Two-way rotary stirring assembly, mixer with application of assembly and operating method thereof

A technology of mixing components and bidirectional rotation, which is applied to mixers with rotating mixing devices, mixer accessories, chemical instruments and methods, etc., can solve the problems of uneven mixing and uneven mixing of upper and lower materials, and achieve uniform mixing of materials. , Improve the stirring efficiency, reduce the effect of stirring resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

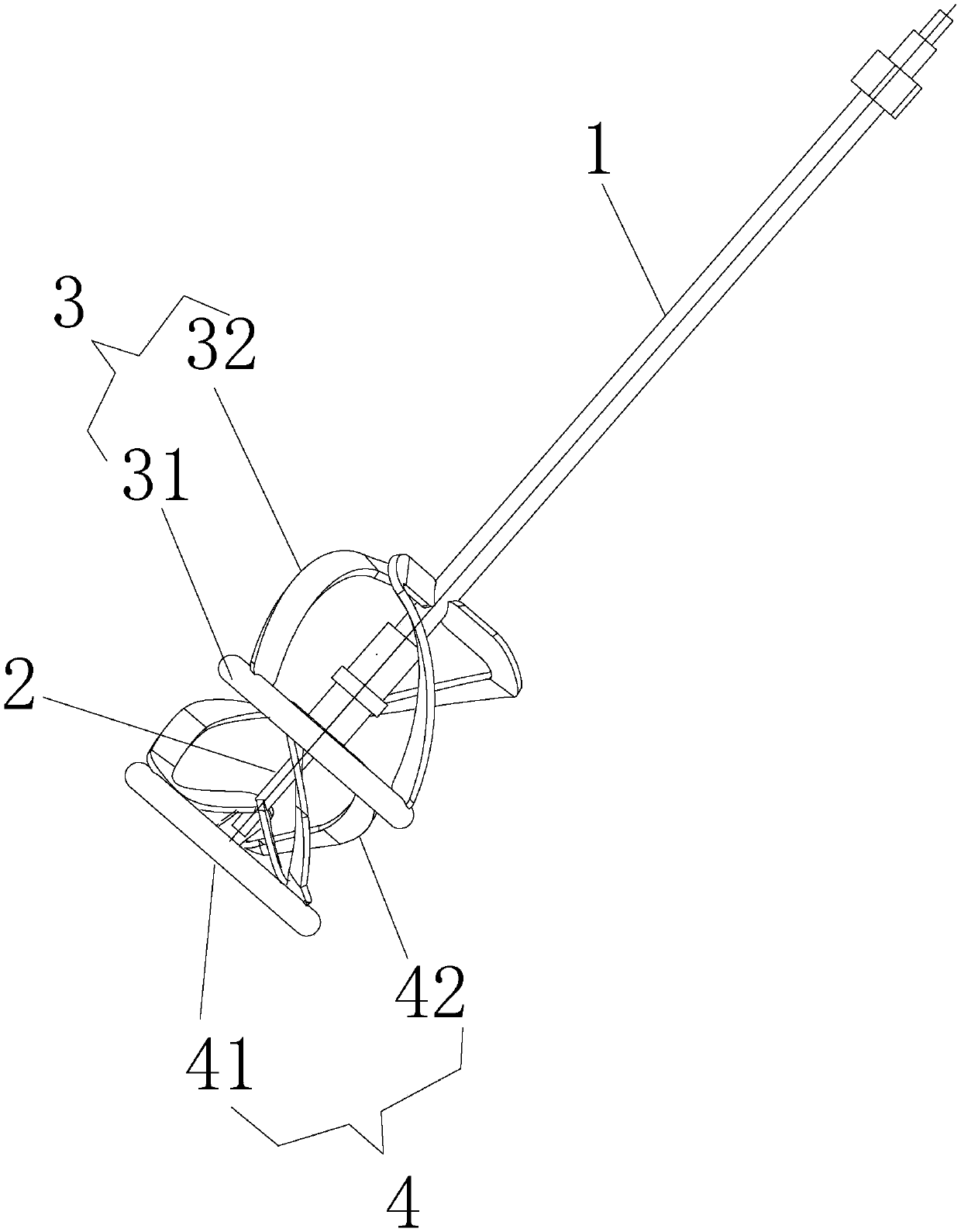

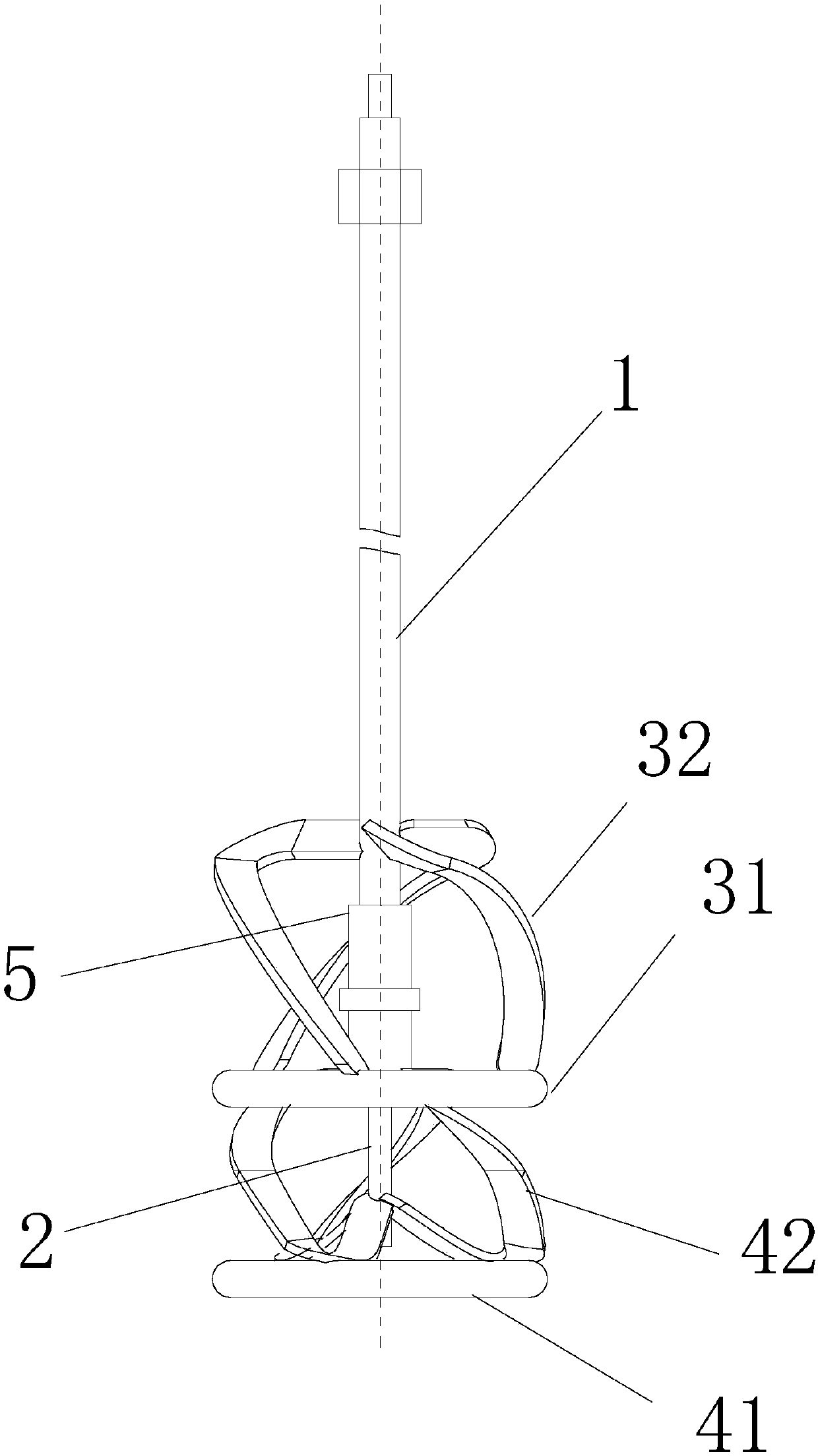

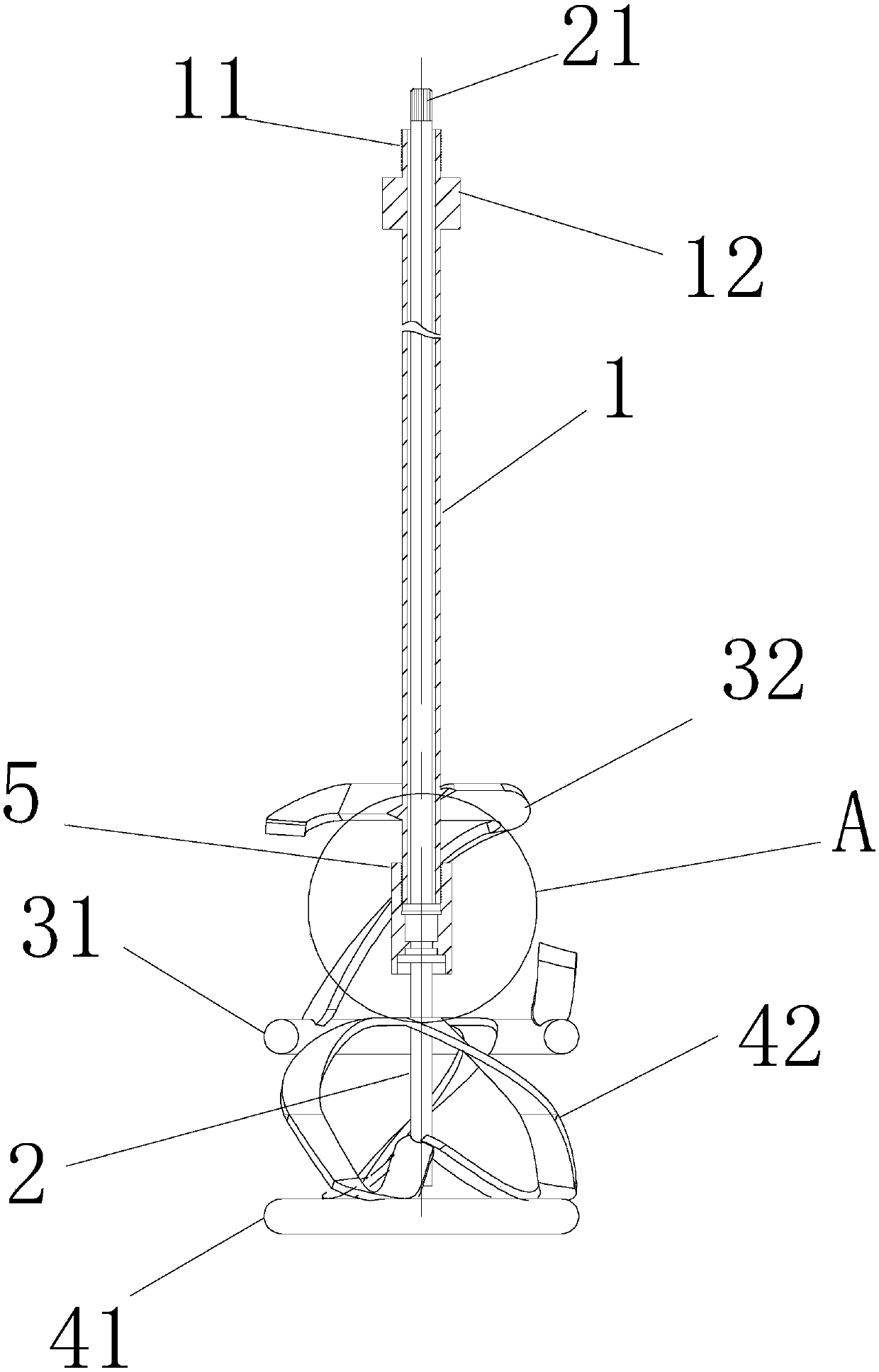

[0022] Example 1 as Figure 1 to Figure 3 As shown, the two-way rotating mixing assembly of this embodiment includes: an outer shaft sleeve 1, an inner shaft 2, and a sealed bearing assembly 5 arranged coaxially and fitted with sleeves. The top outer wall of the outer shaft sleeve 1 is