A solar module junction box positioning and assembling system and its positioning and assembling method

A technology of solar modules and assembly methods, applied in welding equipment, welding equipment, auxiliary devices, etc., to achieve the effects of scratch prevention, high positioning accuracy, and easy adjustment and modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

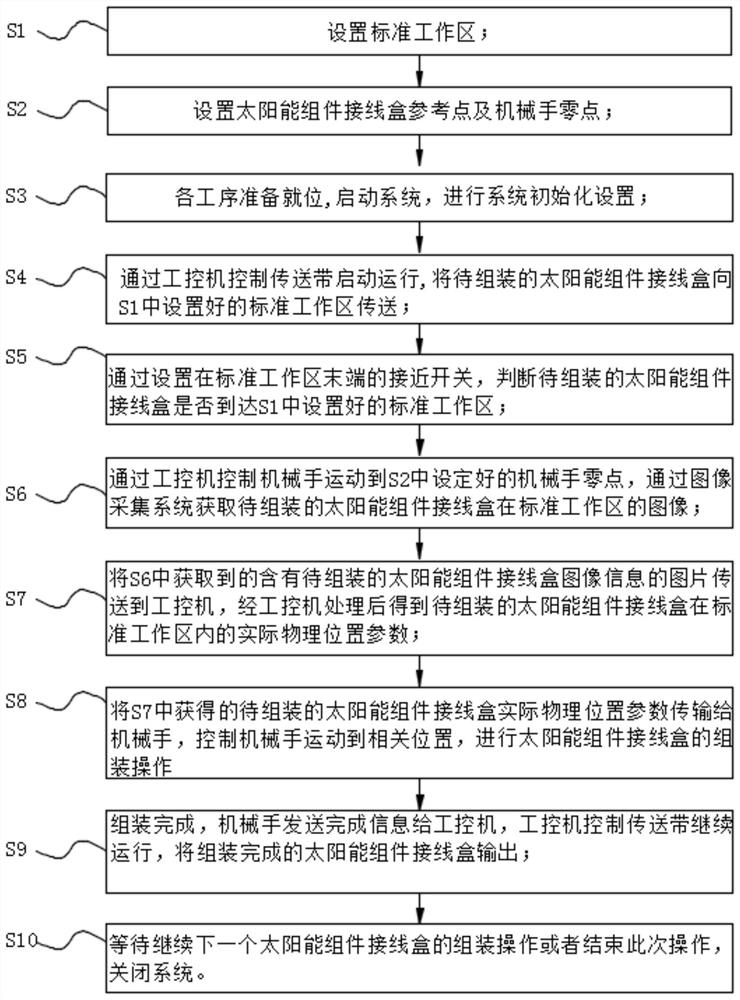

[0053] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following will further explain how the present invention is implemented in conjunction with the accompanying drawings and specific implementation methods.

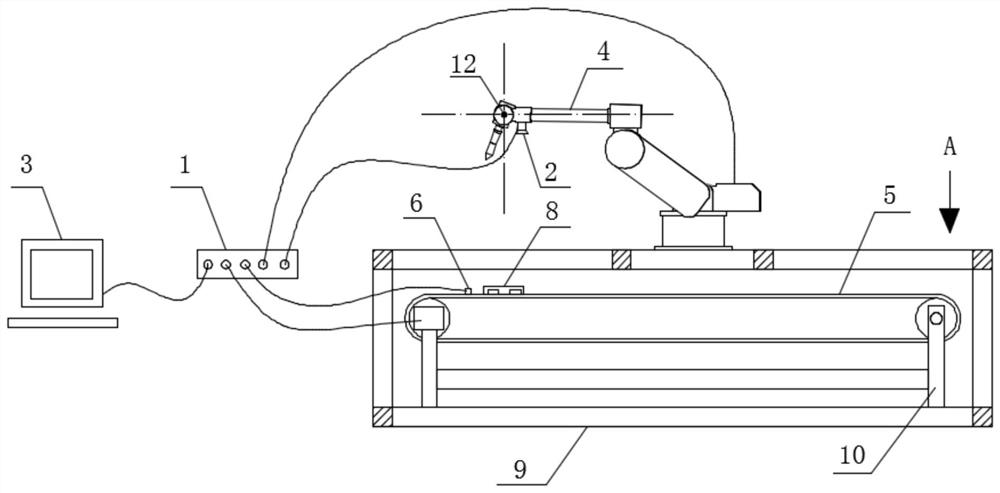

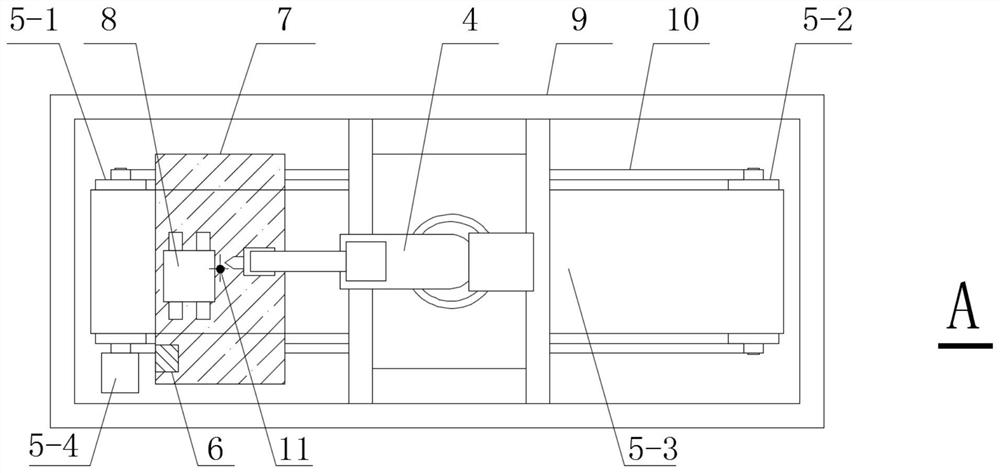

[0054] Such asfigure 1 and figure 2 As shown, the solar module junction box positioning assembly system provided by the present invention includes a gigabit network hub 1, an image collector 2, an industrial computer 3, a manipulator 4, a conveyor belt 5 and a proximity switch 6; wherein:

[0055] The gigabit network hub 1 is respectively connected with the image collector 2, the industrial computer 3, the manipulator 4, the conveyor belt 5 and the proximity switch 6 by wire for data transmission;

[0056] The image collector 2 is arranged on the manipulator 4, and is used to take images of the solar module junction box 8 to be assembled at the standard work area 7, and pass the image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com