precessing fluid turbine

A fluid and turbine technology, used in machines/engines, mechanical equipment, hydropower, etc., can solve the problem of not dealing with losses, and achieve the effect of increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

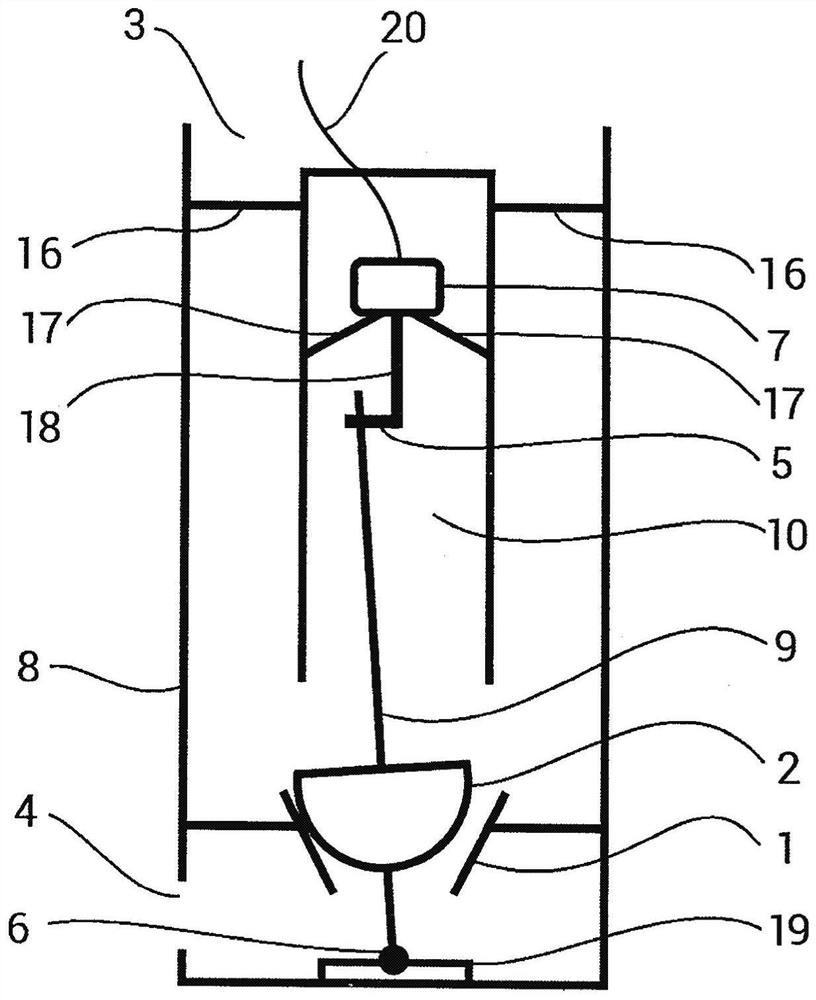

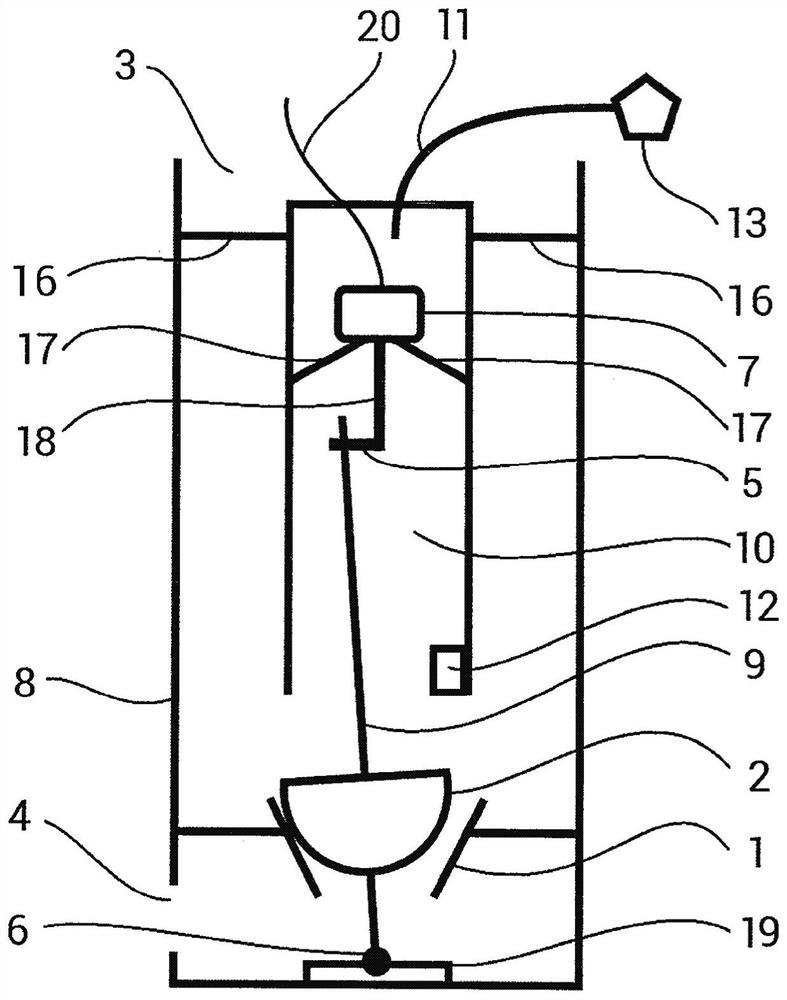

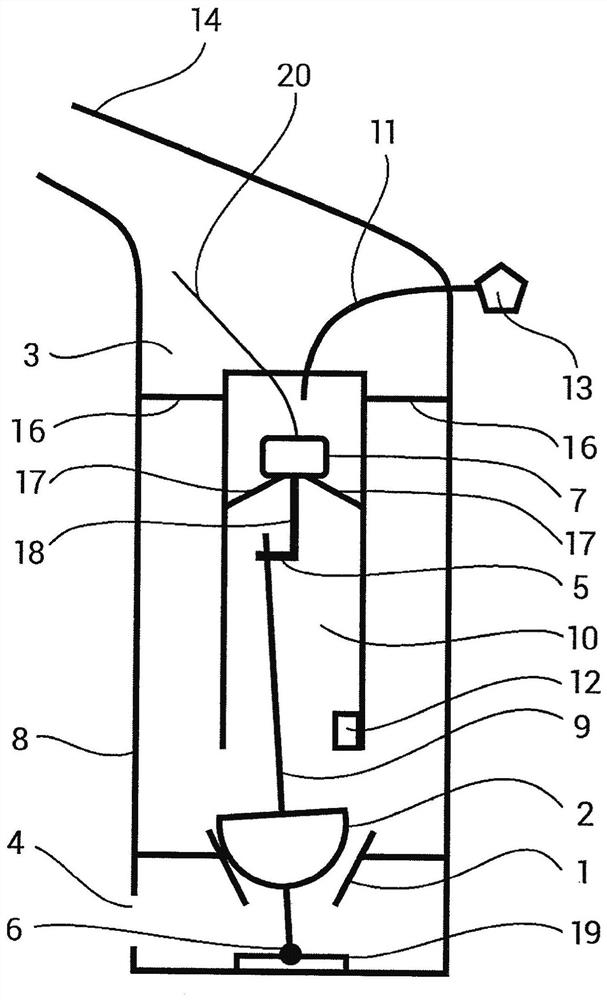

[0014] according to figure 1 The precessing fluid turbine comprises a fluid reservoir 8 having a fluid inlet opening 3 and a fluid outlet opening 4 . The stator nozzle 1 is arranged in a fluid reservoir 8 between a fluid inlet opening 3 and a fluid outlet opening 4 . Arranged in the stator nozzle 1 is a vaneless rolling rotor 2 with a shaft 9 . The rolling rotor 2 can have any shape of revolution.

[0015] The rolling rotor 2 is mounted on a holding device 6 . The retaining means 6 may consist of any known mechanism which enables the rolling rotor 2 to roll in a convoluted manner along the inner wall of the stator nozzle 1 . exist figure 1 In the embodiment of the present invention, the holding device 6 comprises a rod-shaped support firmly connected to the bottom of the rolling rotor 2 and mounted in a bracket 19 terminating in a ball joint on the opposite side.

[0016] In the fluid reservoir 8, above the rolling rotor 2 there is an air chamber 10 at least partially sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com