Multi-channel automatic ball adding device for ball milling machine

A multi-channel, ball mill technology, applied in the field of mining equipment, can solve the problems of inability to measure the number of balls added, inaccurate number of balls added, and single type of balls added, so as to improve ergonomics, high work efficiency, and realize cost reduction and increase effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

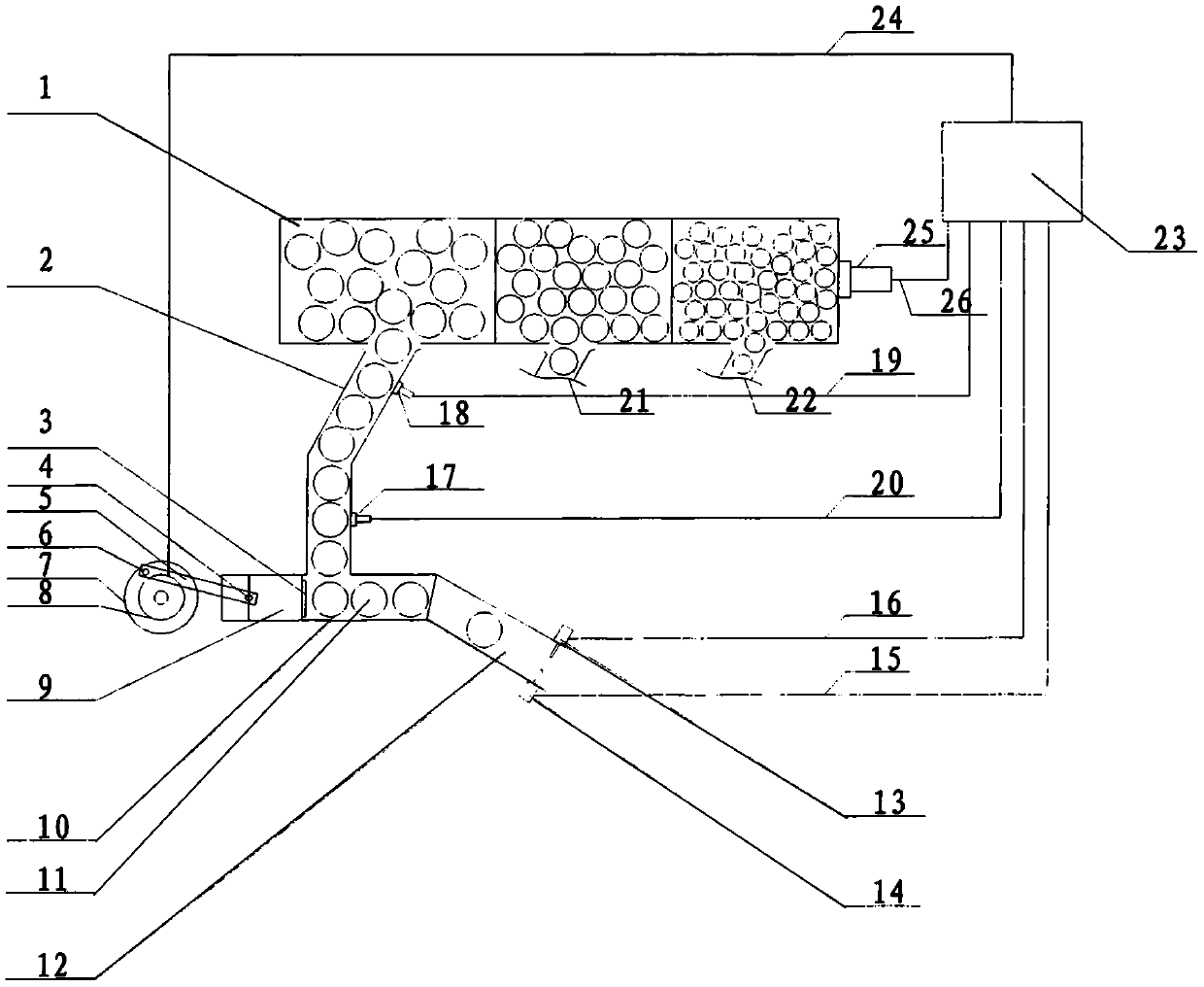

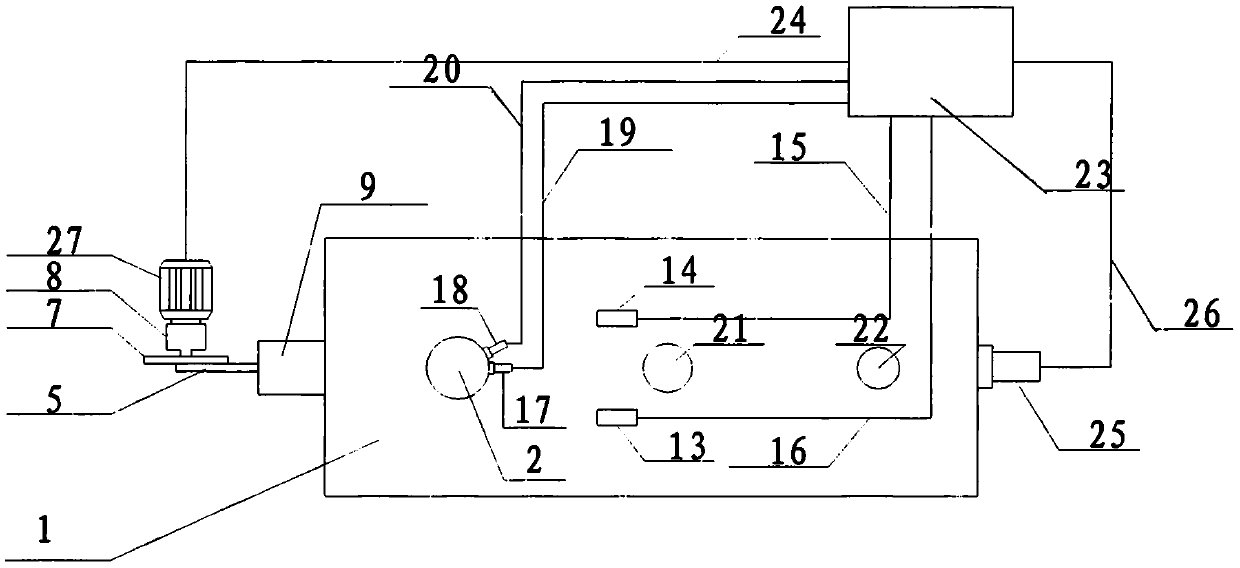

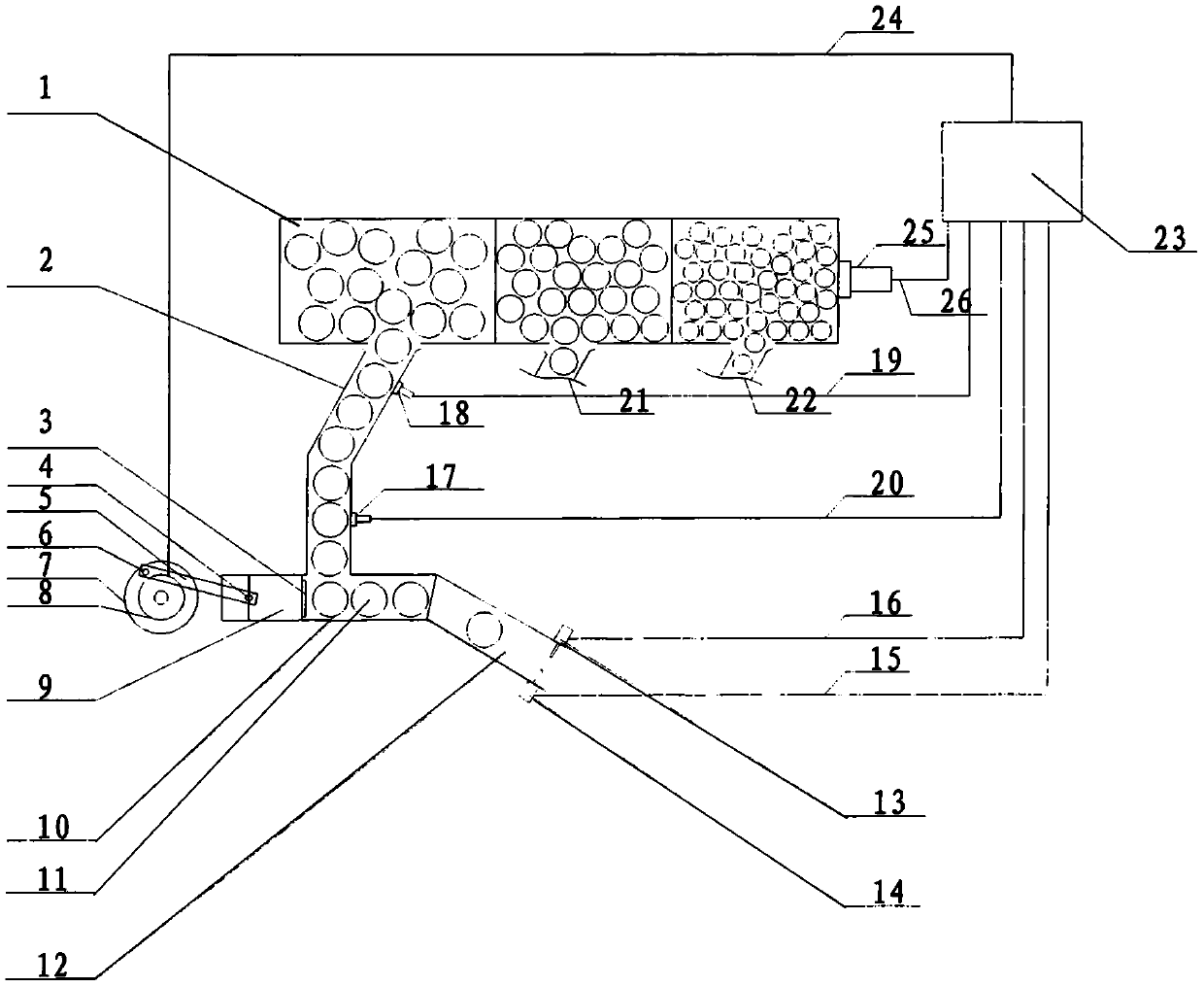

[0020] as attached figure 1 figure 2 A multi-channel automatic ball adding device for a ball mill is shown, including a vibrating ball storage bin 1, a U-shaped groove 10, a piston 9, a connecting rod 5, an eccentric disc 7, a photoelectric sensor A, a photoelectric sensor B, a travel switch A13, and a travel switch B14, control box 23, motor 27 and speed reducer 8; The described vibration storage ball storehouse 1 is arranged on the top of the device, the vibration storage ball storehouse 1 top is a cuboid structure, and the vibration storage ball storehouse top is a cuboid structure without a cover, and the side has The vibrating motor, the top of the ball storage bin is open, the interior is hollow, and the bottom is provided with lower ball holes of various specifications, and the bottom of the lower ball holes is provided with inclined guide t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com