Bottle grabbing mechanism, bottle body transfer method and pharmaceutical production equipment

A bottle body and drive mechanism technology, applied in the directions of packaging bottles, packaging items, packaging, etc., can solve the problems of increasing system energy consumption, occupying space, and large equipment size, achieving compact structure, less space, and reliable grasping action. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

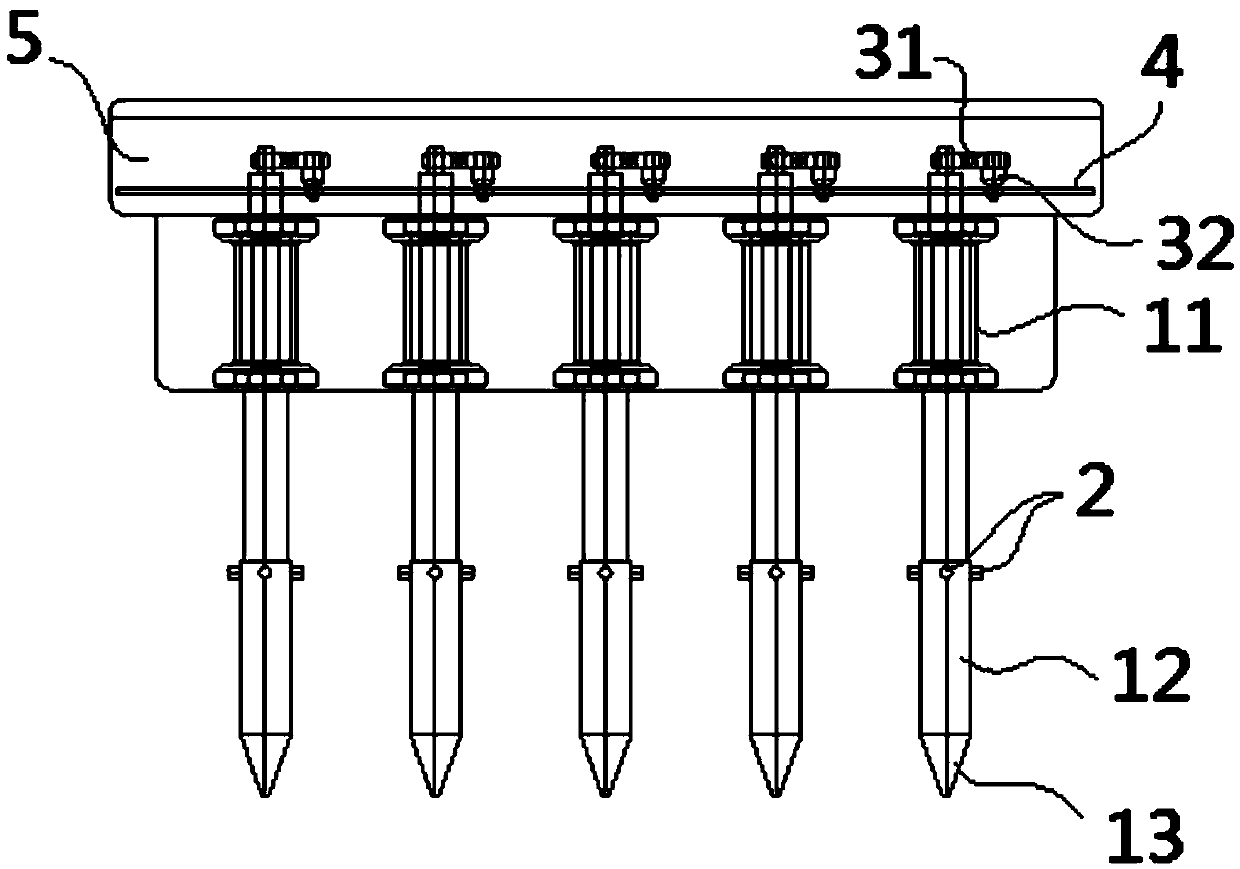

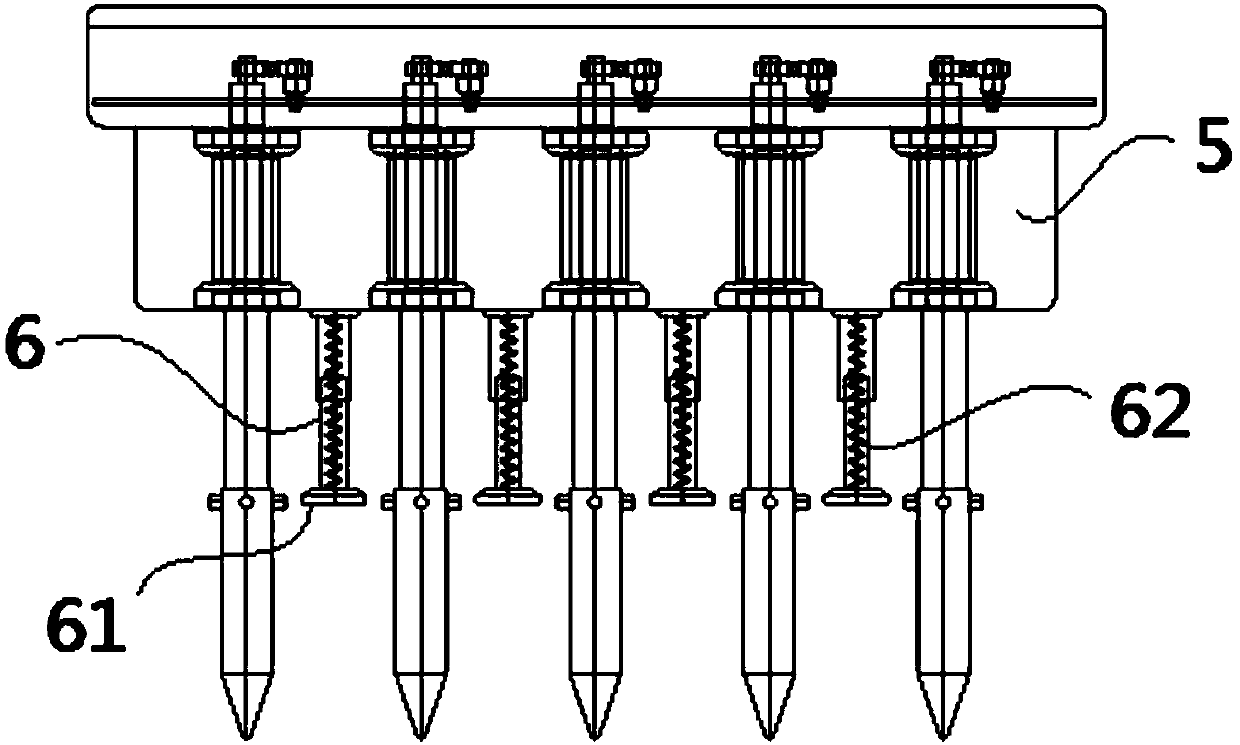

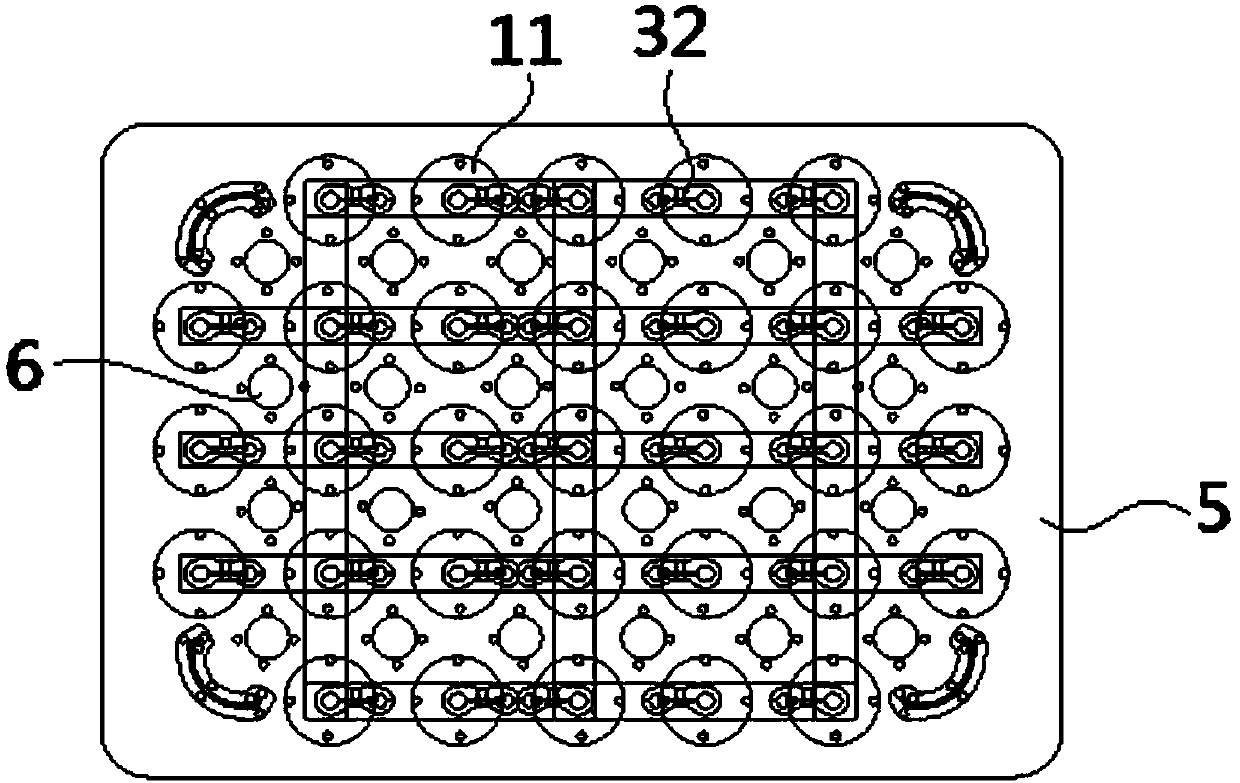

[0034] Such as figure 1 As shown, it is a structural schematic diagram of an embodiment of the bottle grasping mechanism of the present invention at a flat viewing angle. In this embodiment, the bottle grasping mechanism includes: a base body 5 and a plurality of grasping rods operatively connected to the base body 5 . The base body 5 can be used to install the grabbing rod and drive the movement of the grabbing rod. In addition, the movement of the base body 5 can also drive the grabbing rod to move accordingly.

[0035] A supporting part 2 is provided on the outer surface of the grabbing rod. refer to figure 1 , the support part 2 may include a protruding structure formed on the outer surface of the grab bar, for example including a plurality of continuous or discrete protruding structures ( figure 1 shows at lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com