A method for preparing Shi's minerals based on ZVI reduction coupled microorganisms

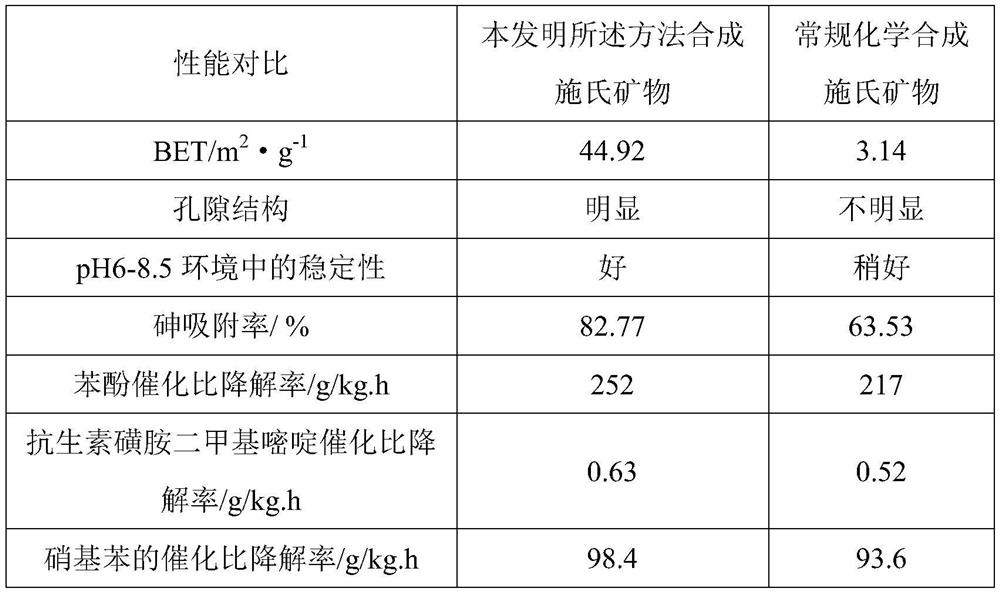

A technology of Shi's minerals and microorganisms, applied in the field of environmental engineering, can solve the problems of low amount of synthetic minerals in shake flask batches, low total iron precipitation rate, low iron precipitation rate and low synthetic minerals, and achieve the goal of avoiding a lot of manpower and material resources Effects of consumption, increase of mineral synthesis, and improvement of total iron precipitation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

