Electromagnetic brake motor

An electromagnetic brake and brake technology, applied in the direction of electric components, mechanical energy control, electrical components, etc., can solve problems such as troublesome installation, complicated installation, and difficult operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0016] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

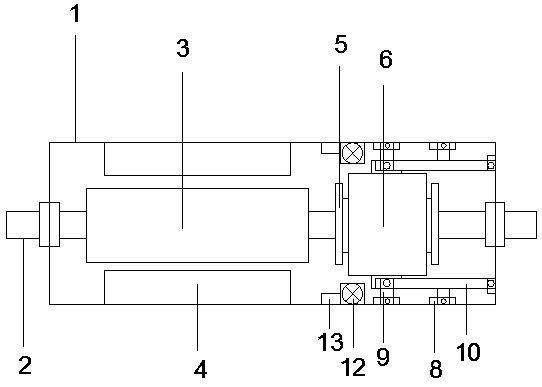

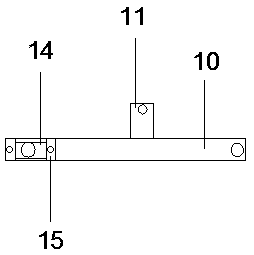

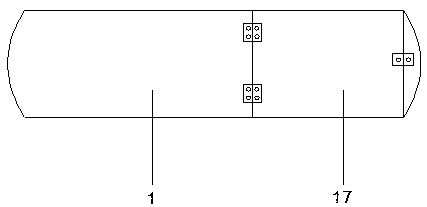

[0017] Such as Figure 1-Figure 4 As shown, this specific embodiment adopts the following technical scheme: it includes a motor housing 1, a rotating shaft 2, a rotor 3, a stator 4, a magnetic suspension bearing 5, a brake 6, a mounting block 7, a fixing block 8, a mounting plate 9, a connecting plate 10, Connecting strip 11, switch plate 17; the inner movable sleeve of the motor casing 1 is equipped with a rotating shaft 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com