provided with a connecting thread 11 and a limit The ring platform 12; the bottom of the outer shaft sleeve 1 is provided with an upper stirring assembly 2, and the upper stirring assembly 2 includes an upper supporting ring 21 and three C-shaped upper stirring blades 32, and the bottom ends of each upper stirring blade 32 are welded and fixed to the upper supporting ring 31 The top of each upper stirring blade 32 is spirally inclined inwardly and fixed by welding with the outer bushing 31, so that the upper stirring blade 32 and the upper supporting ring 31 form a cage-shaped stirring assembly and is conical, and the bottom end of the outer bushing 1 is placed The upper side of the upper suppor...

Embodiment 2

[0025] On the basis of Example 1, the two-way rotating stirring assembly of this embodiment has the following changes: the upper stirring blade and the lower stirring blade are arranged in an S shape, and the top ends of the upper stirring blade and the lower stirring blade are spirally inclined inward and correspond to the outer shaft sleeve , The inner shaft is welded and fixed, the bottom ends of the upper and lower stirring blades are respectively welded and fixed with the upper and lower supporting rings, so that the upper and lower stirring components are conical, and the upper and lower stirring blades are The spiral direction is the same.

Embodiment 3

[0027] On the basis of Embodiment 1, there are the following changes in the two-way rotating stirring assembly of the present embodiment: Figure 5 As shown, the upper stirring blade 31 is arranged in an inverted L shape, and the lower stirring blade 41 is in an S shape. The upper stirring component 3 is tower-shaped, the lower stirring component 4 is conical, and the lower stirring component 4 is placed in the upper stirring component 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com