Array arrangement type piezoelectric energy harvester applied to non-directional flow

An array arrangement, piezoelectric energy capture technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc. and other problems, to achieve the effect of simple incentive method, improved energy capture efficiency, and extended life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

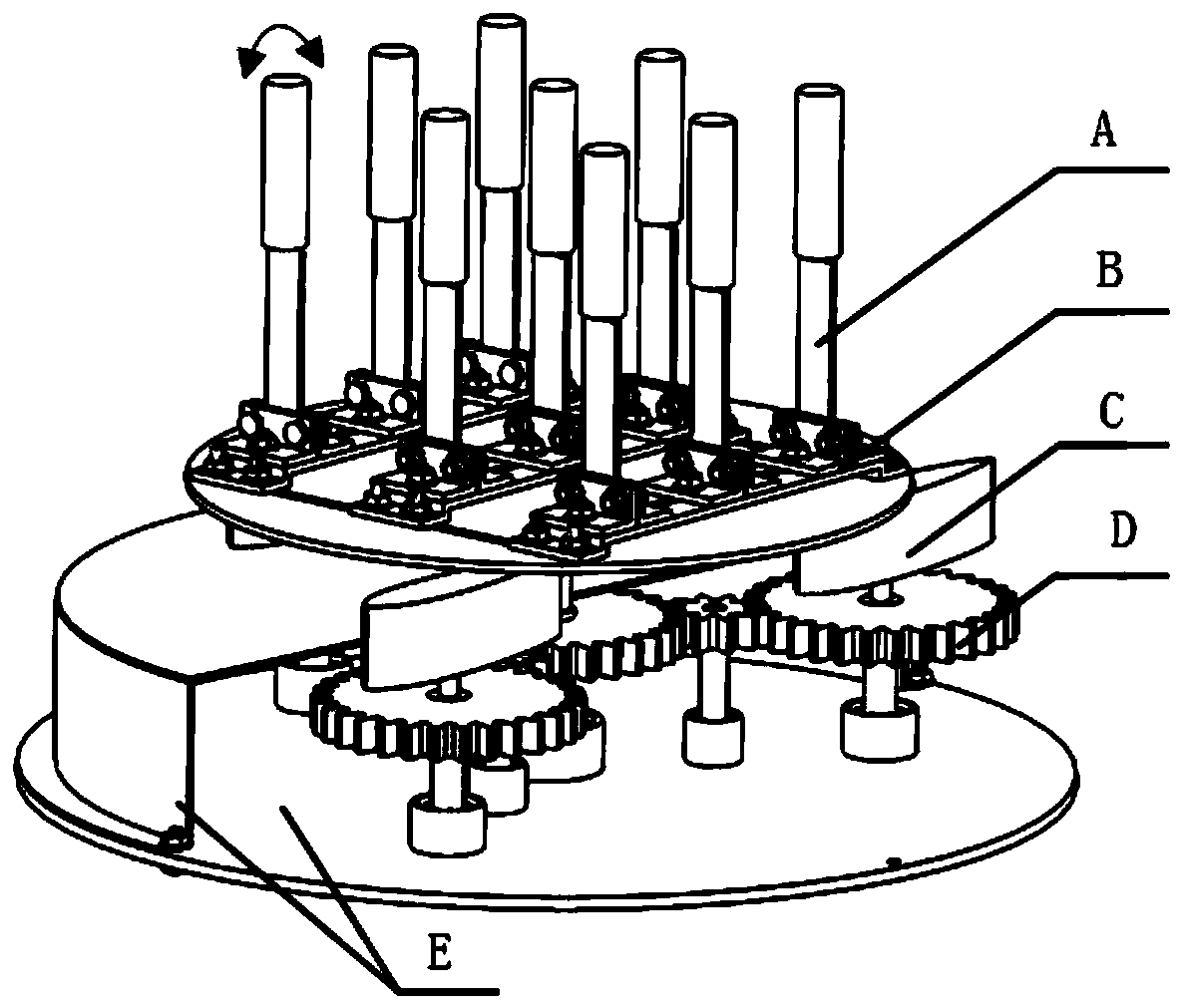

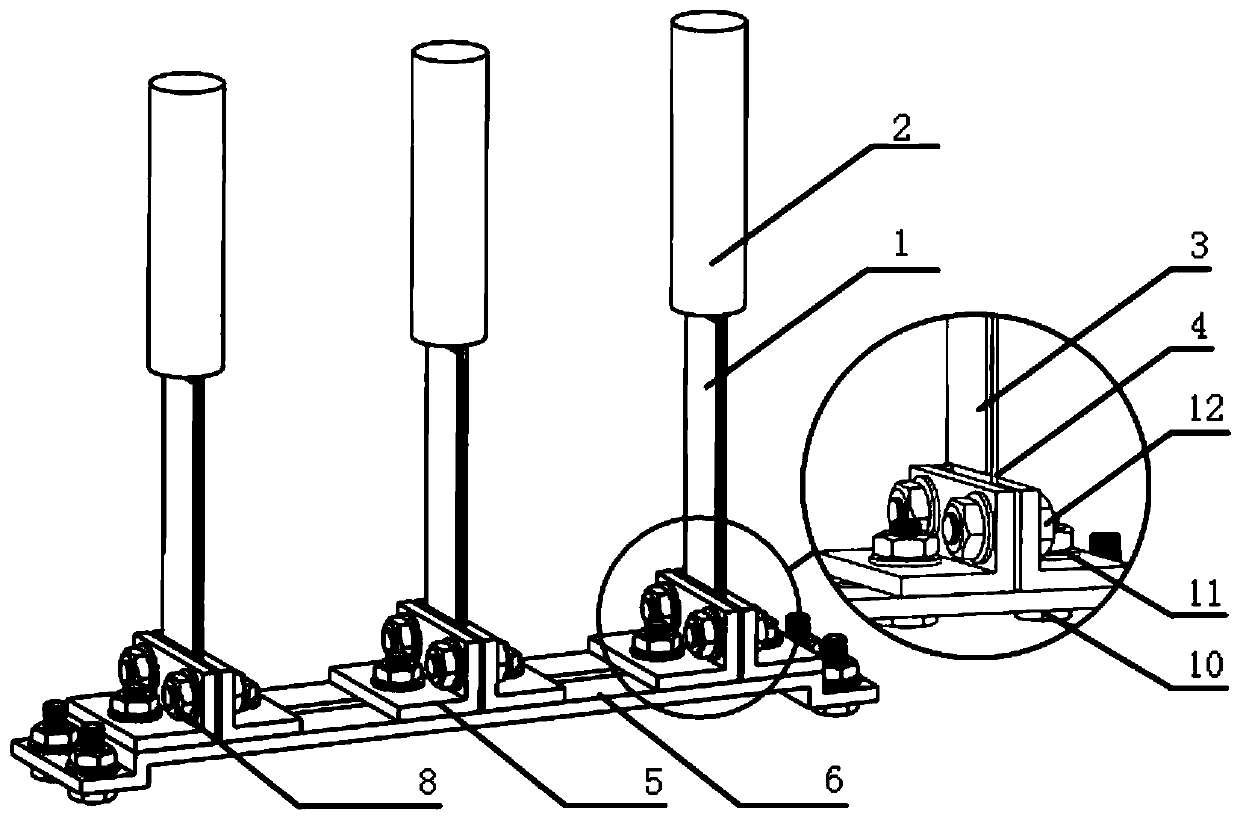

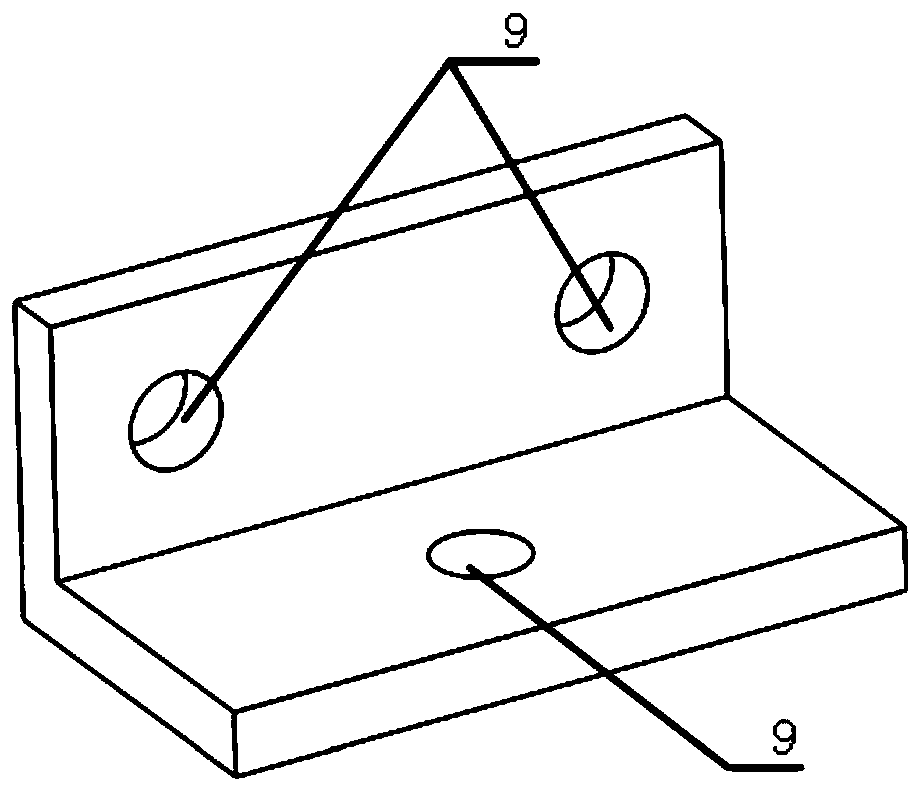

[0034] Such as Figure 1 to Figure 13 As shown, an array-arranged piezoelectric energy harvester applied to non-directional flow according to the present invention has an array form of 3*3, and specifically includes nine piezoelectric vibrators A, an array clamp mechanism B, and guide wings Mechanism C, gear transmission mechanism D and housing E; said gear transmission mechanism D is installed inside the housing E, and the gear transmission group D includes three driving gear shafts 38 and a driven gear shaft 40, and the guide wing mechanism C passes through the housing and The driving gear shaft 38 is connected, and the upper end of the driven gear shaft 40 passes through the shell E to connect with the array fixture mechanism B. The nine piezoelectric vibrators A are installed on the array fixture mechanism B, and the guide wings of the guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com