Multi-chamber water seal tank for coal gas pipeline

A technology for gas pipelines and water sealing grooves, which is used in furnace safety devices, petroleum industry, coke ovens, etc., can solve the problems of increased cost, complicated design, inconvenient operation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

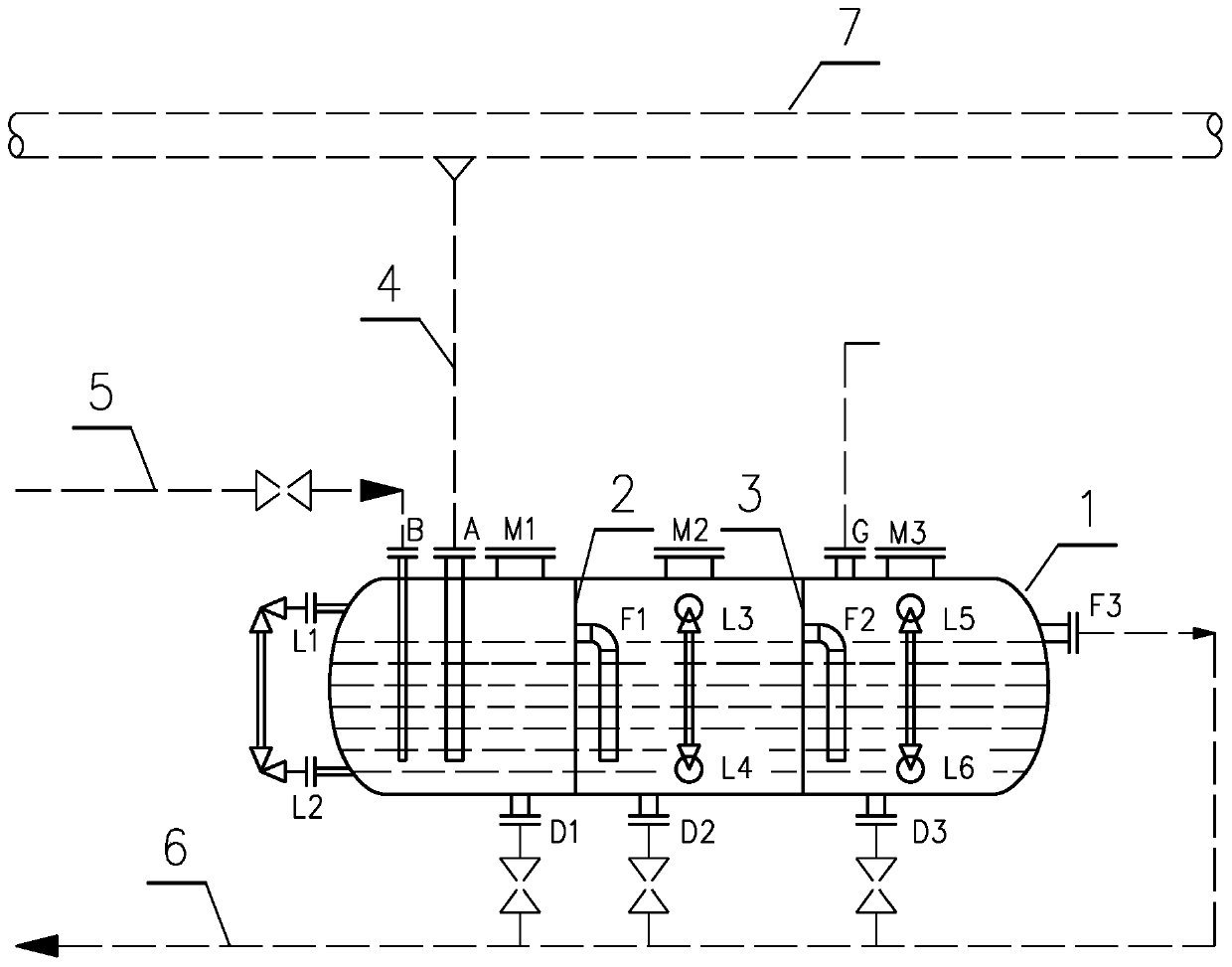

[0017] like figure 1 As shown, a multi-chamber water seal tank for gas pipelines according to the present invention includes a water seal tank 1; the internal space of the water seal tank 1 is divided into a plurality of independent tank chambers by partitions 2 and 3, including a An inlet tank, an outlet tank and at least one intermediate tank; the top of the inlet tank is provided with an industrial water inlet B and a gas condensate inlet A, and the top of the outlet tank is provided with a discharge port G; each partition 2 / 3 The upper part and the upper side of the outlet tank chamber are respectively equipped with full flow ports F1 / F2 / F3; the bottom of the inlet tank chamber, the middle tank chamber and the outlet tank chamber are respectively provided with vent ports D1 / D2 / D3; the inlet tank chamber, the middle tank chamber Both the cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com