Greenhouse seedbed mobile inspection robot

A robot and seedbed technology, which is applied in the field of robots, can solve the problems of hindered large-scale vegetable production, increased vegetable labor costs, and reduced vegetable production efficiency, so as to improve the work efficiency of seedling replenishment, increase the survival rate of seedlings, and reduce seedling damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

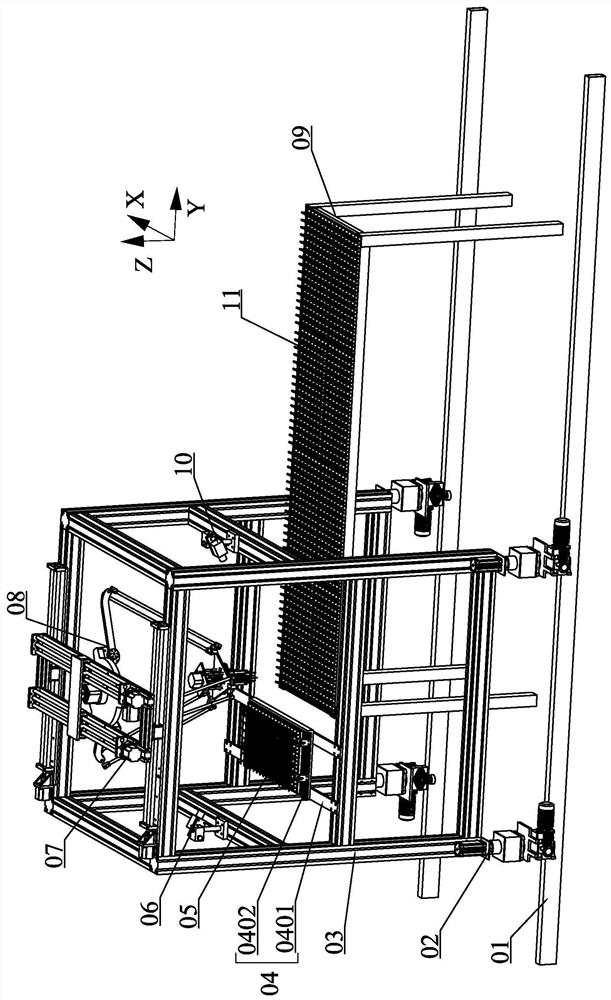

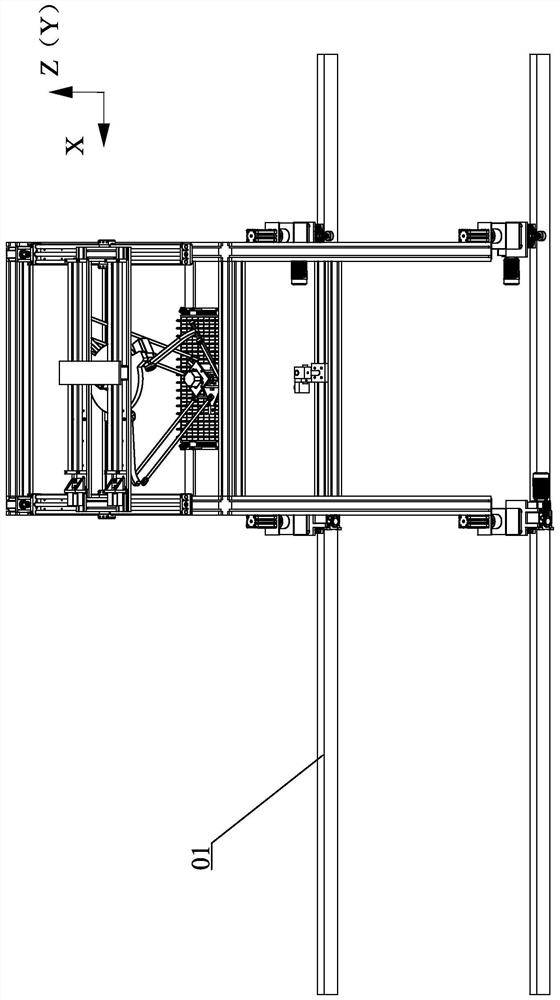

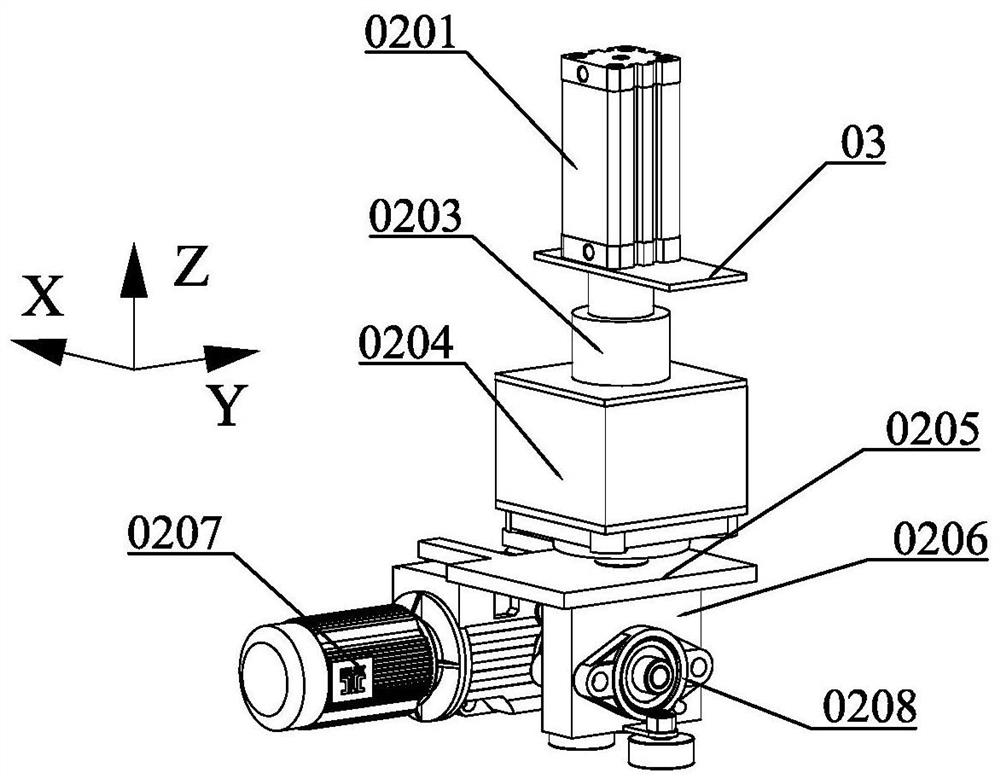

[0025] Further description will be given below in conjunction with the embodiments shown in the accompanying drawings.

[0026] For convenience of description, present embodiment adopts X, Y, Z coordinate system, and X-axis and Y-axis constitute horizontal plane (wherein the direction of Y-axis is the length direction of seedbed, i.e. figure 1 The left and right directions in the middle), the positive direction of the Z axis is perpendicular to the X-Y plane and goes up vertically.

[0027] Conventional vegetable seedling replenishment technology is to replace the seedling tray 05 on the seedling replenishment platform 04 ( Figure 9 Shown) the excellent seedlings are selected, and transplanted to replace the inferior seedlings to be replaced on the seedling tray 11 on the seedbed 09, thereby ensuring that all the seedlings on the seedbed are high-quality seedlings; due to the high labor intensity and low production efficiency of manual frequent operations, The invention deve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com