Method for completely mitering and stacking dry type transformer core

A technology of dry-type transformers and oblique joints, which is applied in the field of transformer manufacturing, can solve the problems of difficult stacking and complicated stacking procedures of iron cores, and achieve the effect of improving the quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

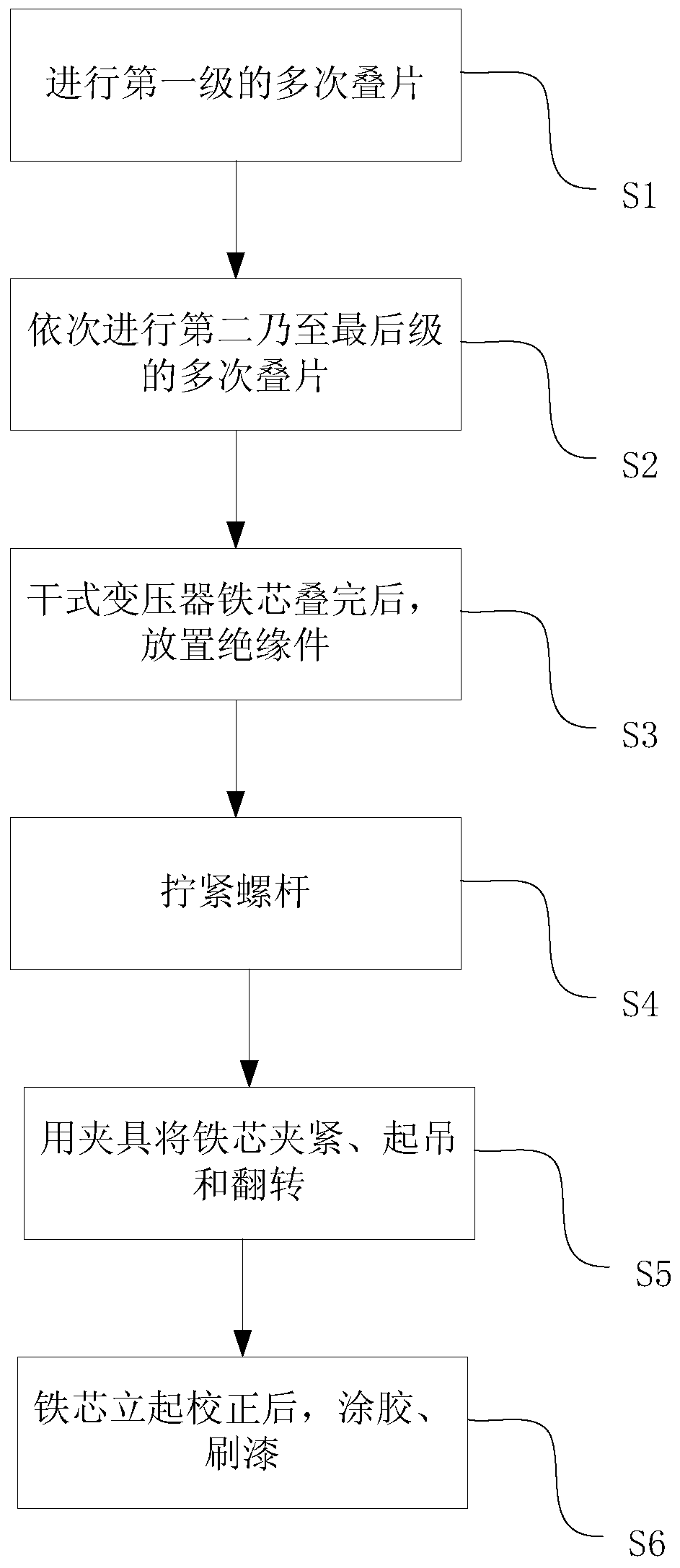

[0020] see figure 1 , the dry-type transformer iron core fully oblique seam stacking method of the present invention comprises the following steps:

[0021] Step S1, carry out multiple laminations of the first level: two pieces and one stack, after the first lamination, use a level to measure its flatness, if it is not flat, adjust it until it is level, and then use a tape measure to measure the iron core The diagonals of the two windows should make the lengths of the four diagonals exactly the same, if they are inconsistent, adjust them immediately. After the first level is stacked, place the knocking plate on the edge of the iron chip and gently tap the knocking plate along the edge of the iron chip with a hammer to keep the edge neat, then use a level to measure its flatness, and measure it with a tape measure If the diagonals of the two windows of the iron core do not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com