Laser Differential Confocal Precision Measurement Method of Spherical Inertial Elements with Gap

A differential confocal and fit gap technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problem of difficult accurate control of the fit gap of the ball bowl and spherical crown of inertial devices, so as to improve the accuracy and work reliability , Strong suppression characteristics, high focus precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

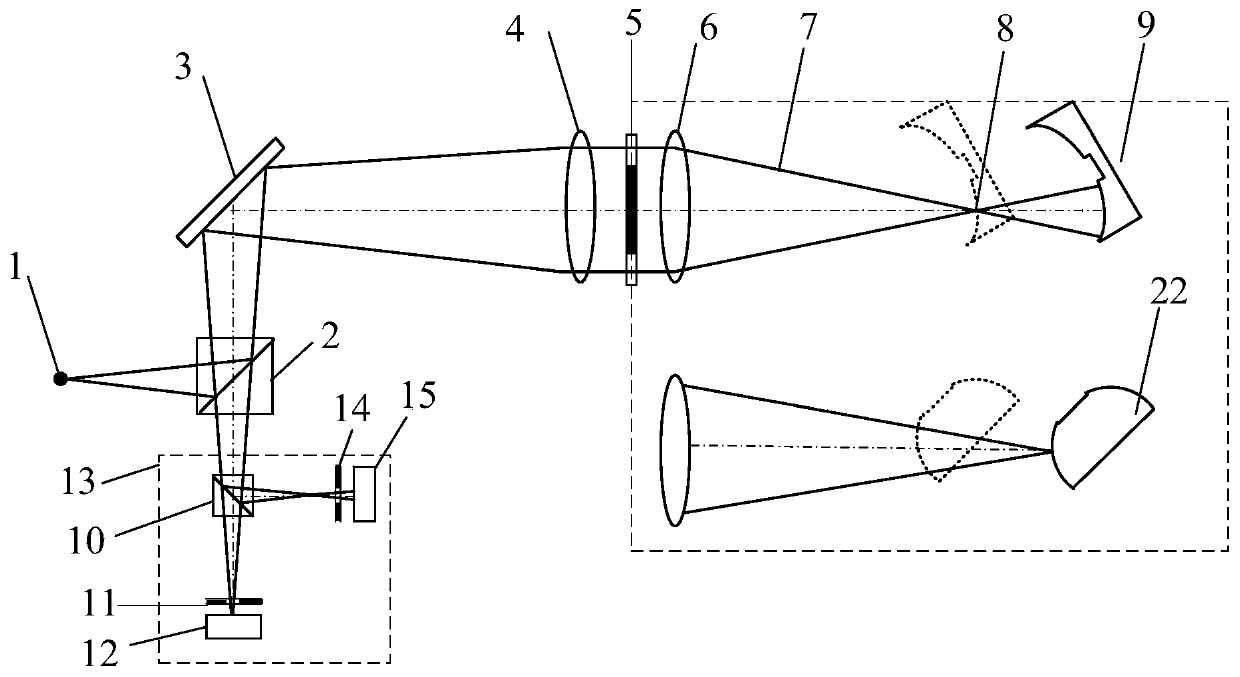

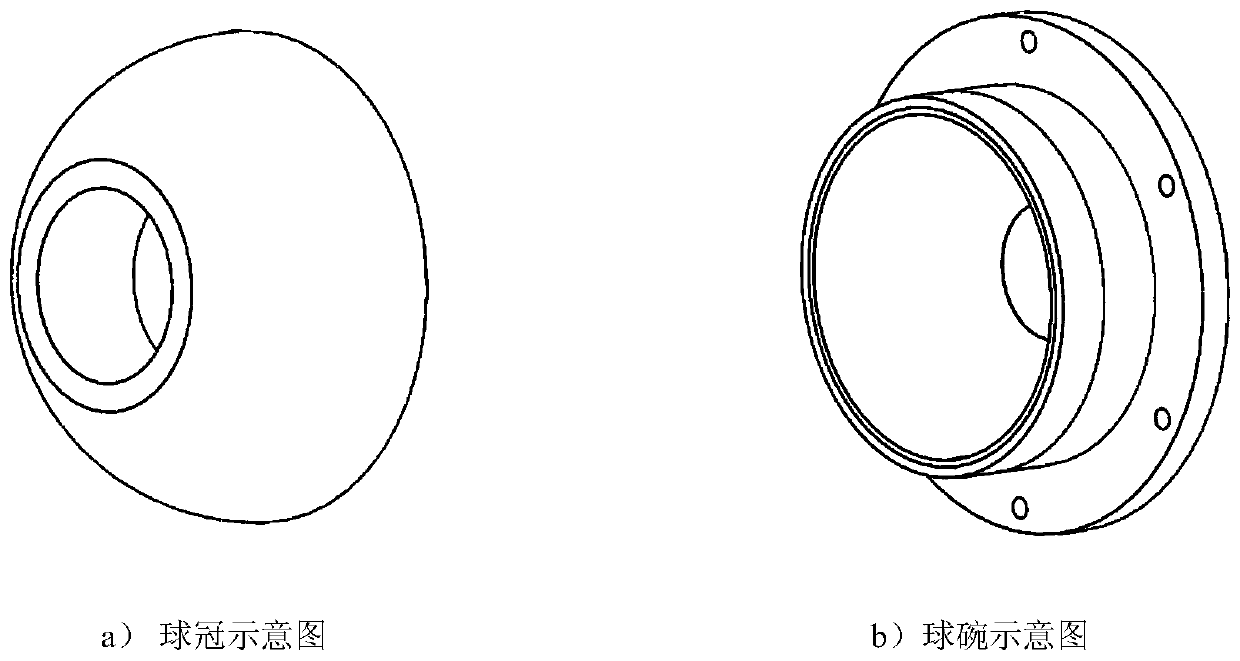

[0045] This embodiment is a schematic diagram of a ball bowl for a hemispherical dynamic pressure air bearing. image 3 -b) as an example to measure. Such as Figure 5 shown, based on figure 1 In the laser differential confocal inertial element curvature radius measurement method shown, the measurement steps are:

