Rough crack changing opening degree for visualization experiment and manufacture method thereof

A fissure and roughness technology, applied in suspension and porous material analysis, permeability/surface area analysis, measuring devices, etc., can solve the uneven distribution of the upper and lower plate openings of rough fissures, damage, increase the same distance, etc. problem, to achieve the effect of accurate and reliable average opening value, high precision and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

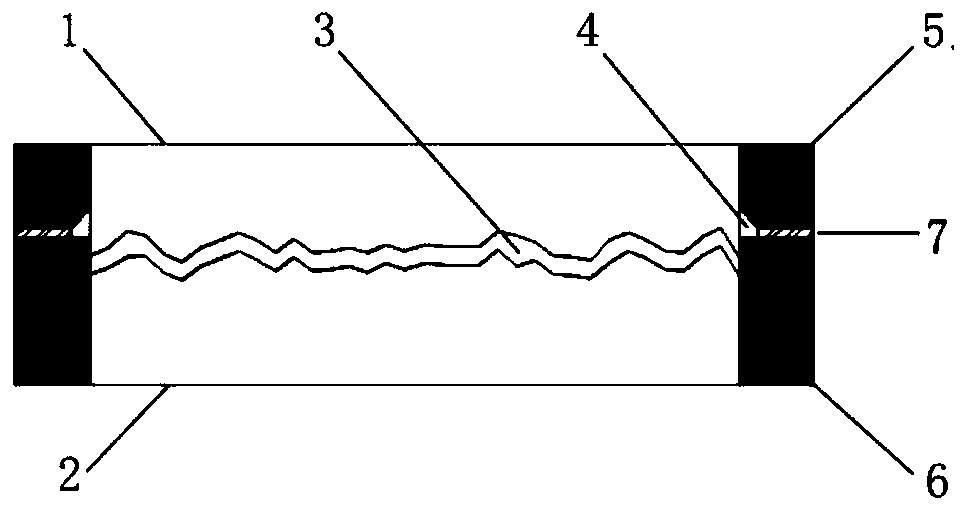

[0027] As shown in the figure, the variable-opening rough crack used in the visualization experiment of the present invention includes a rough crack upper wall 1, a rough crack lower wall 2, a crack space 3, a reserved water-stop cavity 4, and an upper edge baffle 5, Lower edge baffle 6, rigid spacer 7. The crack space 3 is formed when the upper wall 1 of the rough crack and the lower wall 2 of the rough crack are closed, and provides smooth and stable boundary conditions for the crack space. The interior of the space allows the passage of the experimental fluid, and the upper edge baffle 5 and the lower edge baffle 6 are firmly connected On the upper wall 1 of the rough crack and the lower wall 2 of the rough crack, the average opening of the crack spac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com