Blowoff valve and liquid chromatograph

An evacuation valve and valve body technology, applied in the field of liquid chromatography, can solve the problems of cumbersome operation of the evacuation valve, damage to the system seal, increase in system pressure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

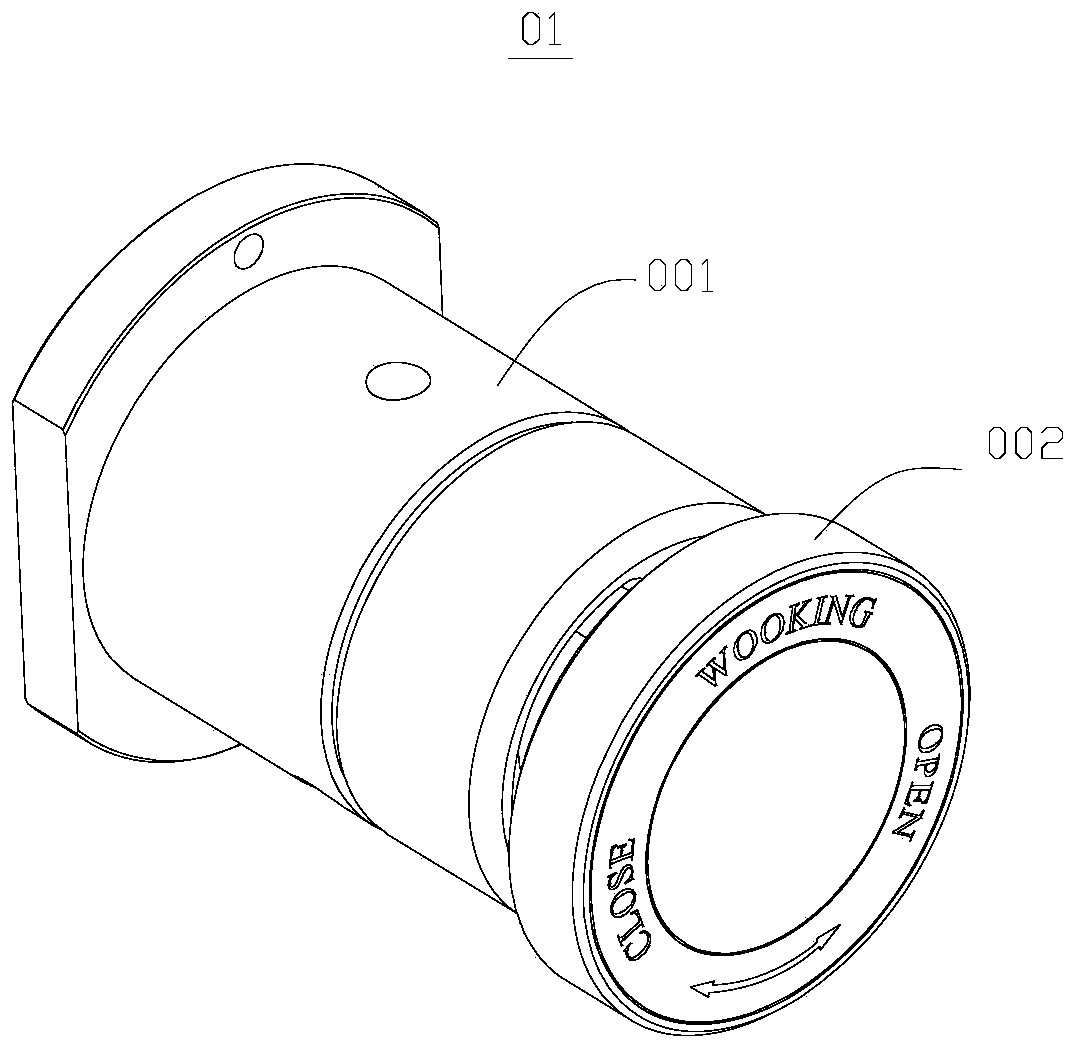

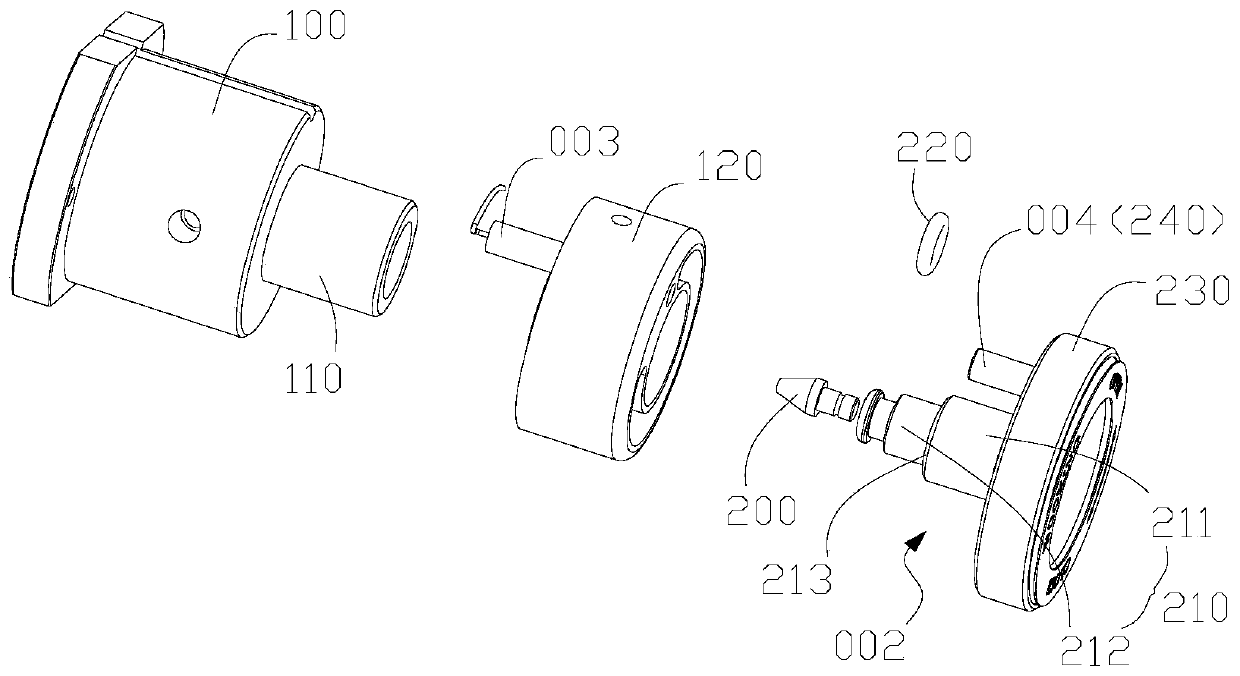

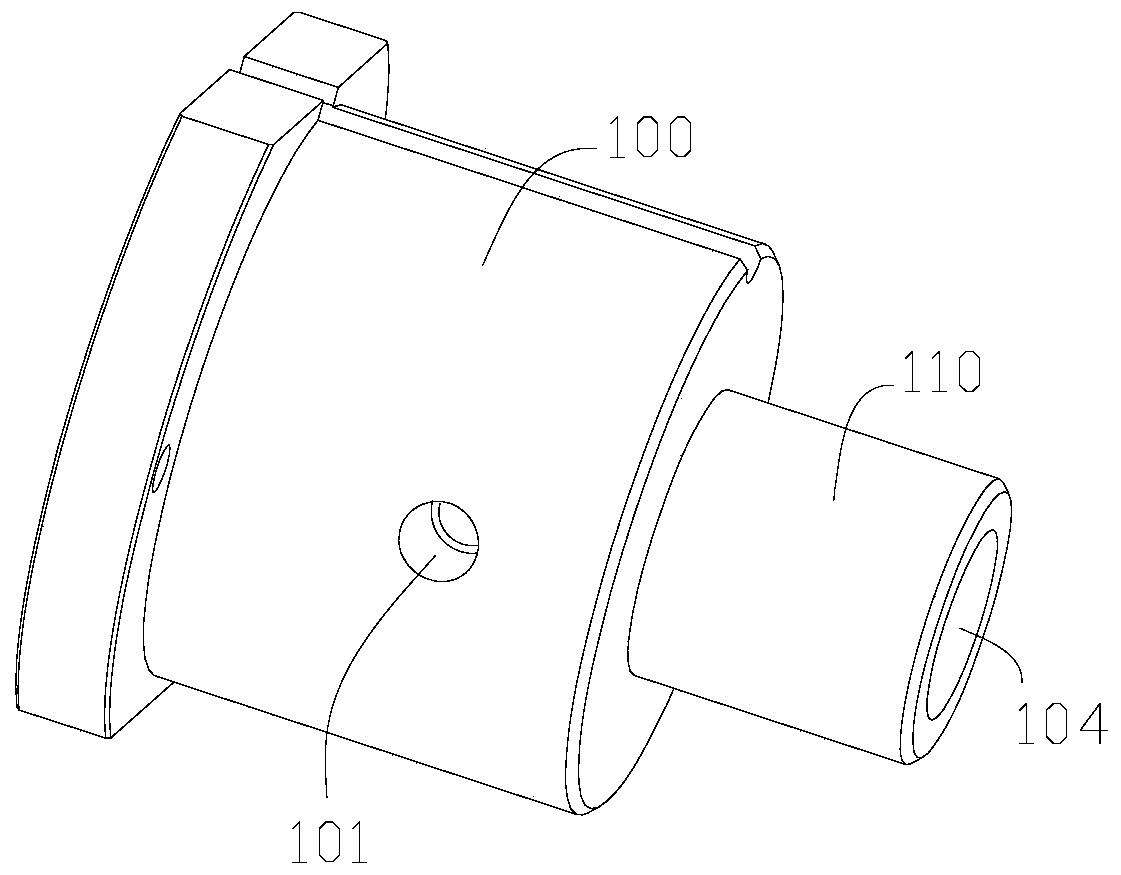

[0045] see figure 1 and figure 2 , this embodiment provides an emptying valve 01 for use with a transfer pump. The emptying valve 01 includes a valve body 001, a valve core 002 and a detection component 003. The valve core 002 is installed on the valve body 001 and can be relatively Move on the valve body 001 to adjust the working state of the valve body 001; the detection component 003 is installed on the valve body 001 or the valve core 002, and the detection component 003 is used to detect the working position of the valve core 002 relative to the valve body 001; the detection component 003 It is used for communication connection with the controller, the controller is used for communication connection with the delivery pump, and the controller adjusts the working state of the delivery pump according to the working position.

[0046] The emptying valve 01 provided by the present invention changes the working state of the valve body 001 by adjusting the position of the valv...

Embodiment 2

[0068] This embodiment provides a liquid chromatograph, including a delivery pump, a controller, and the emptying valve 01 mentioned in the above-mentioned embodiment 1. The outlet 1022 of the delivery pump communicates with the inlet 1012 of the valve body 001; the detection component 003 and the control The controller is connected in communication with the delivery pump, and the controller adjusts the working state of the delivery pump according to the working position of the spool 002. When there are air bubbles in the mobile phase, turn the spool 002 to move the spool 002 to the position of opening the exhaust port 1032. The controller detects that the spool 002 is at this position and controls the delivery pump to be in a state of high flow rate, and the air bubbles are discharged from the exhaust port. Hole 1032 vents.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com