Improved test method for determining crack resistance of concrete under condition of restrained shrinkage

A technology of anti-cracking performance and test method, applied in the direction of material inspection products, etc., can solve the problems of unrealized anti-cracking performance of concrete materials at an early age, the effect of shrinkage cracking restraint is not obvious, and testing, etc. Shorten, reduce test costs, eliminate the effect of driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

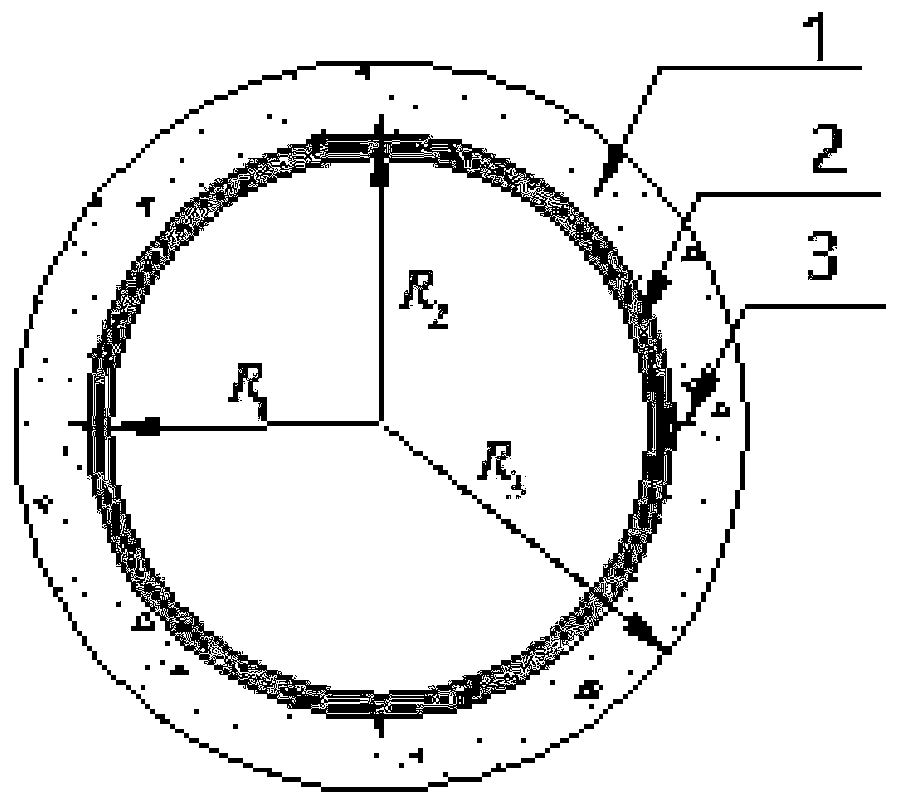

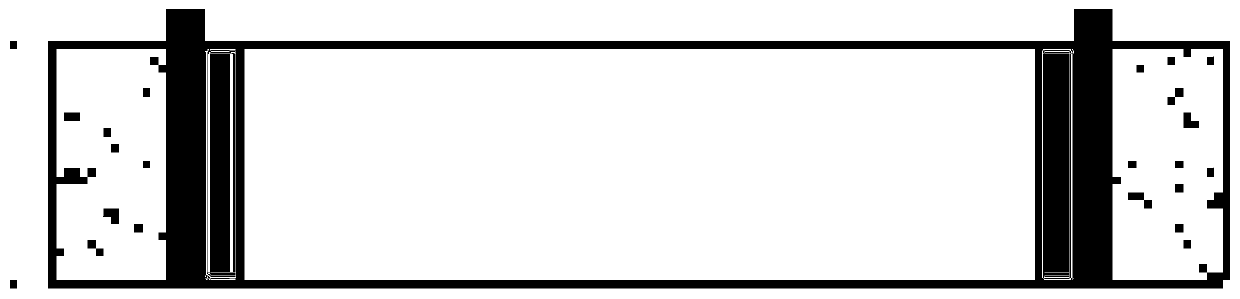

[0014] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0015] (1) Test preparation

[0016] Inner diameter R of steel ring 2 1 137.5mm, outer diameter R 2 150mm, thickness R 2 -R 1 =12.5mm, the height is 75mm. The prefabricated crack is made of steel, with a height of 85 mm and a cross-section of an isosceles triangle with a base of 3 mm and a height of 6 mm, see Figure 1(c). Before the experiment, use 502 glue to evenly paste 4 prefabricated cracks on the surface of the outer ring of the steel ring 2 at intervals of 90°. The bottom of the prefabricated cracks is flush with the bottom of the test piece, and the top is 10 mm higher than the test piece. For details, see attached drawing 1 (a ), (b).

[0017] (2) Test piece production

[0018] C30 concrete with a water-cement ratio of 0.5 was used to pour the constrained ring-shaped specimen. After pouring,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com