Ship for collecting kelps from ship side and working method thereof

A kelp and broadside technology, which is applied in the field of kelp harvesting ships, can solve the problems of high wind pressure arm, affecting the safety of the ship, raising the center of gravity of the ship, etc., and achieves the effect of small shielding effect, favorable navigation safety, and solving the effect of obstructing the line of sight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] see figure 2 , this figure draws a schematic diagram containing 2 floating raft groups. Each floating raft group has 2 culture units for illustration, and the waterway between the two floating raft groups; the horizontal harvesting method is adopted; the narrower end of the harvesting boat is the bow.

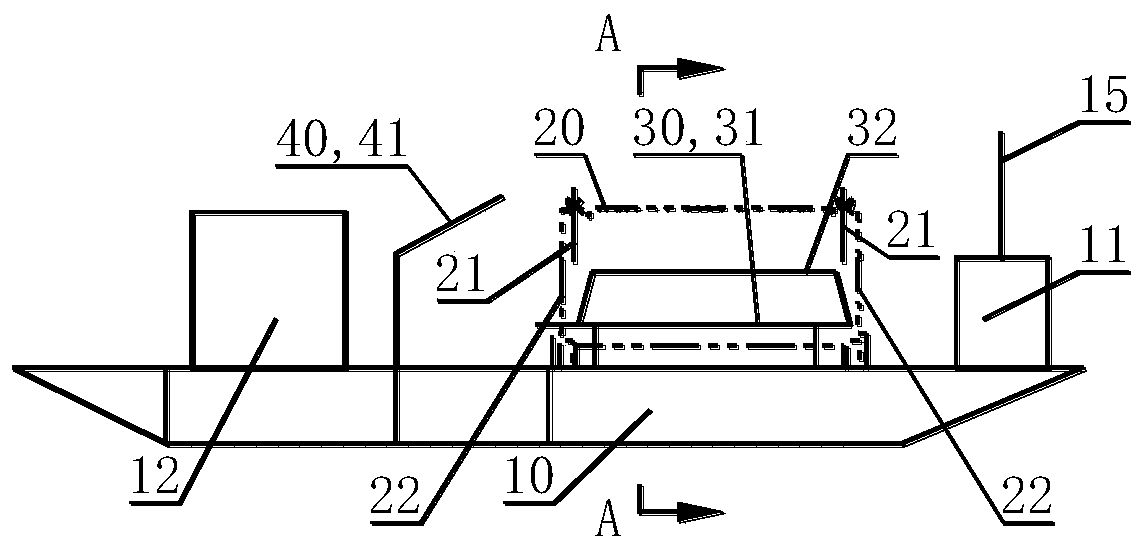

[0042] see image 3 , a kind of ship that harvests kelp from the ship's side, including a main hull 10; a cab 11 located at the bow; a cabin shed 12 located at the stern; machine 20; the kelp tip collection cabin 13 and the kelp main body collection cabin 14 that are arranged at one or both ends of the harvester; the conveyor belts 30 and 31 placed below the harvester 20 are used to carry and transport the kelp tip and the kelp main body that are cut respectively, And it is transported to kelp tip collecting compartment 13 and kelp main body collecting compartment 14; the towing direction of the towing rope 21 attached to the harvester 20, the transport direction of t...

Embodiment 2

[0046] see Figure 6-8 , Figure 6-8 It is a schematic diagram of setting up two harvesters on a ship harvesting kelp from the side of the ship. In the figure, the kelp tip collection cabin and the kelp main body collection cabin are set at the same end of the harvester, and the conveyor belt for transporting kelp tips is in the same direction as the conveyor belt for transporting kelp main body run. The rest are the same

[0047] Embodiment one.

Embodiment 3

[0049] see Figure 9-11 , Figure 9-11 It is a schematic diagram of two harvesters installed on a ship that harvests kelp from the ship's side.

[0050] Among the figure, the kelp tip collection cabin 13 and the kelp main body collection cabin 14 are placed at the two ends of the harvester, and the crane is also divided into two ends simultaneously.

[0051] All the other are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com