Double-layer solid control system

A solid control system, double-layer technology, applied in wellbore/well components, earthwork drilling, flushing wellbore, etc., can solve the problems of long track length and large drilling rig area, and achieve short track length and land occupation. area reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

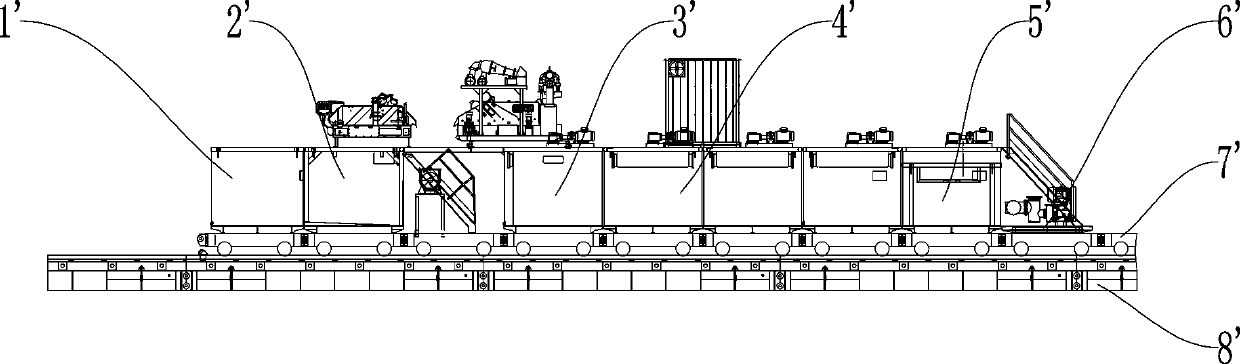

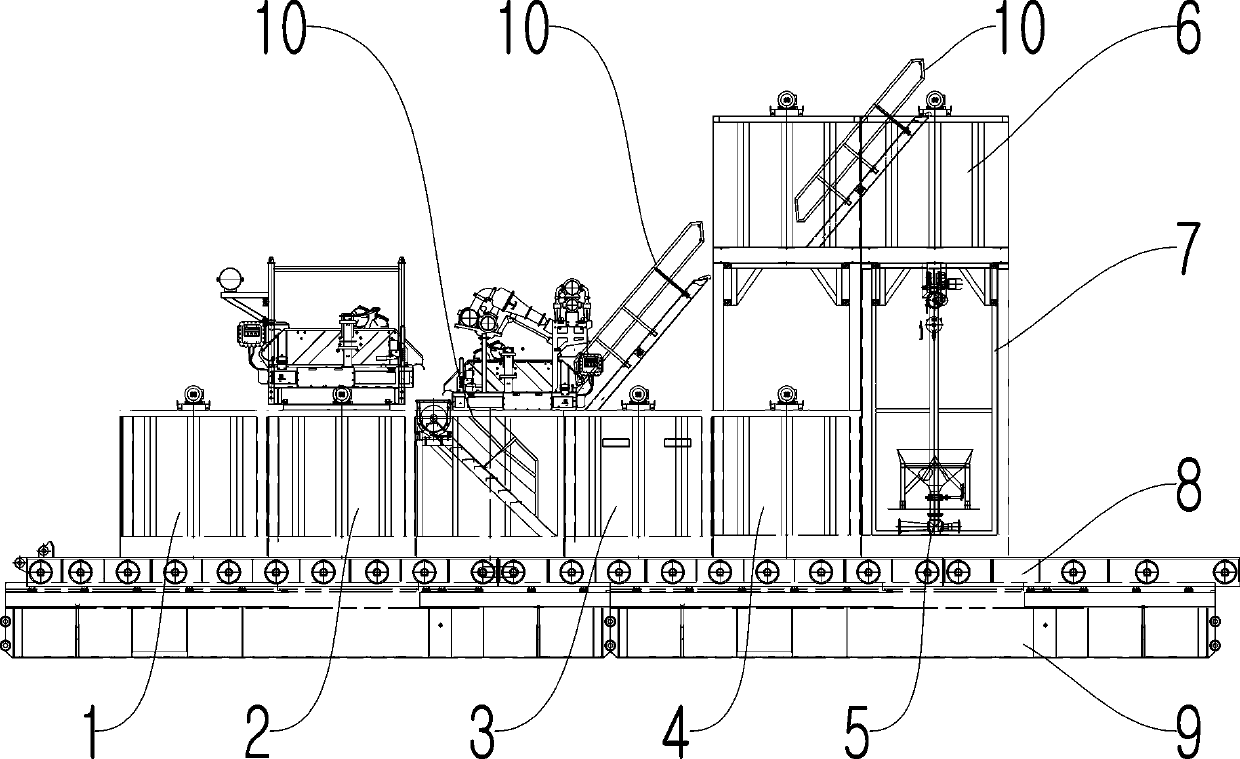

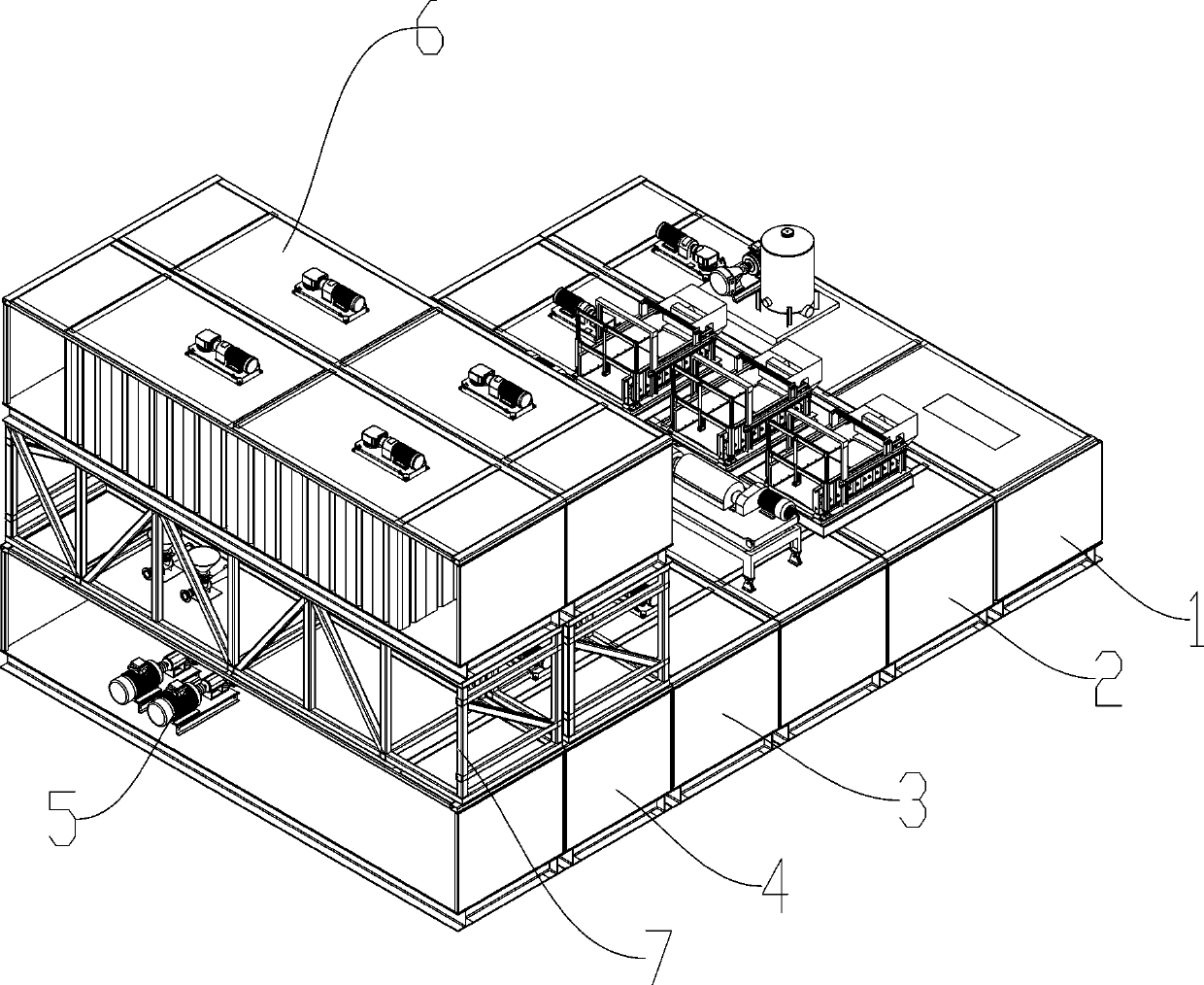

[0021] Such as Figure 2-3 As shown, the double-layer solid control system includes a track 9 fixedly connected to the foundation, a skid 8 movably connected to the track 9, a replenishment tank 1, a vibrating screen tank 2, a centrifuge tank 3, and a suction tank fixed on the skid 8 in sequence. Tank 4 and perfusion skid 5, intermediate bracket 7 fixedly connected to the top of suction tank 4 and perfusion skid 5, reserve tank 6 fixedly connected to the top of intermediate bracket 7, and intermediate bracket 7 divides the entire solids control system into upper and lower layers, and Including three ladders 10, one ladder 10 is connected to the top of the skid 7 and the first layer, one ladder 10 is connected to the top of the first layer and the top of the intermediate support 7, and one ladder 10 is connected to the top of the intermediate support 7 and the storage tank 6, the supply tank 1, the shaker tank 2, the centrifuge tank 3, the suction tank 4 and the perfusion skid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com