Belt conveyor bracket

A technology of belt conveyors and triangular brackets, applied in the direction of conveyors, conveyor objects, support frames, etc., can solve problems that affect the stable operation of the belt system, hidden dangers cannot be completely cured, and structural instability, etc., to achieve a simple structure , Uniform stress and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the following, only some exemplary embodiments are briefly described. As those skilled in the art would realize, the described embodiments may be modified in various different ways, all without departing from the spirit or scope of the present invention. Accordingly, the drawings and descriptions are to be regarded as illustrative in nature and not restrictive.

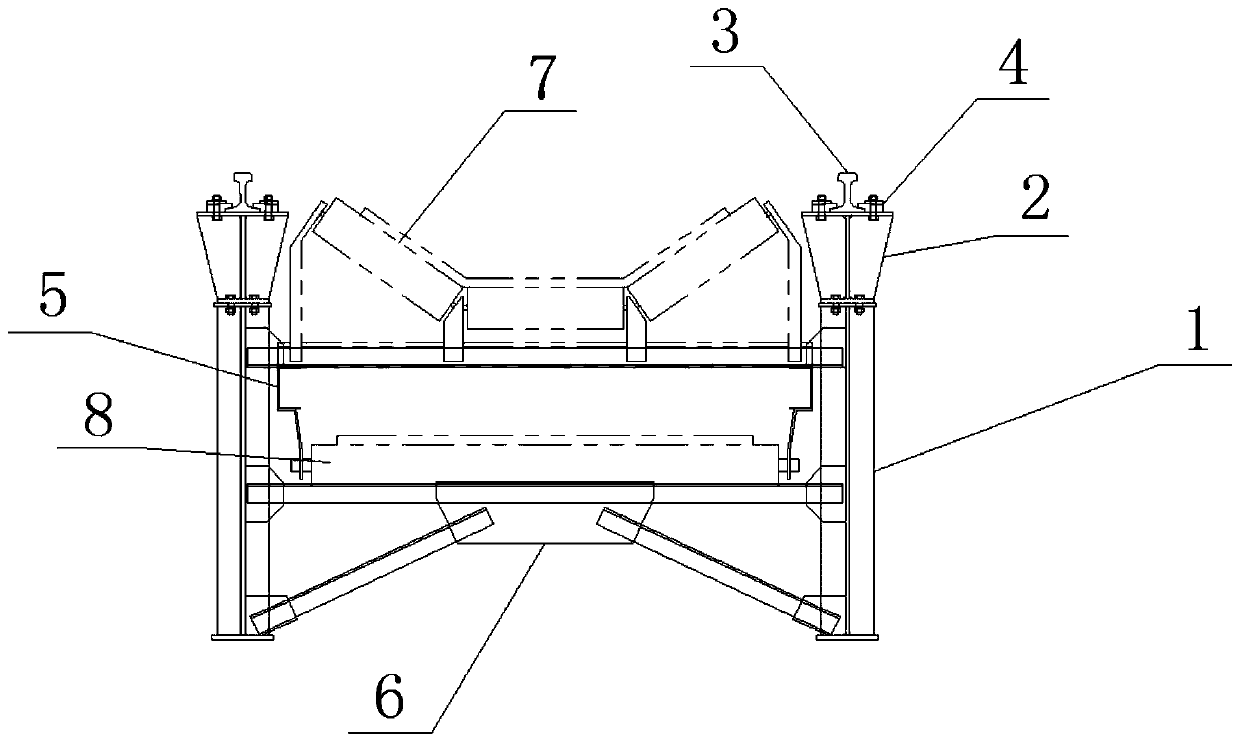

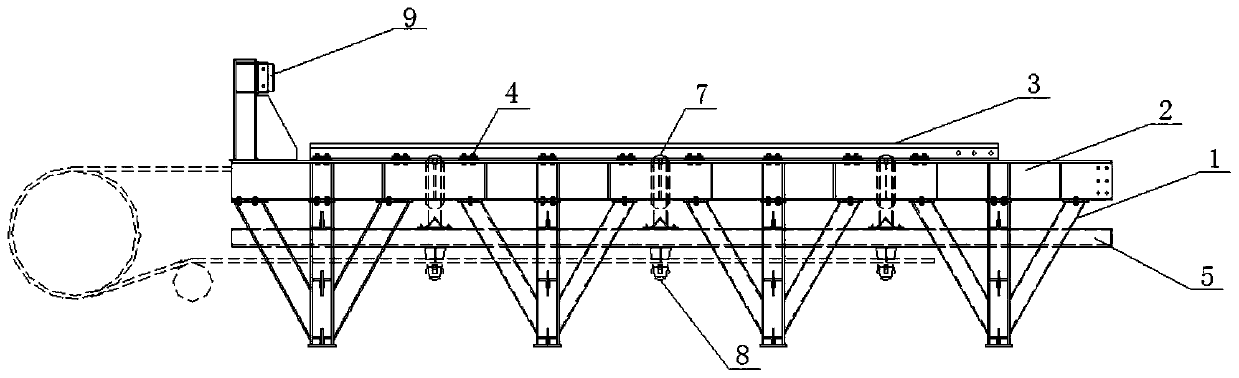

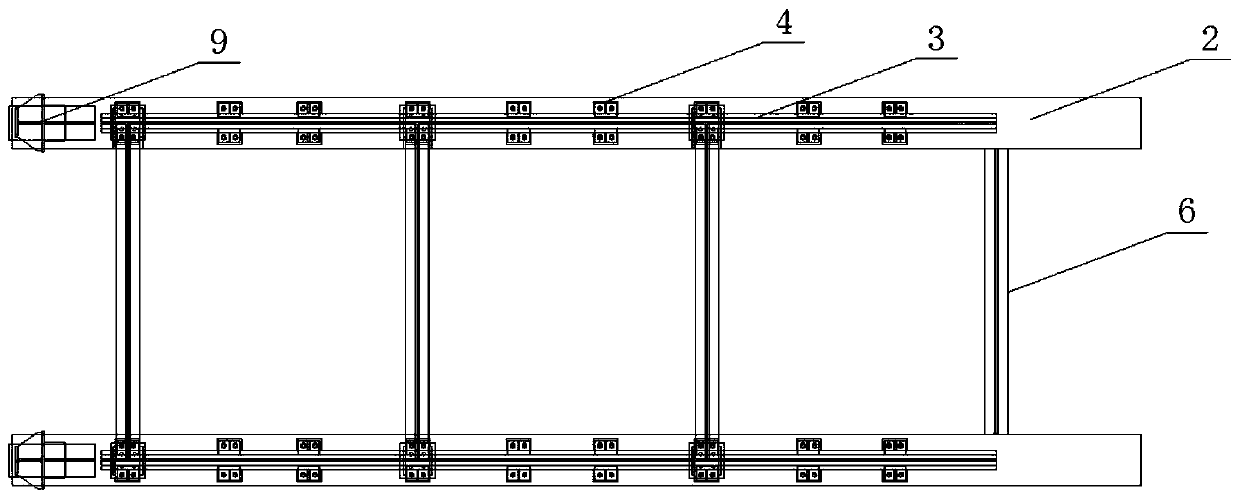

[0029] The following is attached Figure 1-5 The present invention will be described in detail.

[0030] Such as Figure 1-3 As shown, a schematic structural view of the belt conveyor bracket provided by the present invention is shown, and the belt conveyor bracket includes: a triangular bracket 1, a channel steel 5, an inclined leg 6, an upper idler roller assembly 7, a lower bracket Roller assembly 8, in which the base of the triangular bracket 1 can be directly located on the foundation embedded parts, the channel steel 5 is installed on the triangular bracket 1, the upper idler roller assembly 7 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com