Drilling machine for coal mine underground rail

A drilling machine, track technology, applied in the direction of boring/drilling, drilling/drilling equipment, components of boring machine/drilling machine, etc., can solve the problems of high labor intensity, high cost, increased volume, weight and cost, etc. , to achieve the effect of improving work efficiency, strong applicability and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

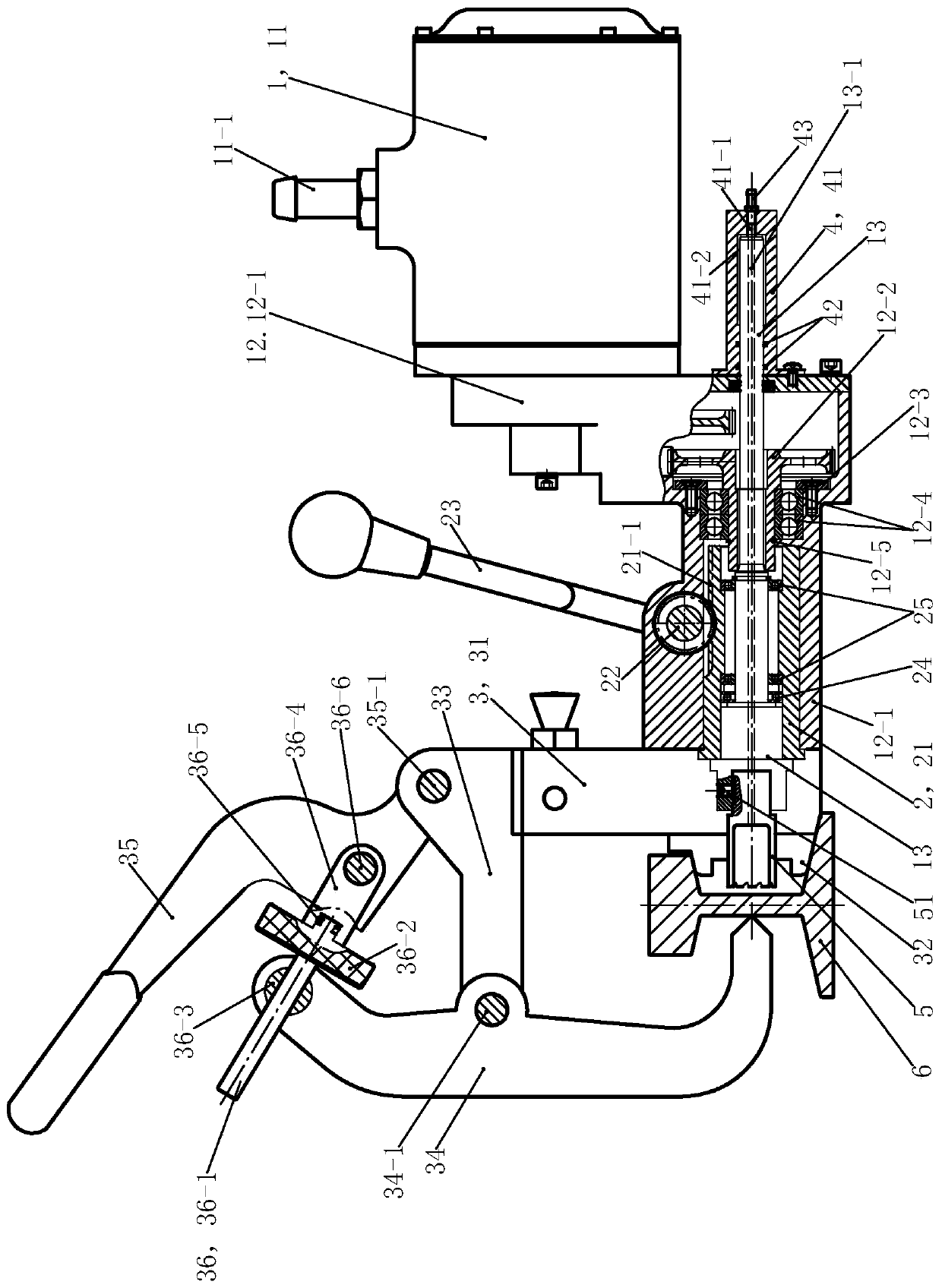

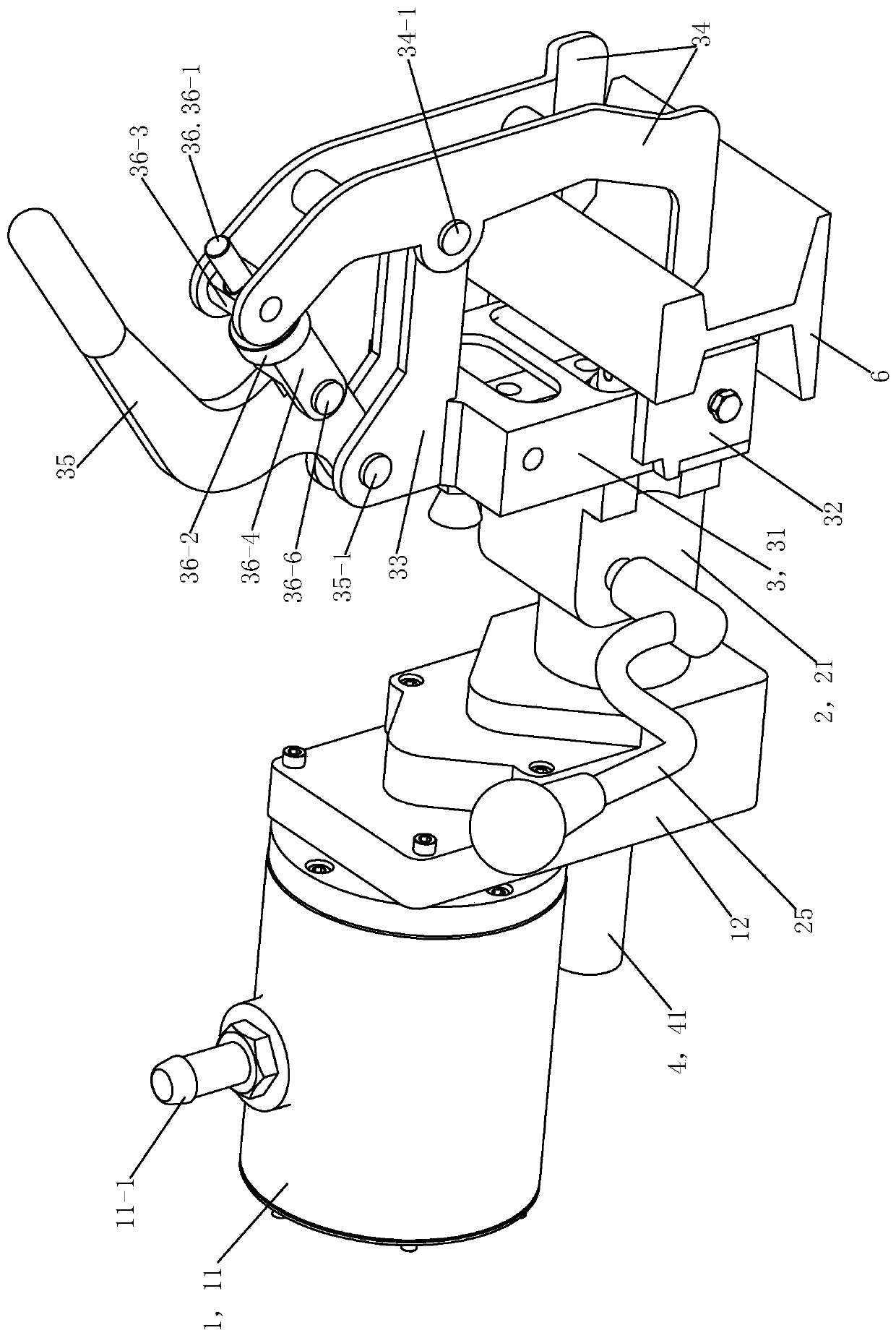

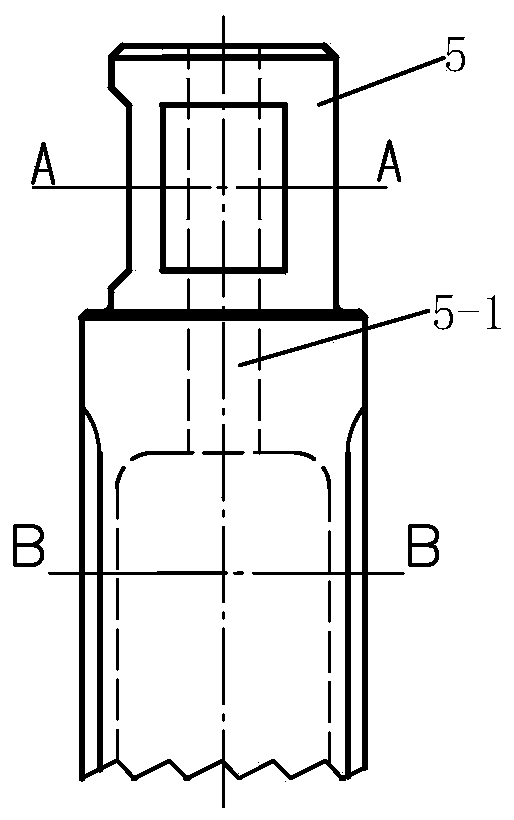

[0031] See figure 1 and figure 2 , The coal mine underground track drilling machine of this embodiment is mainly composed of a drive assembly 1, a feed assembly 2, a clamp assembly 3, a bushing assembly 4 and a drill bit 5.

[0032] The drive assembly 1 includes an air motor 11 , a reducer 12 and a transmission shaft 13 .

[0033] The air motor 11 is a commercially available product. The air motor 11 has an air inlet nozzle 11-1 and an output shaft. The air motor 11 can be a gear-type, vane-type or turbine-type air motor. The mouth 11-1 is connected to the existing compressed air in the coal mine as a power source through an air pipe to provide driving force. Reducer 12 has housing 12-1, input shaft and final stage gear 12-2, and reducer 12 is the reducer that is provided with two-stage reduction gear, and housing 12-1 is a hollow housing, and housing 12-1 It has integrally connected right and left parts, the input shaft and the two-stage reduction gear including the final...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com