A welding rod for brazing process

A brazing process and welding rod technology, which is applied in the field of automatic mold processing, can solve the problems of spending a lot of energy and cost, demanding raw material processing, and low mechanical properties of welds, so as to improve the performance of slag removal, promote the reduction of slag inclusions, Effect of improving anti-porosity performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

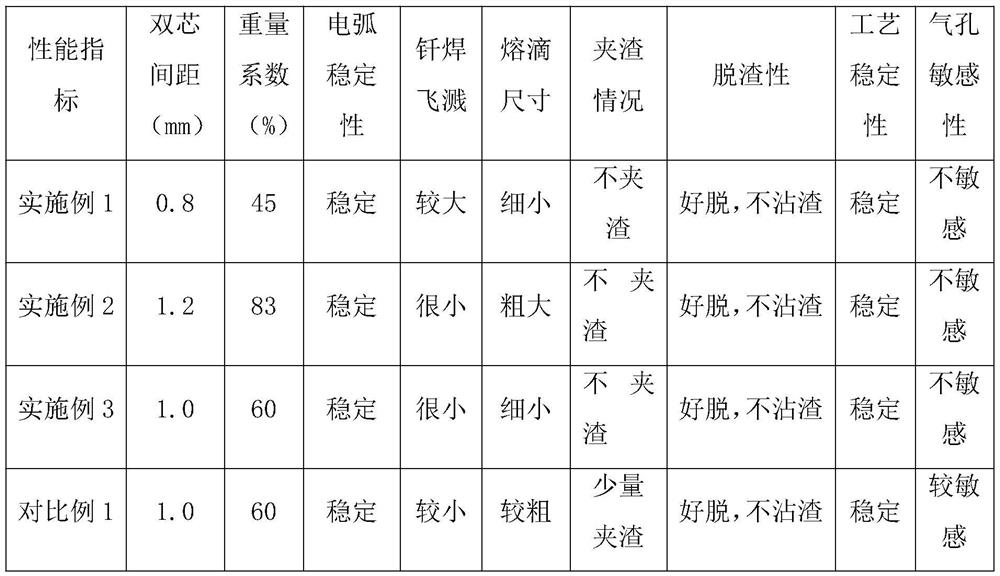

Embodiment 1

[0024] The present invention specifically provides a kind of welding rod used in the brazing process. Specifically, the implementation method of the preparation of the welding rod is as follows: the welding core components (weight fraction): C≦0.020%, Si≦0.050%, Mn0.40-0.60 %, S≦0.006%, P≦0.006%, Cr≦0.05%, Mo≦0.05%, Ni≦0.05%, Ti≦0.05%, Cu≦0.05%, As≦0.001% are refined into welding core in supporting steel plants , Derust the welding core with emery cloth, degrease with acetone, etc., and at the same time dispense the powder of the pharmaceutical coating component according to the requirements and composition of the powder formulation list. The coating composition and proportion are: marble: 100 parts, fluorite: 60 Parts, silicate: 10 parts, aluminum fluoride: 5 parts, multi-component alloy agent: 25 parts, stir and sieve the powder of the coating component, mix the various ingredients as evenly as possible, and then add an appropriate amount Soda water glass and potassium water...

Embodiment 2

[0031] The present invention specifically provides a welding rod for brazing process. Specifically, the preparation method of the welding rod is as follows: the welding core components: C≦0.020%, Si≦0.050%, Mn0.40-0.60%, S≦ 0.006%, P≦0.006%, Cr≦0.05%, Mo≦0.05%, Ni≦0.05%, Ti≦0.05%, Cu≦0.05%, As≦0.001%. Use emery cloth to remove rust, use acetone to remove oil, and at the same time, dispense the powder of the drug skin component according to the requirements and composition of the powder preparation list. The drug skin component and ratio are: marble: 100 parts, fluorite: 100 parts, silicic acid Salt: 15 parts, aluminum fluoride: 10 parts, multi-component alloy agent: 35 parts, stir and sieve the powder of the coating component to mix the various components as evenly as possible, and then add an appropriate amount of sodium silicate and potassium silicate to make paint. Put the paint into the double-deposited electrode coating press machine, press the electrode, and use it afte...

Embodiment 3

[0038]The present invention specifically provides a welding rod for brazing process. Specifically, the preparation method of the welding rod is as follows: the welding core components: C≦0.020%, Si≦0.050%, Mn0.40-0.60%, S≦ 0.006%, P≦0.006%, Cr≦0.05%, Mo≦0.05%, Ni≦0.05%, Ti≦0.05%, Cu≦0.05%, As≦0.001%. Use emery cloth to remove rust, use acetone to remove oil, and at the same time dispense the powder of the drug skin component according to the requirements and composition of the powder preparation list. The drug skin component and ratio are: marble: 100 parts, fluorite: 80 parts, silicic acid Salt: 12 parts, aluminum fluoride: 8 parts, multi-component alloy agent: 30 parts, stir and sieve the powder of the drug coating component to mix the various components as evenly as possible, and then add an appropriate amount of sodium silicate and potassium silicate to make paint. Put the paint into the double-deposited electrode coating press machine, press the electrode, and use it aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com