Integrated type dual-cavity radiator sealing structure

A sealed structure, integrated technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., to achieve the effect of reducing power consumption, reducing the risk of thermal fatigue failure, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

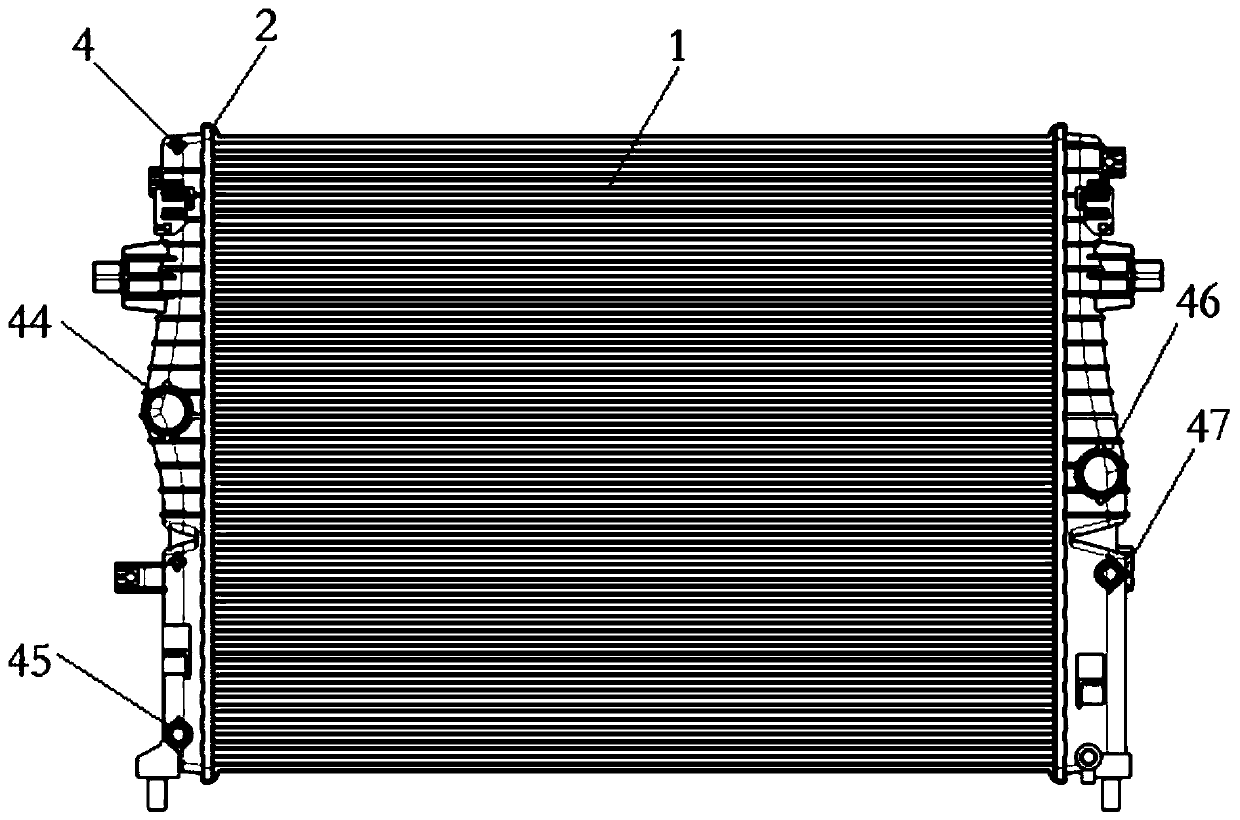

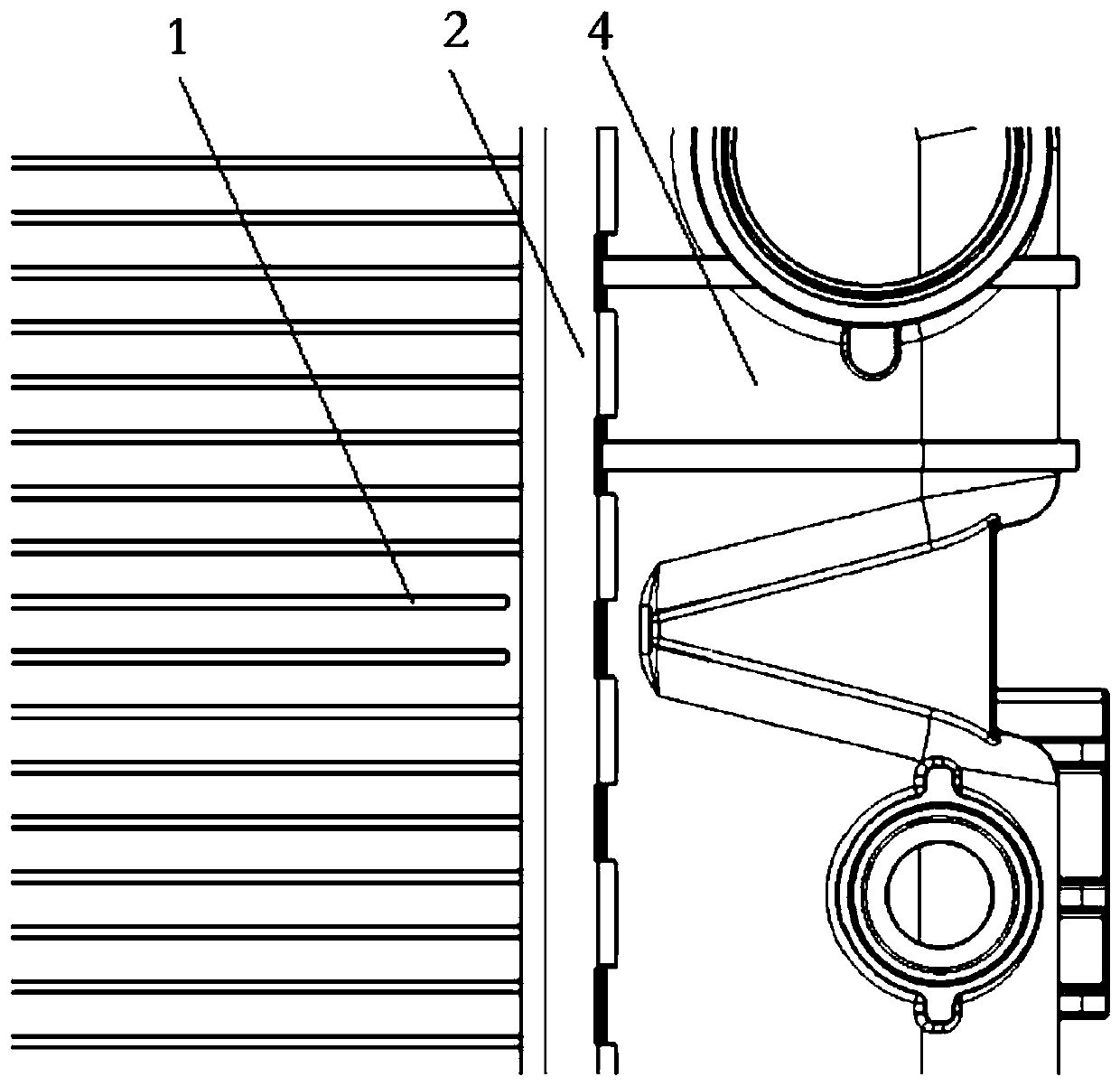

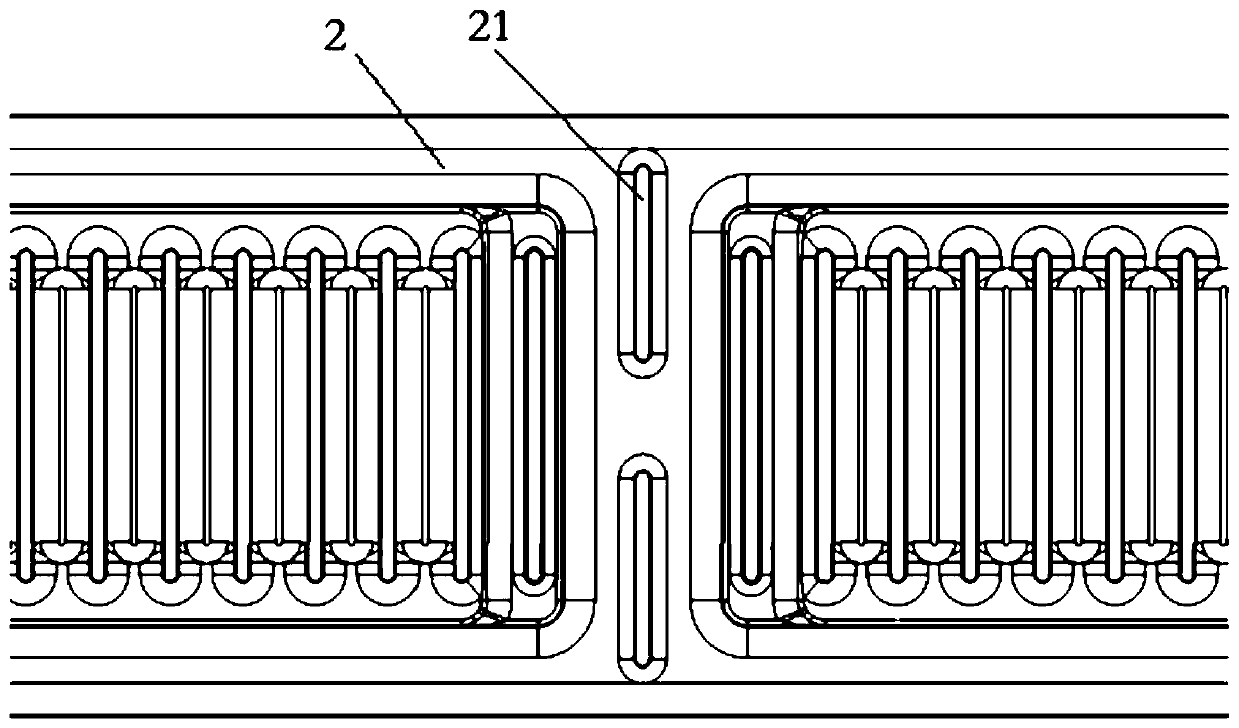

[0023] Such as Figure 1-8 As shown, the integrated double-chamber radiator sealing structure provided in this embodiment includes a flat tube 1, a main piece 2, a rubber strip 3 and a water chamber 4, and the water chamber is divided into an upper chamber 42 and a lower chamber by a partition 41 43. In this way, the radiator can be divided into two separate upper and lower cooling regions, that is, the upper cavity 42 and the lower cavity 43 of the water chamber 4 on one side of the flat tube 1 are respectively provided with a high temperature zone inlet 44 and a low temperature zone inlet 45 , the upper cavity and the lower cavity of the water chamber on the other sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com