Shipment and sorting system

A sorting system and sorting port technology, applied in sorting and other directions, can solve the problems of high investment in equipment and personnel, many errors, and high labor intensity, and achieve the goals of reducing equipment investment, controlling error rate, and improving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

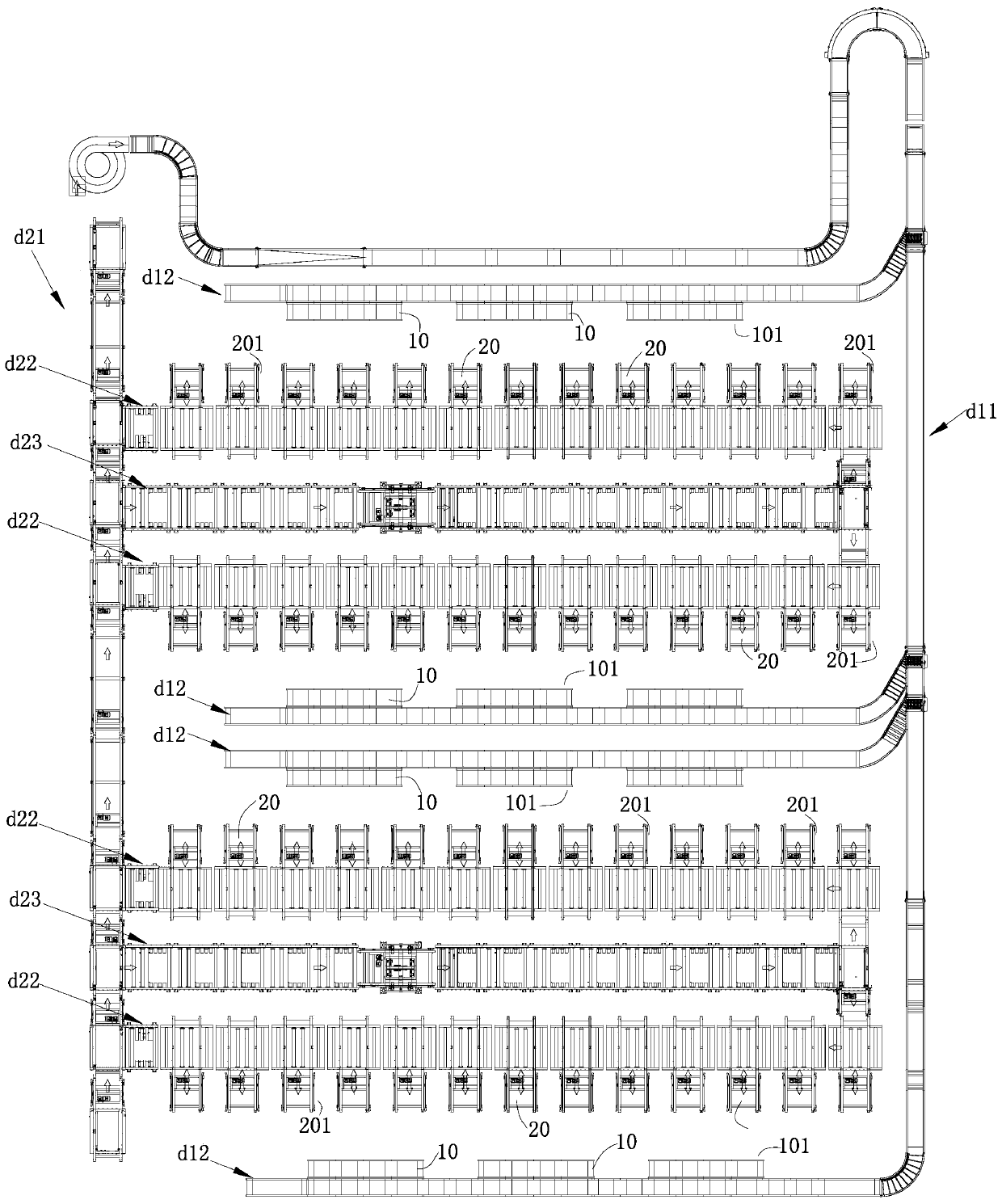

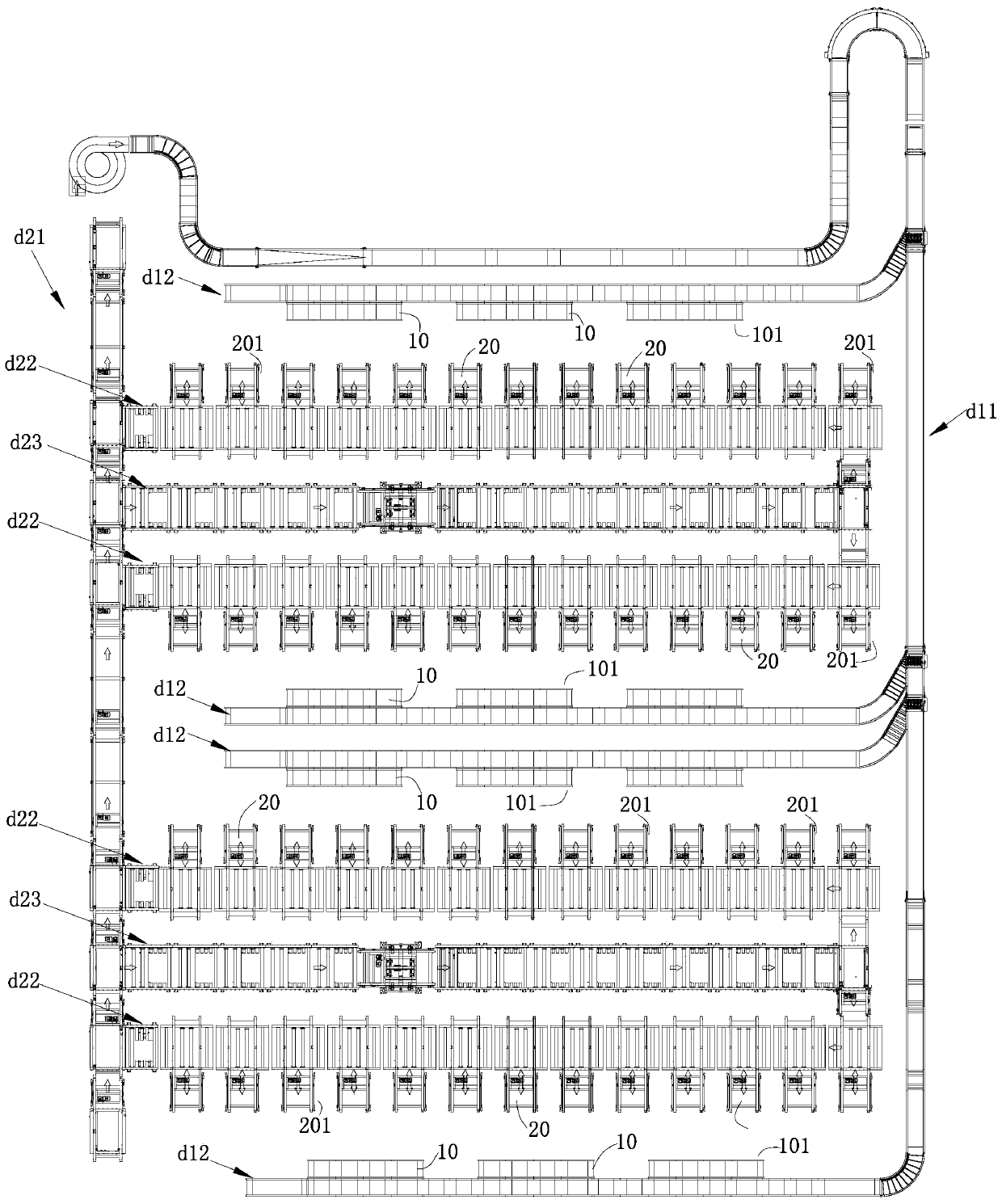

[0023] Such as figure 1 As shown, a sorting system for shipments, the sorting system includes a plurality of sorting ports 10, a plurality of stacking ports 20, a supply roller table communicated with a plurality of sorting ports 10, and a plurality of stacking ports 20 communicated Outgoing roller table, control system, the supplying roller table has a goods receiving end, and the outbound roller table has a goods outlet end and a pallet inlet end respectively located on both sides, and the sorting system also includes a stack connected to the outbound roller table. Board replenishment roller table d23, each sorting port 10 is set in correspondence with multiple stacking ports 20, the sorting system also includes a function for detecting the properties of the goods and instructing the operator to move the goods at the sorting port 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com