Preparation method and construction method of prefabricated fracturing displacement isolator

A construction technique and isolator technology, which is applied in the field of preparation of prefabricated fracturing displacement isolators, can solve problems such as viscous fingering and over-displacement, and achieve the effect of small well control risk, simple operation method, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

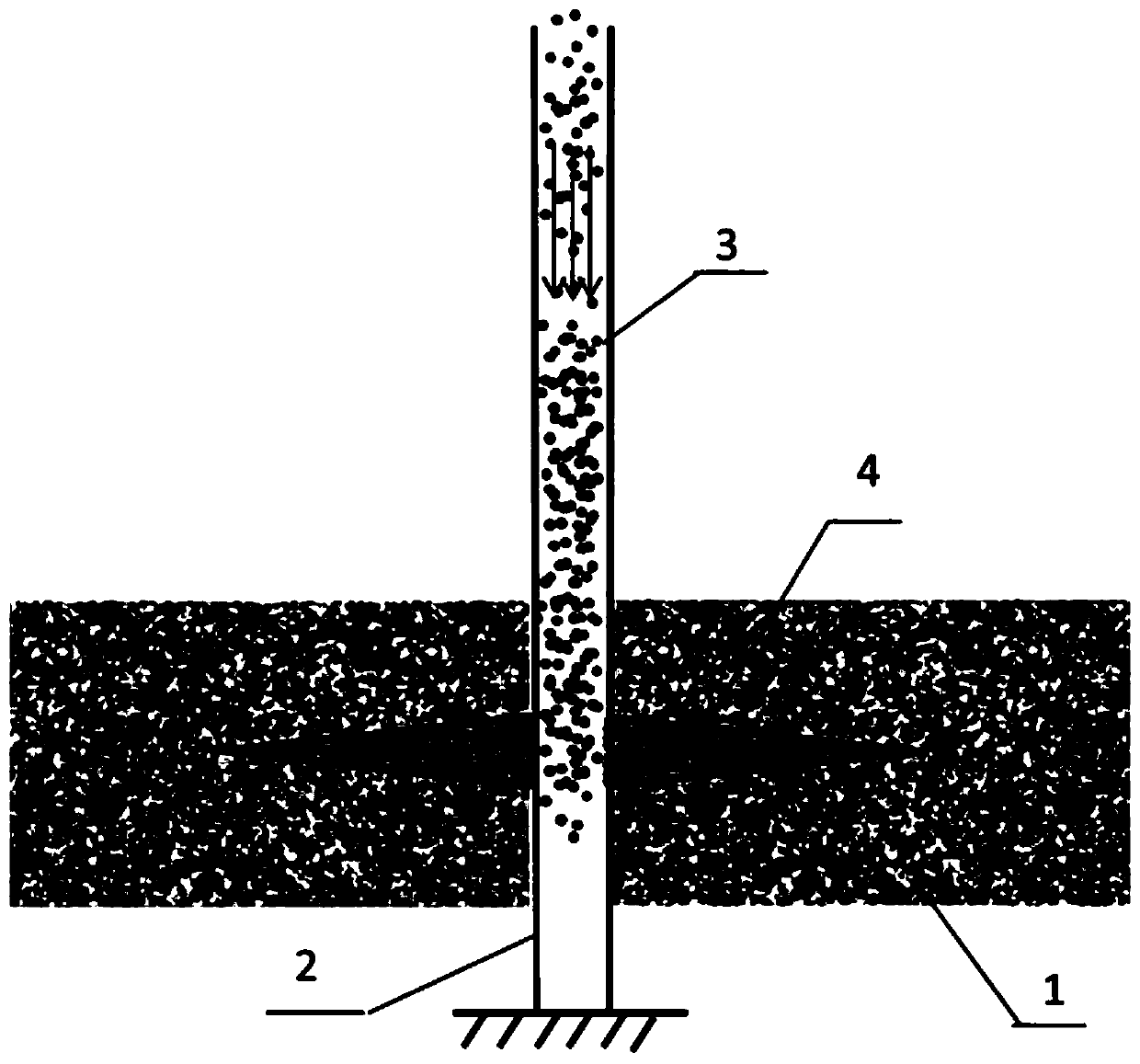

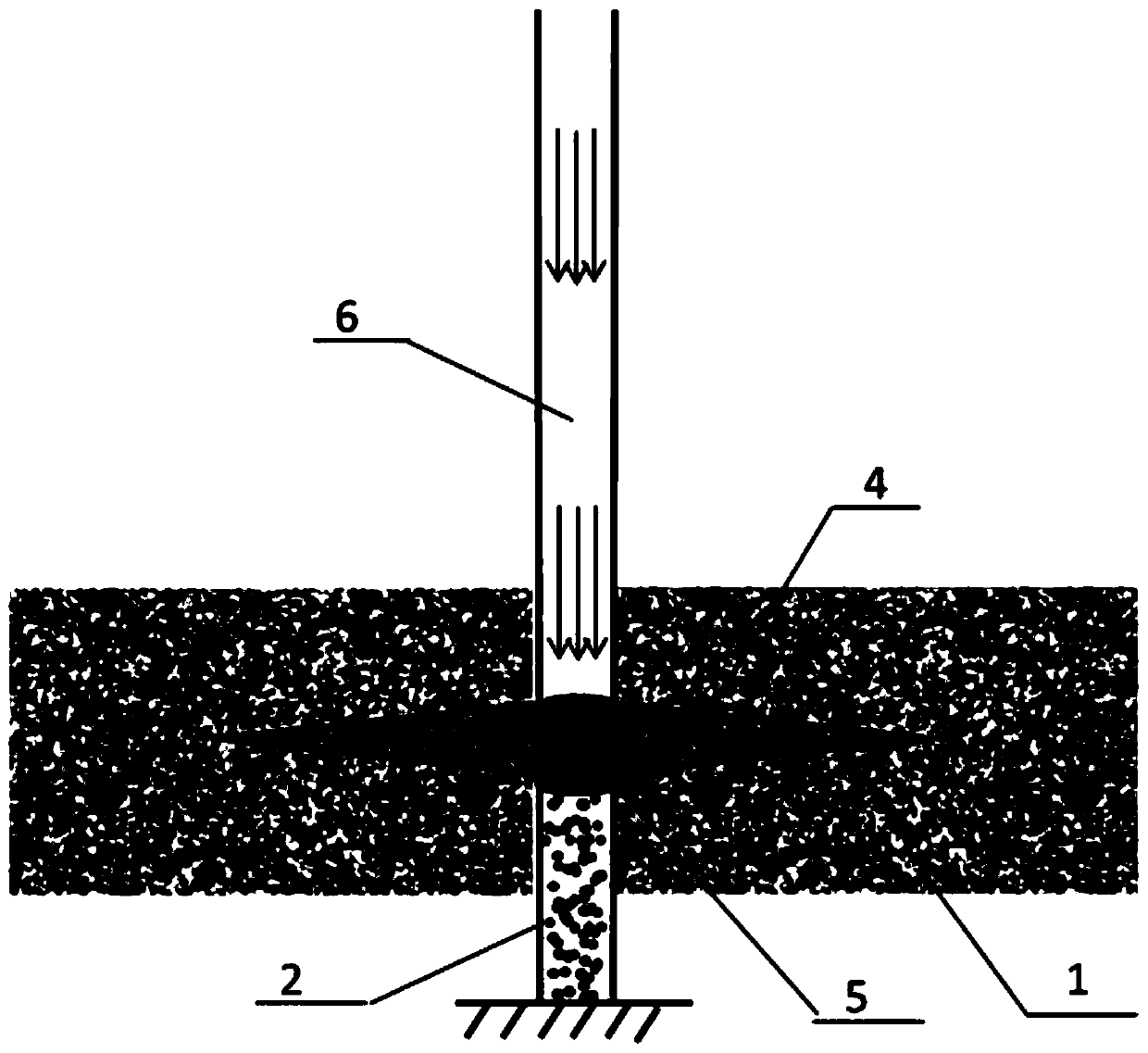

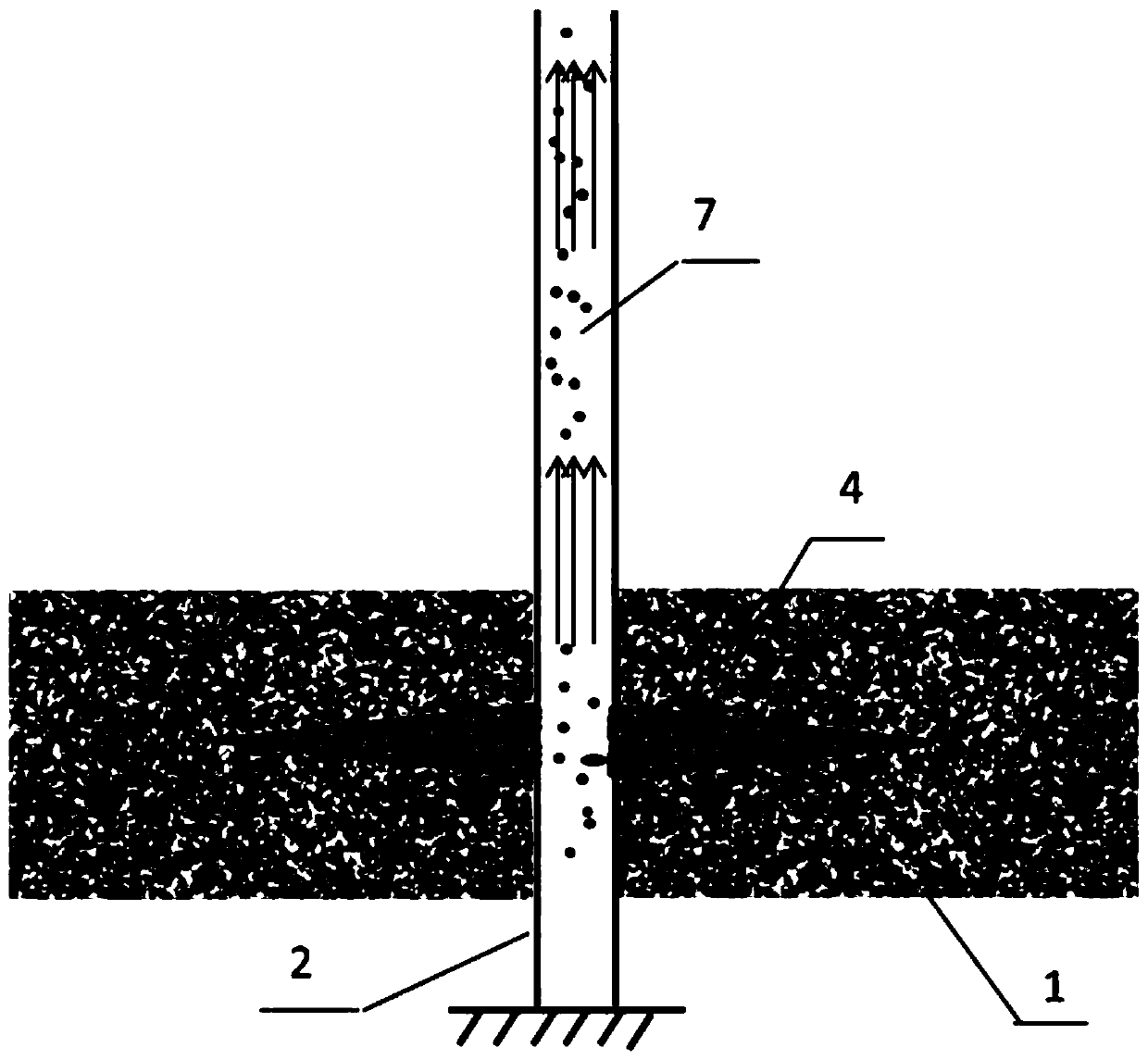

Method used

Image

Examples

Embodiment 1

[0055] A vertical well in the east area of Sulige, Changqing was reformed by the mechanical packer single-seal fracturing process. The well depth of the first layer of the target layer was 2500m, and the Φ73.0mm tubing single-seal fracturing string was used to inject plant starch, polymer, The expansion agent and the curing agent are composed according to the mass ratio of 6.5:4:0.5:3, and the density (normal temperature): 1.01g / cm 3 , stir to obtain the raw material mixture and make a rubber stopper, the construction steps are as follows:

[0056] Step 1: Perforating the target layer of the gas well with pressure through the casing;

