Novel high-strength wear-resisting mooring rope

A cable and high-strength technology, applied in the field of new high-strength wear-resistant cables, can solve problems such as insufficient connection, large elongation, and potential safety hazards, and achieve the effect of safe use, low elongation, and strong wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

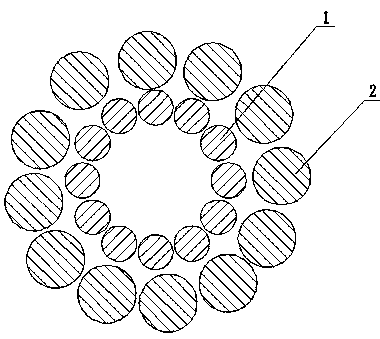

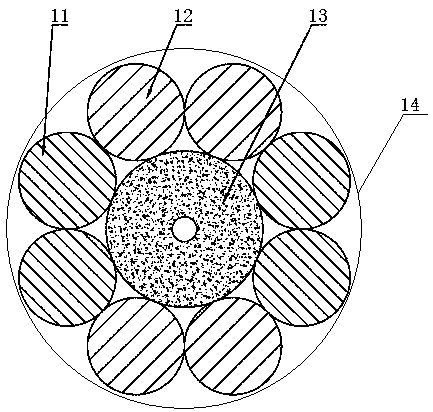

[0012] Such as figure 1 and figure 2 A new type of high-strength wear-resistant cable shown includes a twelve-strand cable body 1 arranged on the inner layer and twelve polyester strands 2 arranged on the outer layer. The cable body 1 includes a central column 13, and the inner layer and the outer layer Layer 14, the central column 13 adopts a rubber column, and the inner layer is formed by interlacing braiding of multiple strands of load-bearing ropes. The tensile rope is made of polyester, nylon and fibrous ultra-high molecular weight polyethylene mixed and twisted, the outer layer 14 is made of double-layer braided outer rope, the outer rope is twisted by polyester, the outer A filter belt is also provided between the layer 14 and the inner layer, and the filter belt is wound on the outer peripheral side wall of the inner layer.

[0013] A fine hole is opened through the center of the rubber column, and the diameter of the fine hole is 0.5-1 mm.

[0014] The inner layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com