Alternated sealing machine

A sealing machine, an alternate technology, applied in the field of packaging bag sealing, can solve the problems of a lot of wasted time and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

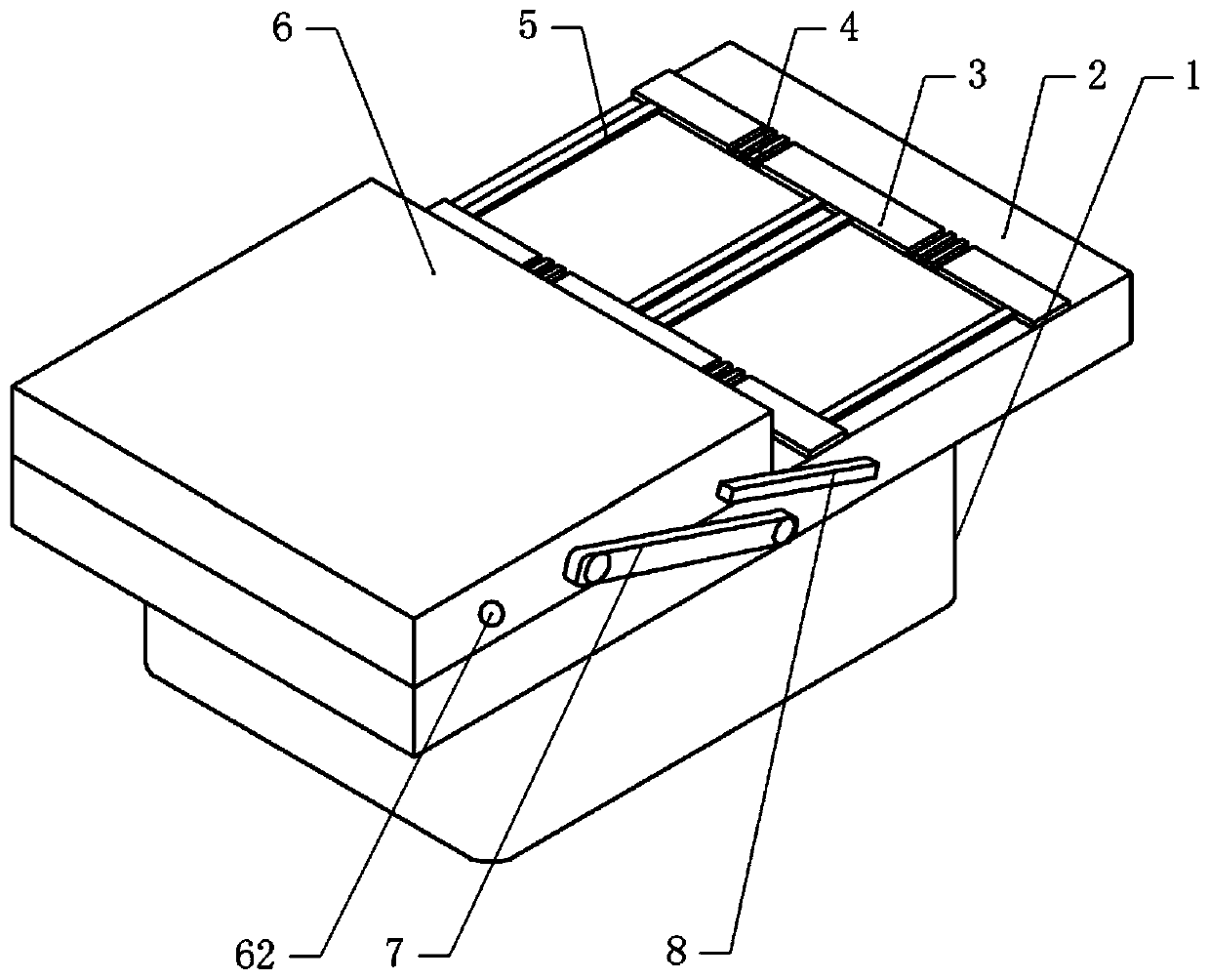

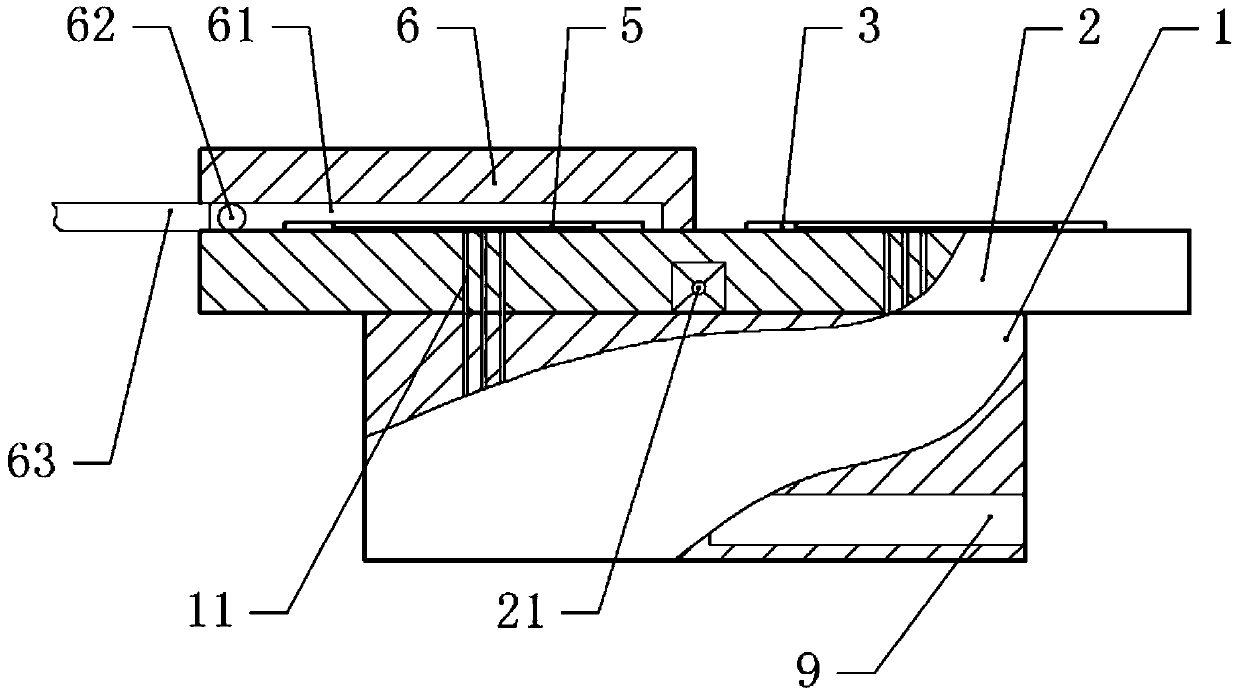

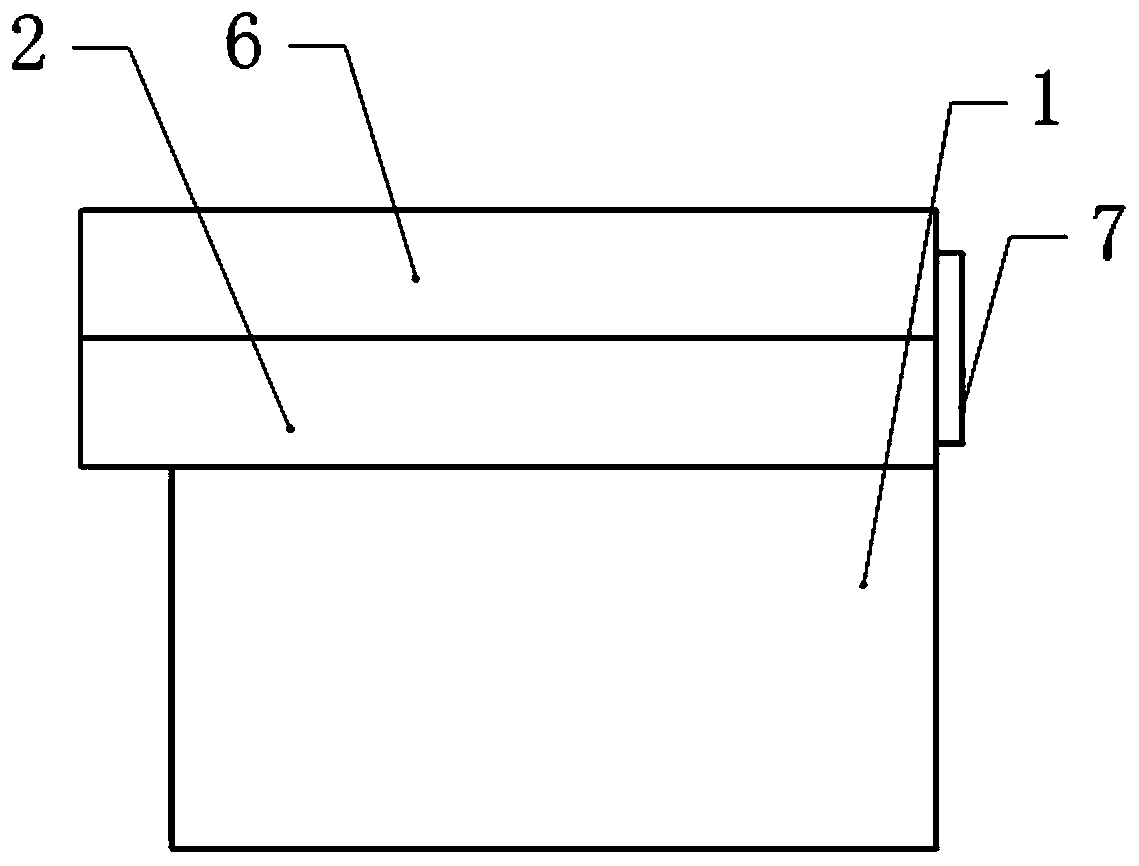

[0028] An alternate sealing machine, as attached figure 1 As shown, a support platform 1 and a workbench 2 fixed on the support platform 1 are included. The cross section of the supporting platform 1 is square, and the cross section of the workbench 2 is rectangular.

[0029] The left and right sides of the workbench 2 are provided with several fixing parts. In this embodiment, there are two fixing parts and the two are parallel, and the fixing parts in this embodiment are metal strips 3 made of iron materials, and the metal strips 3 are welded. On the upper end face of the workbench 2. Metal strips 3 are provided with several groove units. In this embodiment, there are two groove units on each metal strip 3. The groove units include limit strips and some grooves 4. In this embodiment, the grooves 4 is three, and the limit bar is made of copper material, and both the limit bar and the groove 4 can be detachably connected. Specifically: insert the two ends of a limit bar int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com