A graph-based detection method for flow pulsation characteristics of multi-pump confluence

A flow pulsation and detection method technology, applied in the direction of measuring devices, measuring rapid changes, instruments, etc., can solve the problems of high cost, low efficiency, and inability to provide theoretical basis for multi-pump system design and development, and achieve simple calculation and satisfactory calculation accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

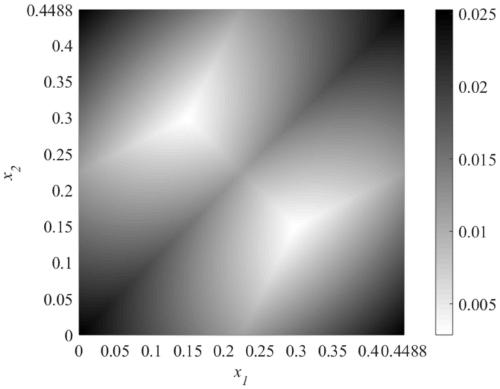

[0052] This embodiment provides a method for detecting the pulsation characteristics of the confluent flow of a three-way pump. The main steps of the method are shown in Fig. figure 1 shown.

[0053] In this example, the three pumps are all plunger pumps with 7 plungers. When each pump works independently, its geometric flow function is The instantaneous flow function is a periodic function with a period of β, and the period of the combined flow function is still β. The average flow is 2K sin(β / 2) / β. K is a coefficient related to the structure and speed of the plunger pump itself, K=ωπd 2 R tan α / (8 sinβ / 2), ω is the speed of the pump, d is the diameter of the plunger, R is the radius of the distribution circle where the plunger axis is located, and β is half of the angle between two adjacent plungers, that is, β=π / Z, Z is the plunger number.

[0054] When the three pumps are combined, for the first pump, the flow function is:

[0055]

[0056] In the formula, is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com