[0046] 1) Start the measurement software in the main control computer 18, turn on the laser 23, and the light emitted by the laser 23 is transmitted through the optical fiber 24 to form a point light source 1. The light emitted by the point light source 1 passes through the dichroic prism 2, the beam splitter 3, the collimating lens 4, the annular pupil 5, and the converging lens 6 to form a measuring beam;

[0047] 2) The ball bowl is fixed on the five-dimensional adjustment frame 25, the measuring beam is irradiated on the surface of the ball bowl to be measured, and the light reflected from the surface of the ball bowl passes through the converging lens 6 and ...

Embodiment 2

[0084] This embodiment is a schematic diagram of a spherical crown for a hemispherical dynamic pressure air bearing, as shown in image 3 -a) as an example to measure. Such as Figure 6 shown, based on figure 1 In the laser differential confocal inertial element curvature radius measurement method shown, the measurement steps are:

[0085] All the other steps are the same as the testing steps of the ball bowl in embodiment 1.

[0086] After repeated tests, the average value of the radius of curvature of the spherical crown was measured

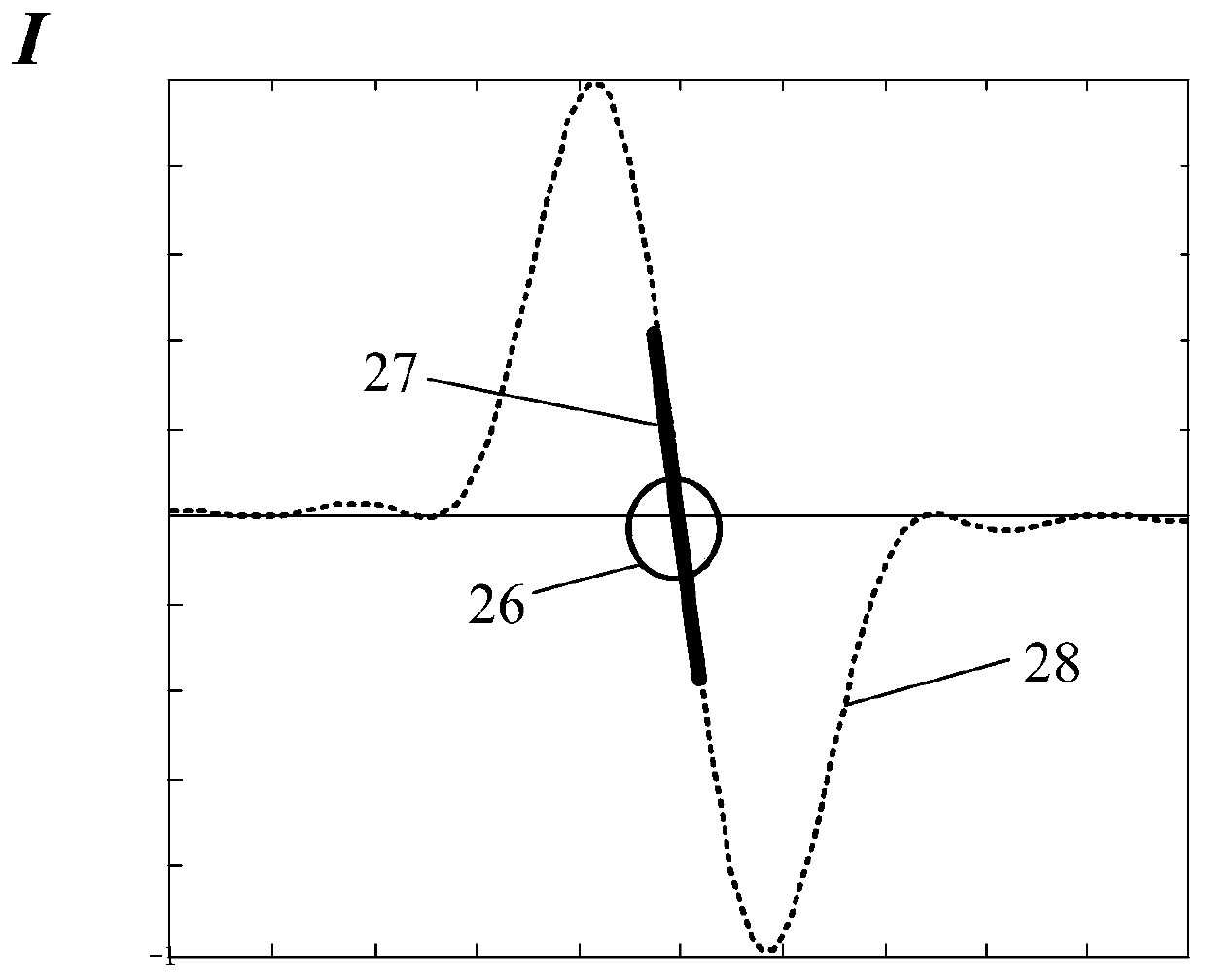

[0087] Then the fit gap between the ball crown and the ball bowl is as follows: Figure 4 Shown:

[0088]

[0089] Through repeated experiments and calculations, the clearance of the hemispherical dynamic pressure air bearing is 2.5 μm. The method can be used for random inspection and measurement of the curvature radii of various spherical crowns and spherical bowls on the production line of spherical parts of inertial devices, ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com