Polypeptide concentrate steam drying machine

A technology of concentrated liquid and drying machine, which is applied in the direction of evaporation, evaporator accessories, and evaporators heated by serpentine tubes, etc. It can solve problems such as high temperature and loss of activity of small molecule peptides, and avoid clogging or too viscous , reduce the loss of activity, and avoid the effect of offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

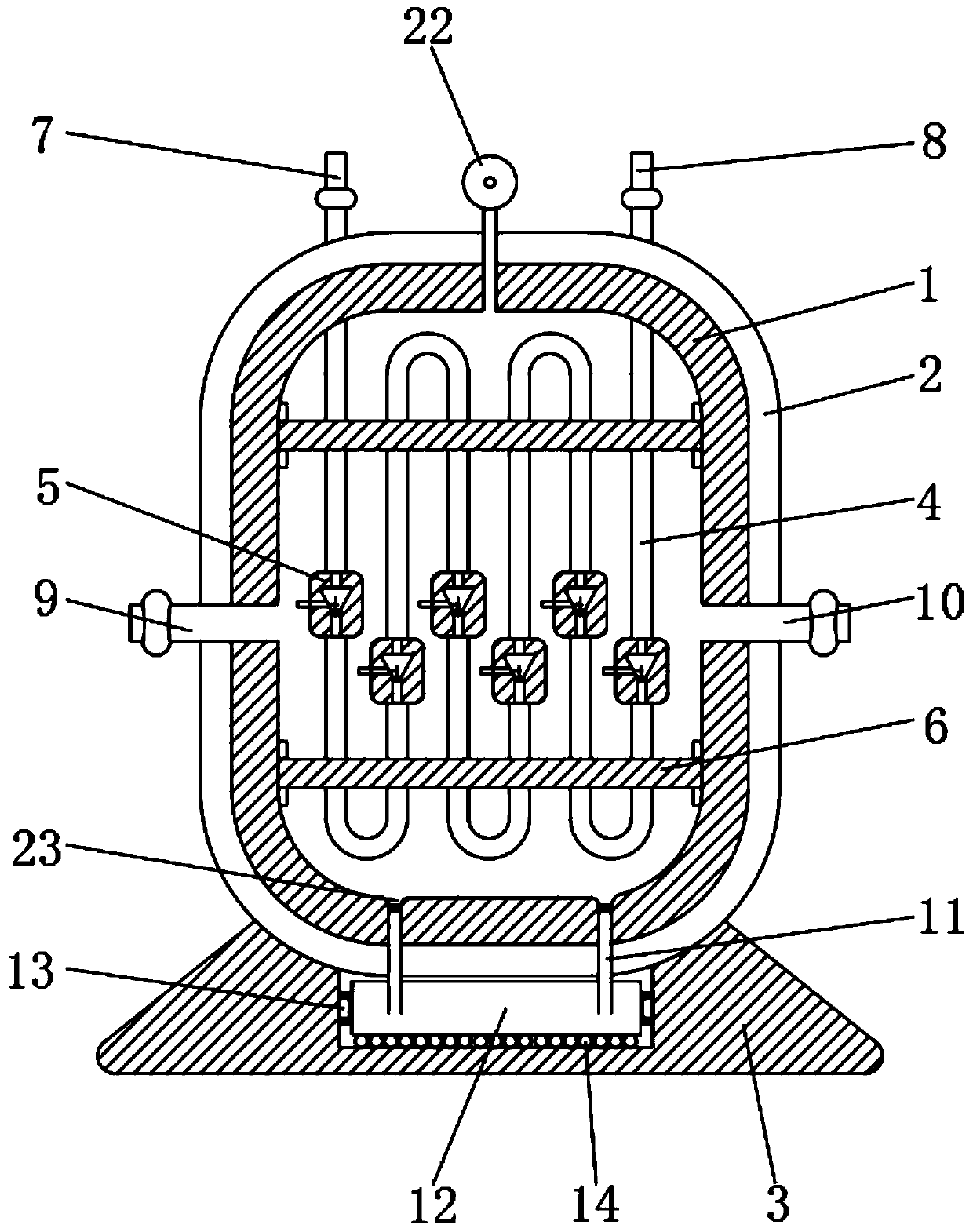

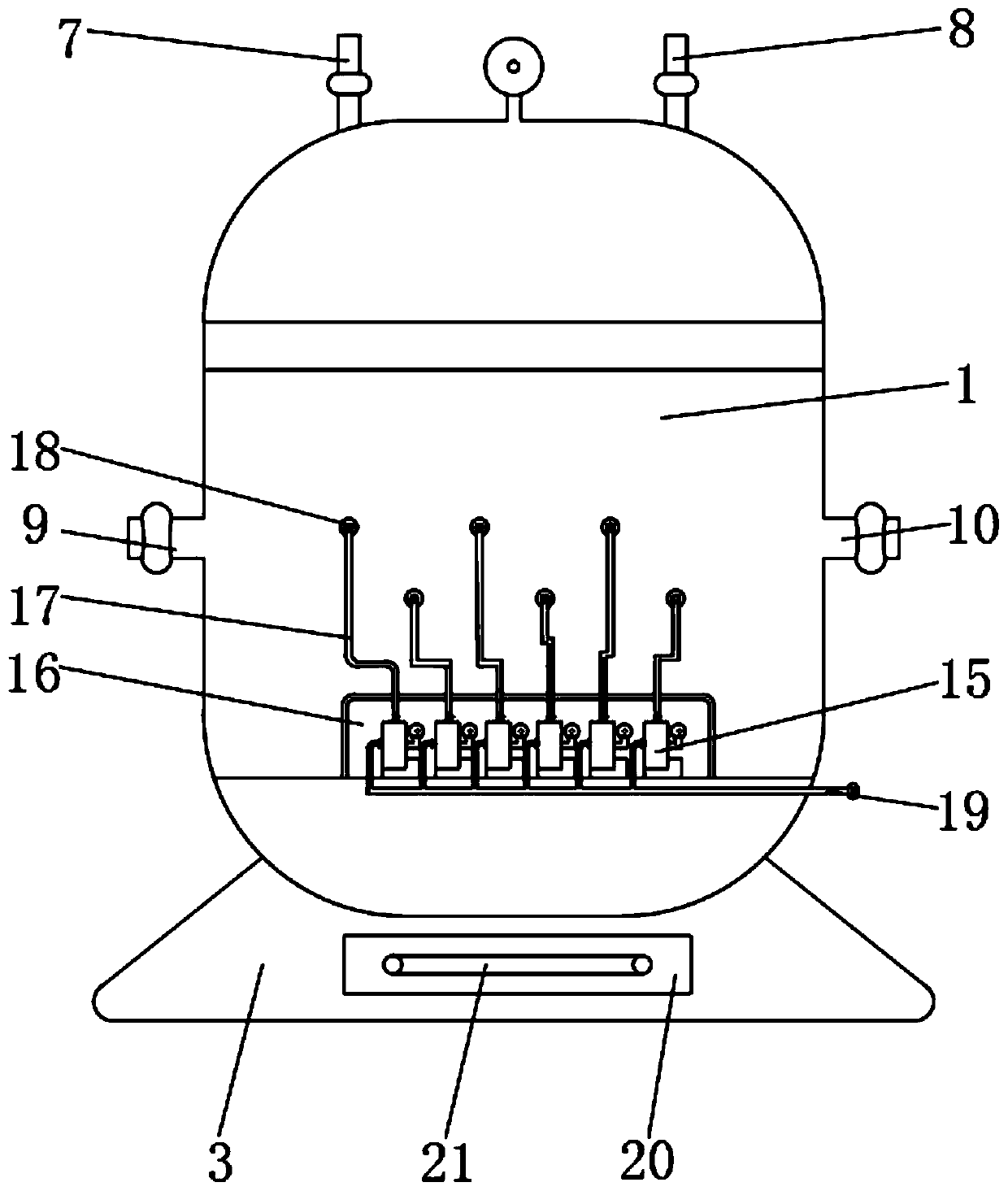