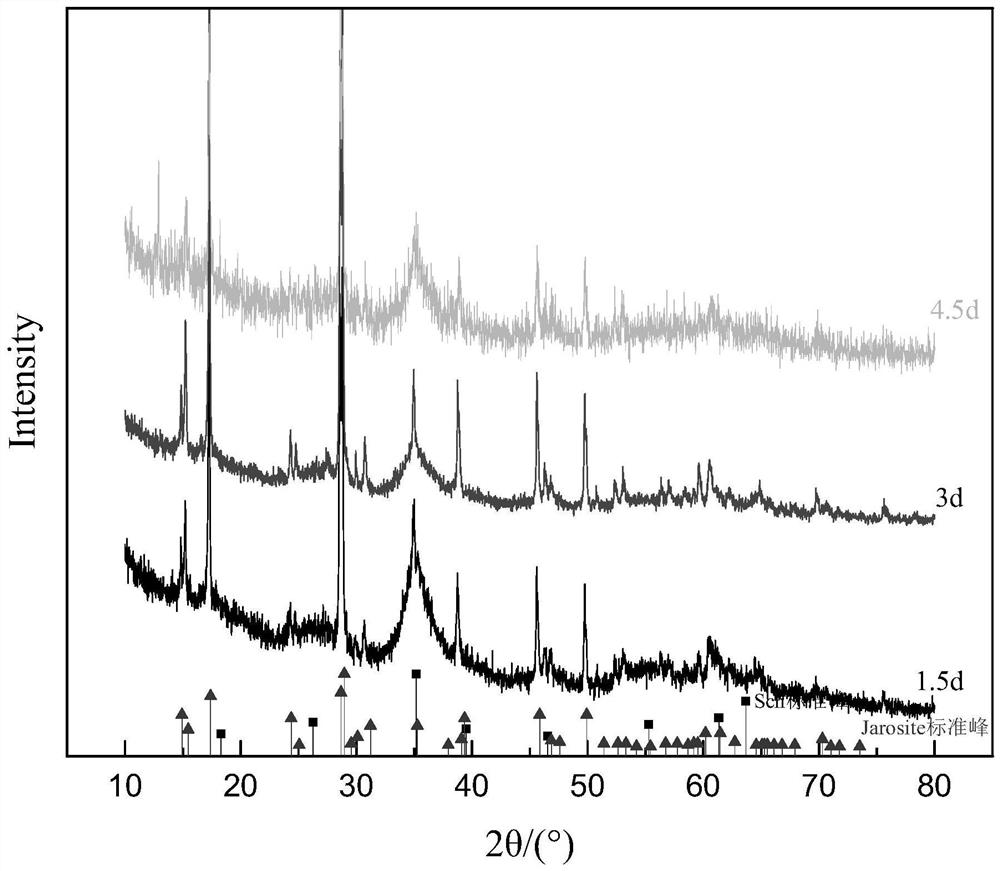

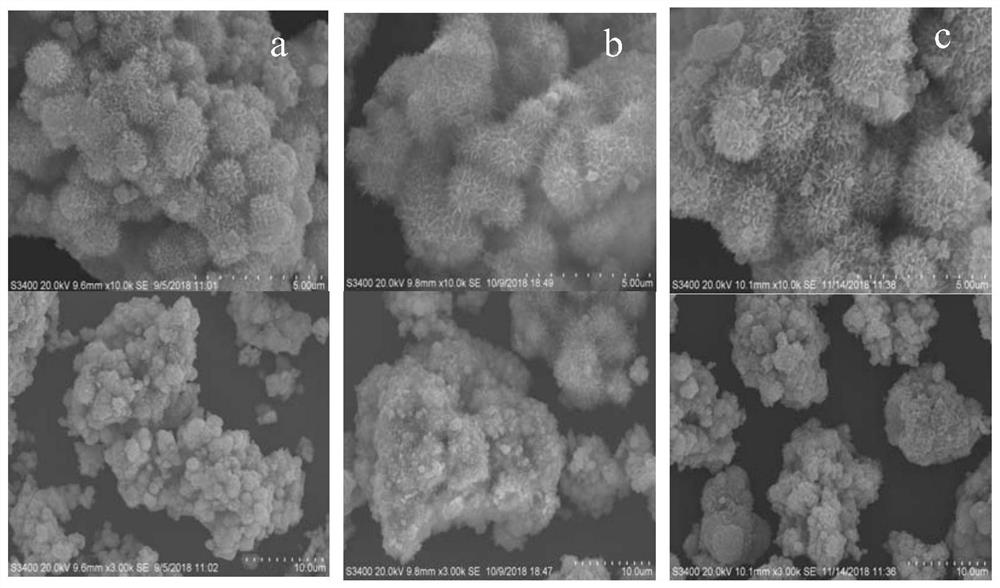

[0044] Prepare Shi's mineral under the condition of HRT=1.5 days:

[0045] The purchased A.ferrooxidans LX5 (Chinese patent: 02112924.X) was inoculated in the improved 9K medium (composition: (NH 4 ) 2 SO 4 3.5g / L, KCI 0.119g / L, K 2 HPO 4 0.058g / L (or K 2 HPO 4 ·3H 2 (00.076g / L), MgSO 4 ·7H 2 O 0.583g / L, Ca(NO 3 ) 2 4H 2 O 0.0168g / L, energy substance FeSO 4 ·7H 2 044.2g / L), use 1:1H 2 SO 4 Adjust the pH to 2.5, keep the total volume of the system at 3 L, place in a reciprocating shaker with a rotation speed of 180 r / min, and a temperature of 28° C. for 3 days. Place the bacterium solution after 3 days of expansion in container 1 (what this example adopts is a 3L beaker), add 22.24g / L FeSO 4 ·7H 2 0 and stir until it is completely dissolved, then continue to aerate and oxidize under the condition that the dissolved oxygen concentration is not lower than 6mg / L. When Fe in container 1 2+ After being fully oxidized by aeration, the mixed solution was continuou...

Embodiment 2

[0047] Prepare Shi's mineral under the condition of HRT=3 days:

[0048] A.ferrooxidans LX5 was inoculated in the improved 9K medium with 10% ratio (composition: (NH 4 ) 2 SO 4 3.5g / L, KCI 0.119g / L, K 2 HPO 4 0.058g / L (or K 2 HPO 4 ·3H 2 O 0.076g / L), MgSO 4 ·7H 2 O0.583g / L, Ca(NO 3 ) 2 4H 2 O 0.0168g / L, energy substance FeSO 4 ·7H 2 0 44.2g / L), with 1:1H 2 SO 4 Adjust the pH to 2.5, keep the total volume of the system at 3 L, place in a reciprocating shaker with a rotation speed of 180 r / min, and a temperature of 28° C. for 3 days. Place the bacterium solution after 3 days of expansion in container 1 (what this example adopts is a 3L beaker), add 22.24g / L FeSO 4 ·7H 2 0 and stir until it is completely dissolved, then continue to aerate and oxidize under the condition that the dissolved oxygen concentration is not lower than 6mg / L. When Fe in container 1 2+ After being fully oxidized by aeration, the mixed solution was continuously flowed into another contai...

Embodiment 3

[0050] Prepare Shi's mineral under the condition of HRT=4.5 days:

[0051] A.ferrooxidans LX5 was inoculated in the improved 9K medium with 10% ratio (composition: (NH 4 ) 2 SO 4 3.5g / L, KCI 0.119g / L, K 2 HPO 4 0.058g / L (or K 2 HPO 4 ·3H 2 O 0.076g / L), MgSO 4 ·7H 2 O0.583g / L, Ca(NO 3 ) 2 4H 2 O 0.0168g / L, energy substance FeSO 4 ·7H 2 0 44.2g / L), with 1:1H 2 SO 4 Adjust the pH to 2.5, keep the total volume of the system at 3 L, place in a reciprocating shaker with a rotation speed of 180 r / min, and a temperature of 28° C. for 3 days. Place the bacterial solution after 3 days of expansion into container 1, add 22.24g / L FeSO 4 ·7H 2 0 and stir until it is completely dissolved, then continue to aerate and oxidize under the condition that the dissolved oxygen concentration is not lower than 6mg / L. When Fe in container 1 2+ After being fully oxidized by aeration, the mixed solution was continuously flowed into another container 2 at a flow rate of 0.46mL / min, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com