House building with fabricated frame structure

A frame structure and prefabricated technology, applied in buildings, protected buildings/shelters, building components, etc., can solve the problems of complex building structure, inconvenient construction, etc., to prevent displacement, low manufacturing cost, and ensure construction The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

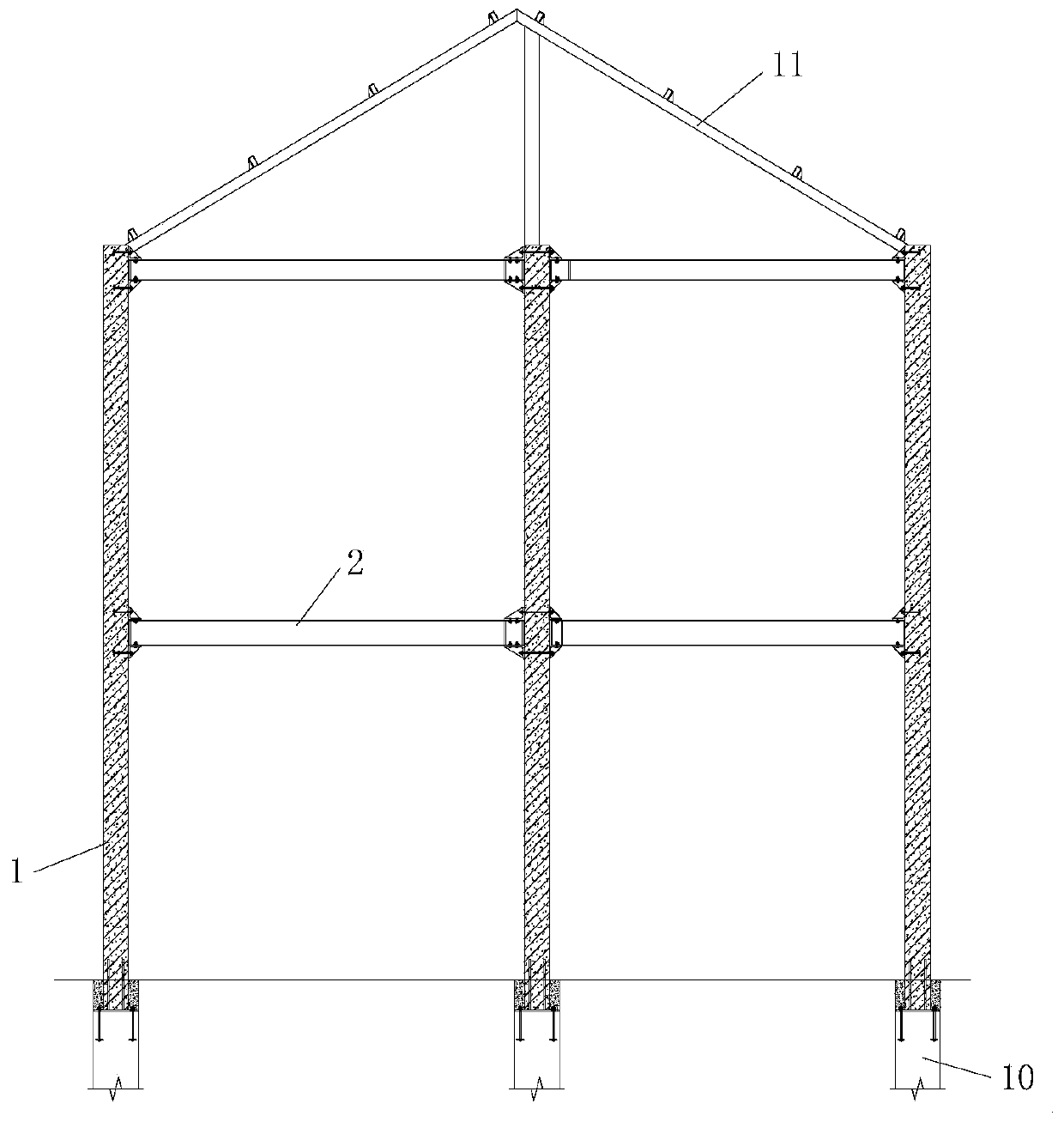