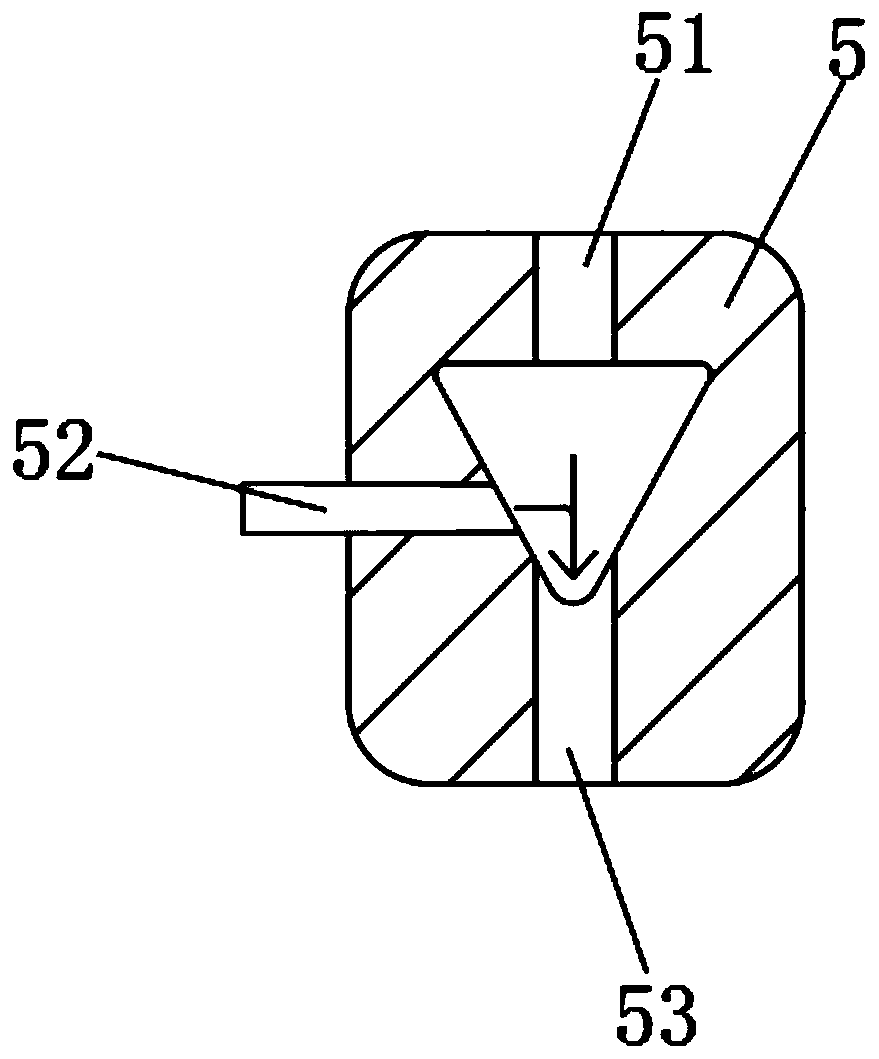

[0026] Example 1, refer to figure 1 , figure 2 and image 3As shown, a polypeptide concentrate steam dryer includes a kettle body 1 and a bottom frame 3, and a bottom frame 3 is installed at the bottom of the kettle body 1, and the bottom frame 3 is used to support and stabilize the kettle body 1, and the outer surface of the kettle body 1 is Covered with a thermal insulation layer 2, the thermal insulation layer 2 is used to prevent the loss of heat energy of the kettle body 1, causing waste, and a drying tube 4 is installed in the kettle body 1, and the drying tube 4 is used to circulate the polypeptide concentrate, and the drying tube 4 is " The un" type is arranged side by side, and the drying tube 4 is continuously arranged in the kettle body 1, so that the contact area of the drying tube 4 in the kettle body 1 is increased, so as to achieve the drying treatment of the polypeptide concentrate circulating inside, The upper part and the lower part of the drying tube 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com