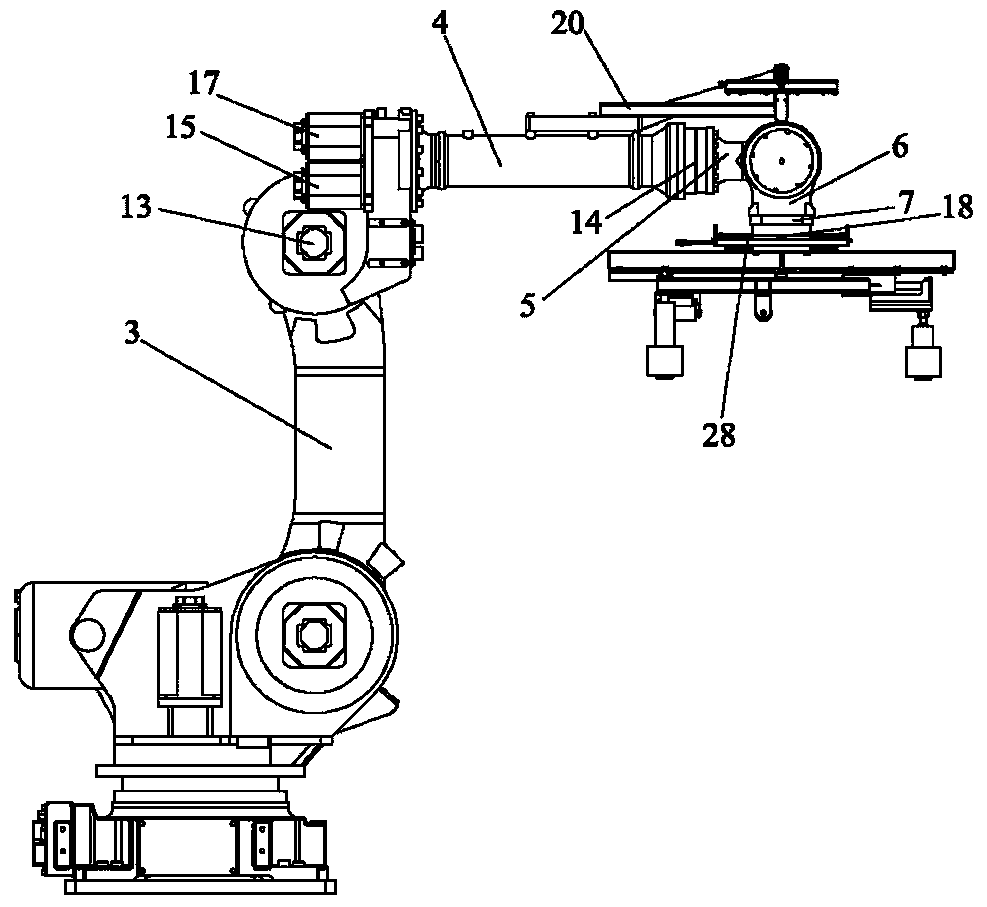

[0020] like Figure 1-4 As shown in the present invention, a six-axis industrial robot for handling wheel hub die castings includes a base 1, a swivel base 2, a first mechanical arm 3, a second mechanical arm 4, a third mechanical arm 5, a fourth mechanical arm 6 and a fifth mechanical arm. The mechanical arm 7, the swivel base 2 is connected to the base 1 through the first joint 8 and driven by the first drive motor 9; the first mechanical arm 3 and the swivel base 2 are connected 10 through the second joint and driven by the second The motor 11 is driven; the second mechanical arm 4 and the first mechanical arm 3 are connected by a third joint 12 and driven by a third drive motor 13; the third mechanical arm 5 and the second mechanical arm 4 are driven by a fourth The joint 14 is connected and driven by the fourth drive motor 15; the fourth mechanical arm 6 and the third mechanical arm 5 are connected by the fifth joint 16 and driven by the fifth drive motor 17; the transpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com