Automatic storing and sorting system of mobile robot

A mobile robot, automatic storage technology, applied in storage devices, transportation and packaging, etc., can solve the problem of not meeting the needs of users to select the number of SKUs and storage space, to improve the maximum utilization rate, increase the scope of picking work, and improve the picking operation. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

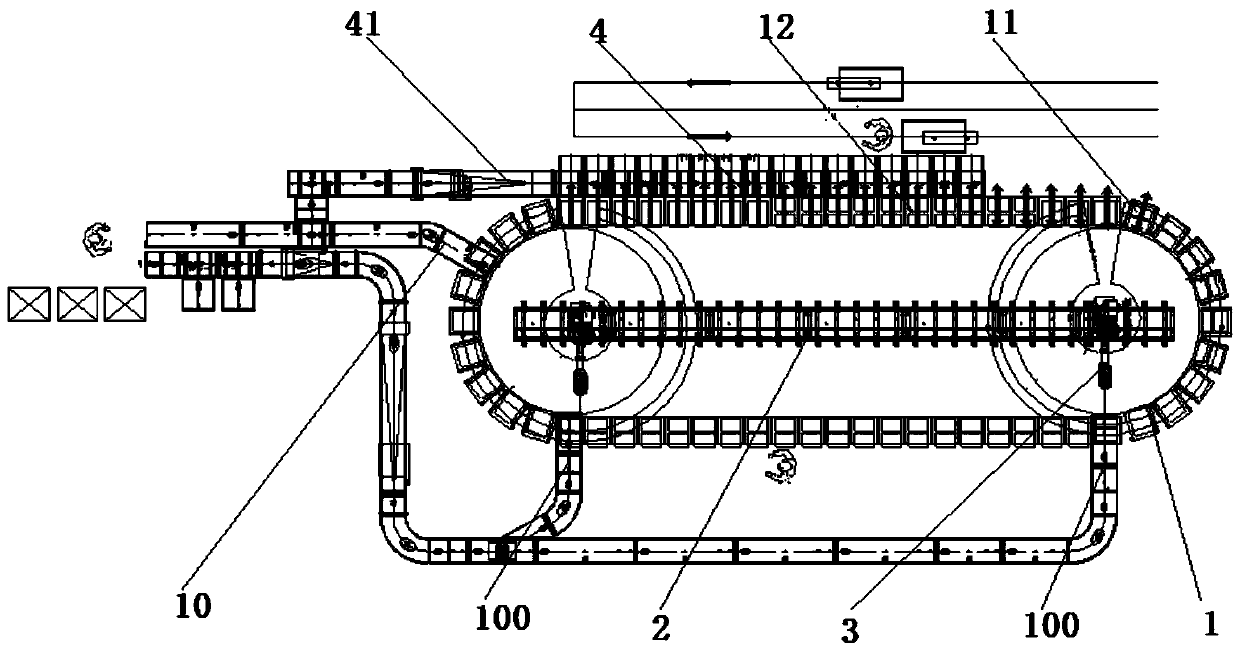

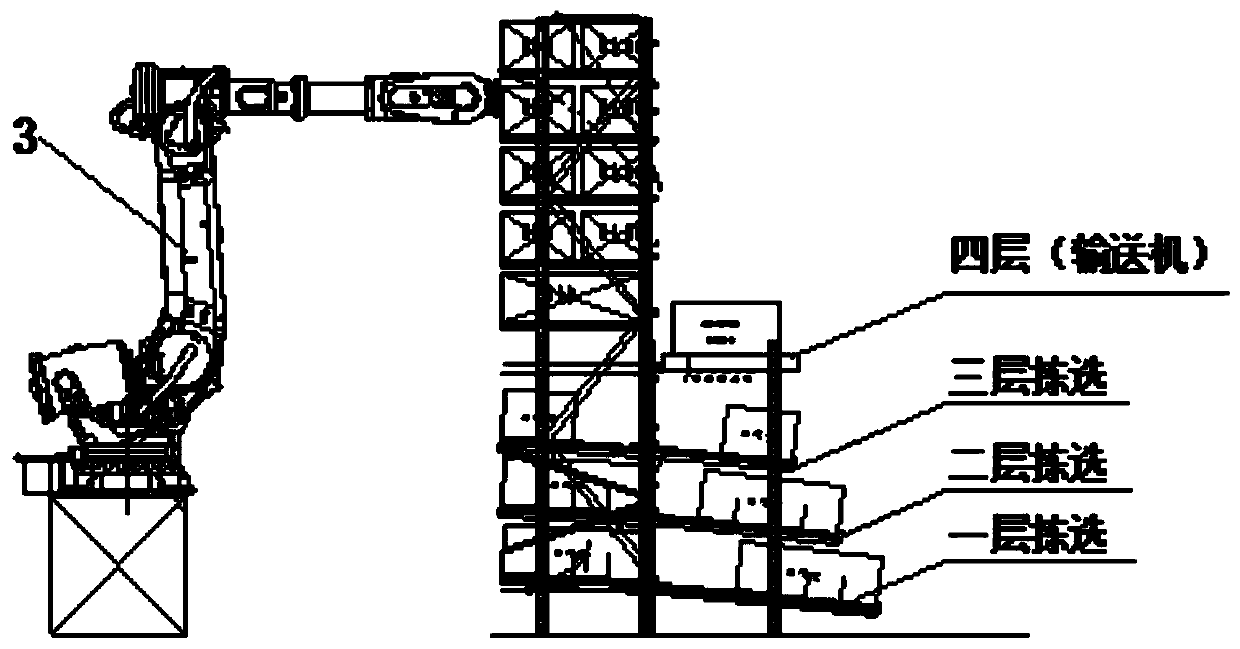

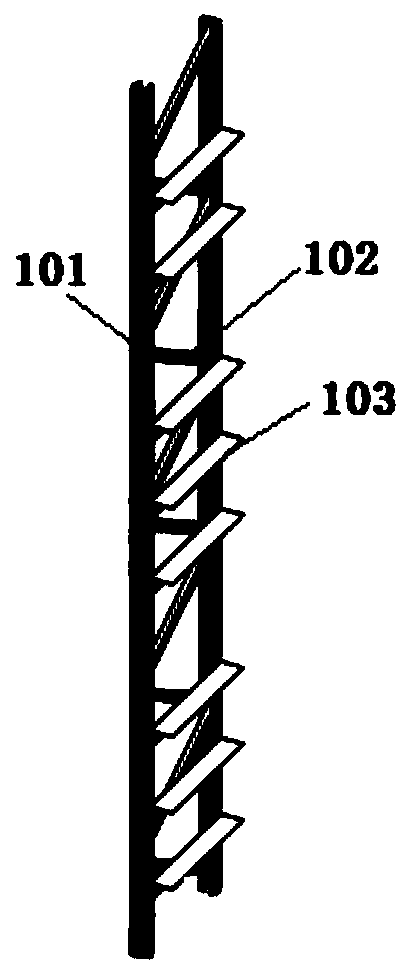

[0021] refer to figure 1 The present invention is an automatic storage and picking system for a mobile robot, comprising an annular shelf 1, a robot track 2, a robot 3, and a manual picking station 4. The robot track 2 is arranged inside a closed area surrounded by the annular shelf 1. The robot The base of 3 is equipped with walking wheels matched with robot track 2, a drive motor that controls robot 3 to move along the track of robot track 2, and said robot track 2 is provided with at least one movable robot 3, and said manual picking worker The station 4 is located on one side outside the enclosed area surrounded by the ring shelf 1, and the work area shelf of the manual picking station 4 is arranged along the track direction of the robot track 2. Described annular shelf 1 comprises the semi-annular shelf 11 that is arranged oppositely at two ends of robot track 2 and the linear shelf 12 that is symmetrically arranged on both sides of robot track 2, and the two ends of desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com