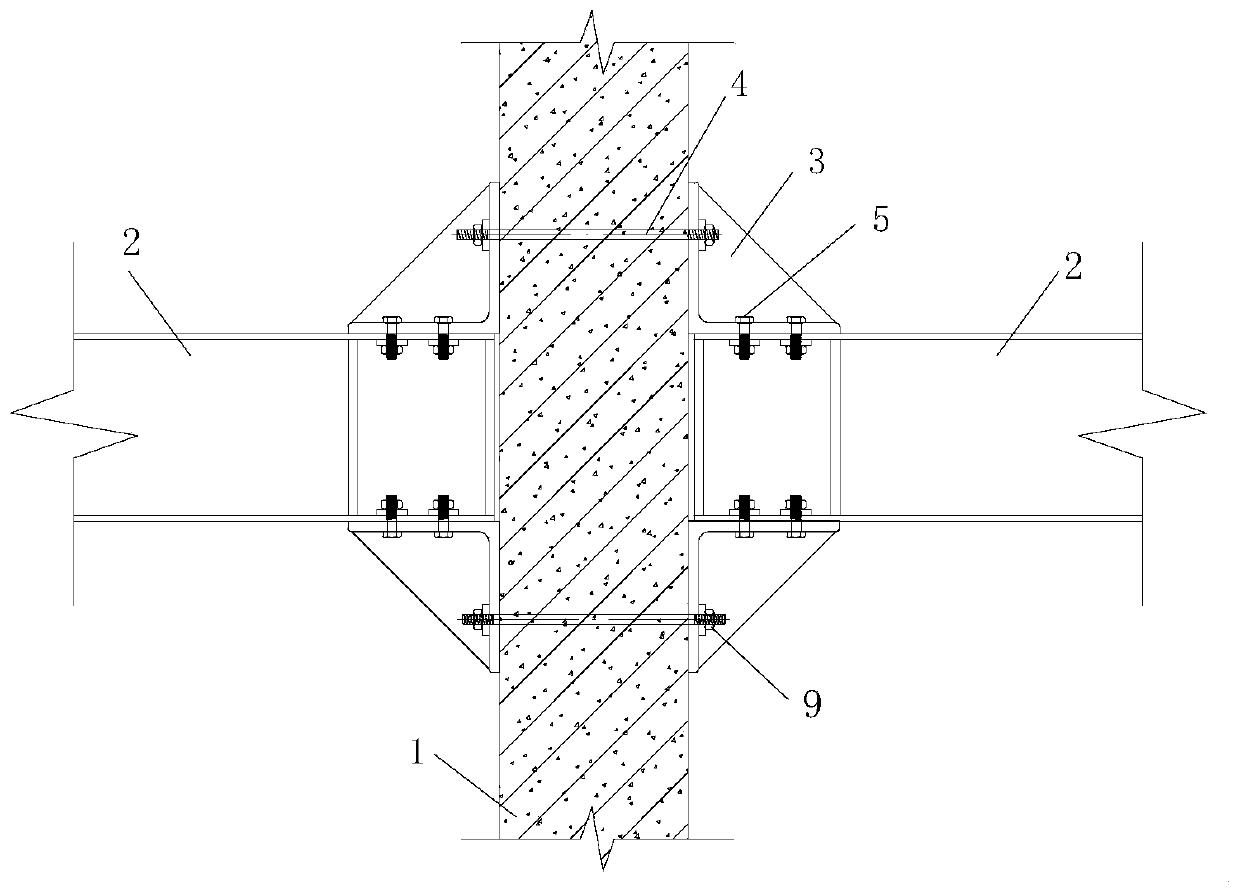

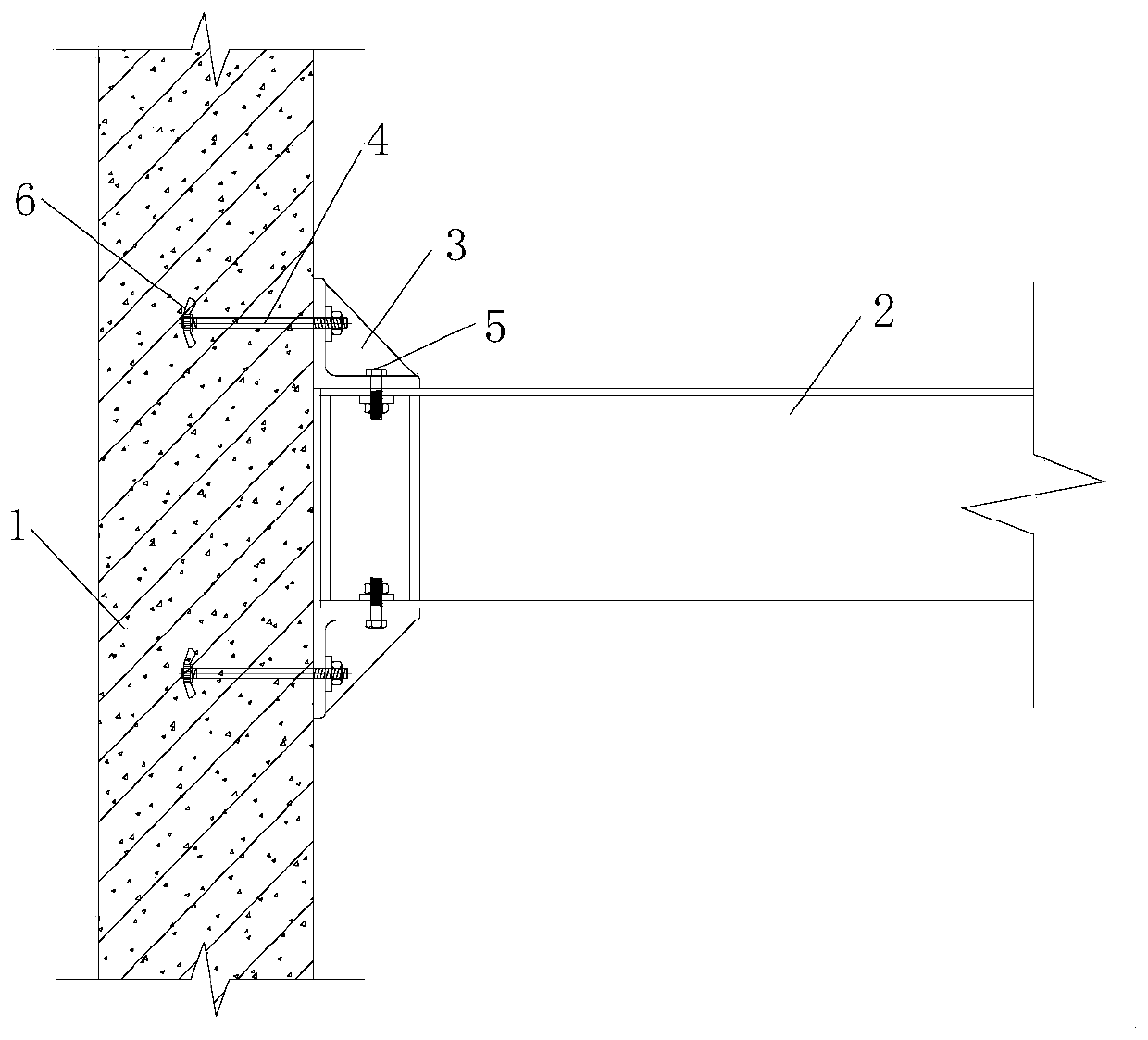

[0034] Such as Figure 1 to Figure 5 , a prefabricated frame structure building of the present invention, comprising a prefabricated column 1 fixed vertically on the foundation 10 of the frame structure building, a steel beam 2 vertically connected to the prefabricated column, and at least one piece of steel beam located above and below the steel beam. Corner code 3, wall panels and roof panels, the prefabricated column includes at least one set of horizontally preset tension bolts 4, the steel beam 2 is H-shaped steel and / or I-beam, and the corner code includes the first vertical connection plate and the second connecting plate, the first connecting plate and the second connecting plate are arranged close to the prefabricated column and the steel beam res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com