Installation method of daylighting roof

An installation method and lighting roof technology, which can be applied to roofs, roofs using flat/curved panels, and roofs, etc., can solve the problems of cumbersome installation process and long project progress, and achieve the effect of improving construction efficiency and saving scaffolding costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the drawings.

[0046] The first preferred embodiment:

[0047] A lighting roof installation method includes the following steps:

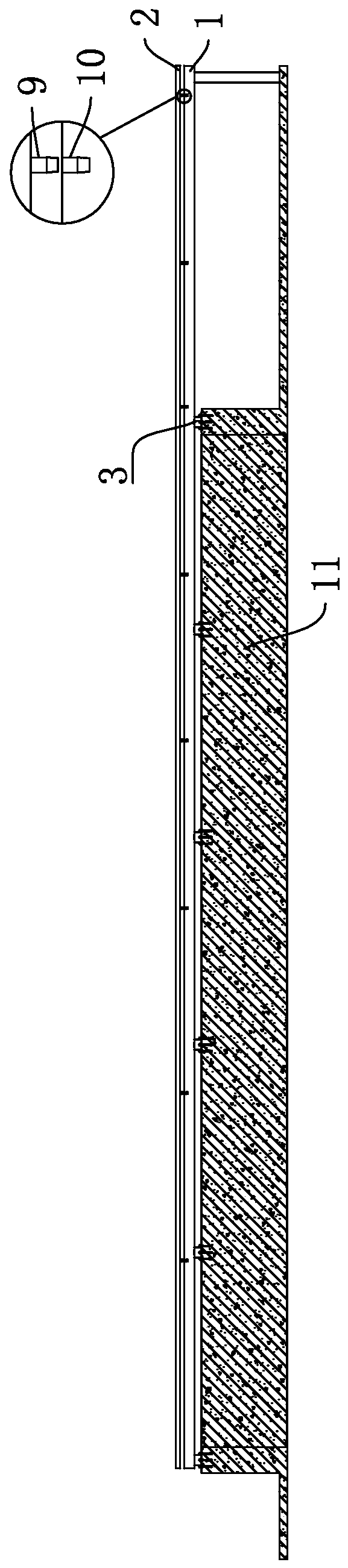

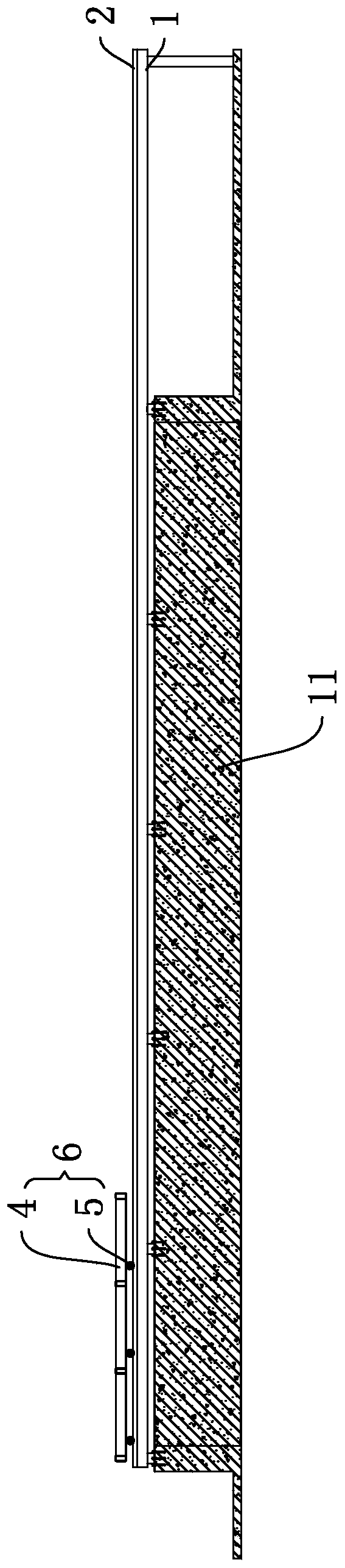

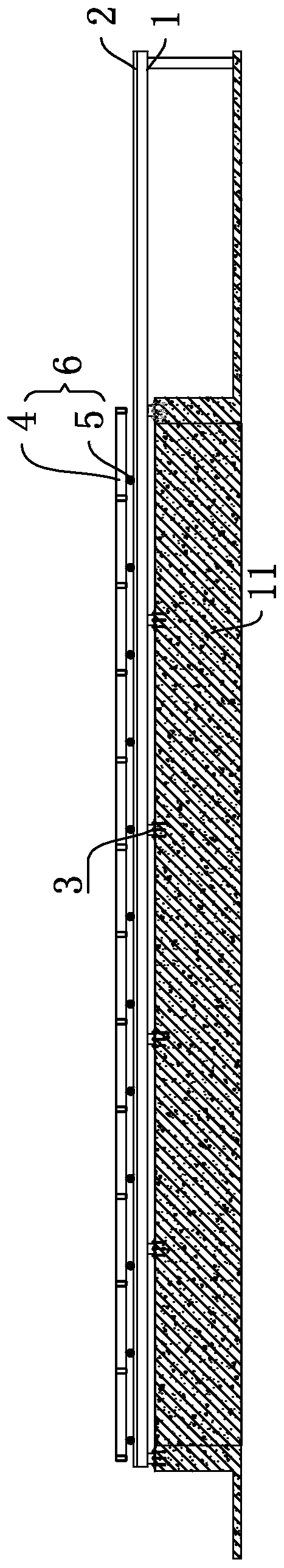

[0048] Step 1. Lay the main steel beam 1 along the long side of the parapet 11, and set up a track on the main steel beam 1. Specifically, the main arranging several flat supports 3 on the anchors of the parapet 11 3 are evenly arranged in the longitudinal direction of the parapet 11, the flat support 3 and the parapet 11 are anchored and connected, and the bottom of the main steel beam 1 is welded to the flat support 3.

[0049] To ensure the parallelism of the guide rail 2, a guide installation step is also included; the specific guide installation steps include:

[0050] Step 11: Draw auxiliary lines parallel to each other on the upper side of the two main steel beams 1 and the lower side of the two guide rails 2, and evenly mark a number of overlapping marking po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com