[0057] Step 2: According to the well depth, select the prefabricated fracturing replacement isolator that starts to dissolve after reaching the depth of the fracturing layer at 60-90°C for 2 hours, and preset the rubber plug at the wellhead;

[0058] Step 3: Complete the pumping in the stages of low replacement, setting, pre-fluid, and sand-c...

Embodiment 2

[0062] A vertical well in the south area of Sulige, Changqing was refractured by mechanical packer staged fracturing technology. There were 2 target layers. Layer-by-layer fracturing reconstruction is carried out for each layer, and the composition of plant starch, polymer, expansion agent and curing agent is according to the mass ratio of 7.5:5:0.7:4, and the density (normal temperature): 1.21g / cm 3 , stir to obtain the raw material mixture and make a rubber stopper, the construction steps are as follows:

[0063] Step 1: Take out the perforating gun from the first layer and the second layer of the target layer of the perforated gas well through casing under pressure;

[0064] Step 2: According to the well depth, select one prefabricated fracturing replacement isolator that starts to dissolve after 4 hours at the depth of the fracturing layer at 90-120°C, and one prefabricated fracturing replacement isolator that starts to dissolve after 2 hours. The rubber plug is preset ...

Embodiment 3

[0071] A vertical well in the south area of Sulige, Changqing was refractured by mechanical packer staged fracturing technology. There were 2 target layers. Layer-by-layer fracturing reconstruction is carried out on each layer, and the composition of plant starch, polymer, expansion agent and curing agent is in a mass ratio of 8:6:0.8:5, and the density (normal temperature): 1.3g / cm 3 , stir to obtain the raw material mixture and make a rubber stopper, the construction steps are as follows:

[0072] Step 1: Take out the perforating gun from the first layer and the second layer of the target layer of the perforated gas well through casing under pressure;

[0073] Step 2: According to the well depth, select one prefabricated fracturing replacement isolator that starts to dissolve after 4 hours at the depth of the fracturing layer at 90-120°C, and one prefabricated fracturing replacement isolator that starts to dissolve after 2 hours. The rubber plug is preset at the wellhead;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com