Inlet end support for battery conveying device

A technology for conveying devices and batteries, applied in the direction of slender components, building components, etc., can solve the problems of insufficient support strength and easy wear and tear on the surface of the bracket, and achieve the effects of improved service life, reasonable overall structure setting, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

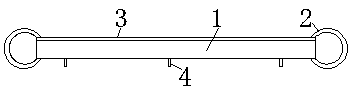

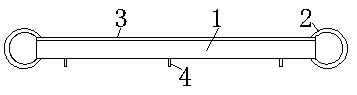

[0009] like figure 1 As shown, a battery delivery device according to the present invention uses an inlet bracket, which includes a bracket body, and the bracket body is composed of a straight body 1 and two O-shaped bodies 2, and the O-shaped body 2 is arranged on the straight 1 at both ends, a wear-resistant layer 3 is provided on one side of the straight-edge body 1 of the bracket body, and an S-shaped reinforcing rib 4 is arranged on the other side; the thickness ratio of the wear-resistant layer 3 to the straight-edge body 1 is 1 : (5-8). The overall structure of the present invention is reasonably arranged, and a wear-resistant layer is provided on one side of the straight-sided body of the bracket body, which effectively improves its wear resistance. The overall service life is improved, and the structure is simple to manufacture and meets the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com