A kind of transparent superhydrophobic coating and its preparation method and application

A super-hydrophobic coating and transparent technology, applied in coatings and other directions, can solve problems such as poor light transmission, and achieve the effects of improving safety, water repellency, and light transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

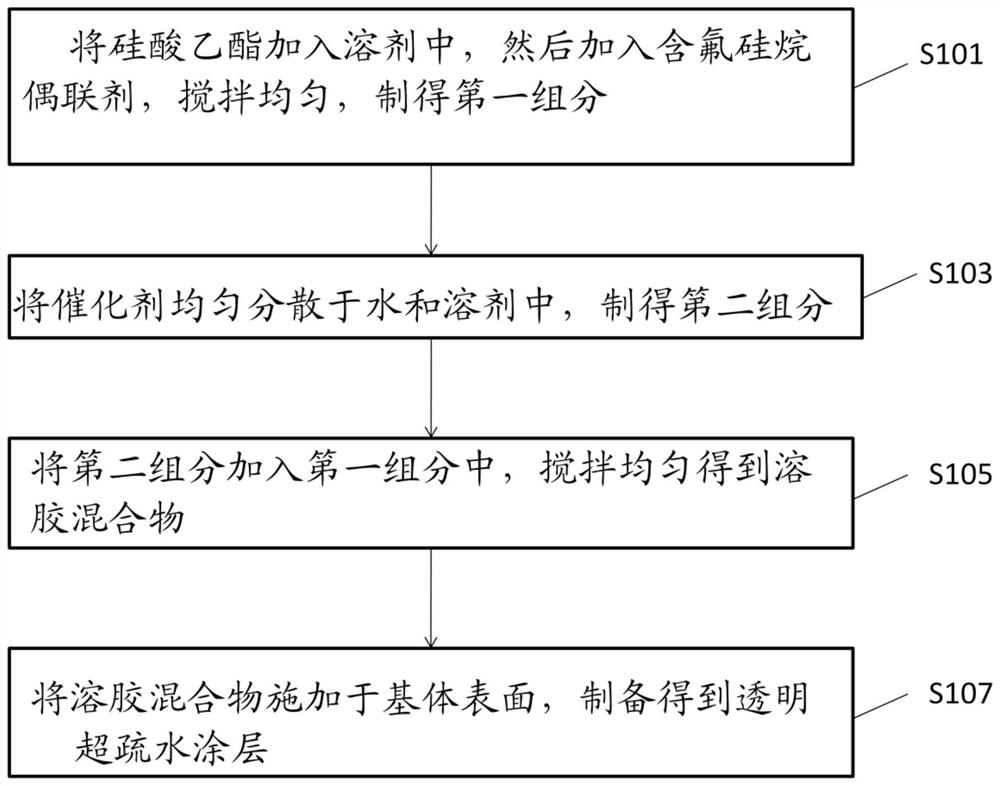

[0026] The preparation method of transparent superhydrophobic coating provided by the invention may further comprise the steps:

[0027] Such as figure 1 As shown in step S101, ethyl silicate is added into the solvent, then a fluorine-containing silane coupling agent is added, and stirred evenly to obtain the first component, wherein the stirring time is 0.5-1.5 hours. In this step, the fluorine-containing silane coupling agent is selected from one or a combination of tridecafluorooctyltriethoxysilane and heptadecafluorodecyltriethoxysilane; in this step, the solvent A combination of one or more selected from ethyl acetate, ethanol, propanol, n-butanol, and ethylene glycol.

[0028] Such as figure 1 As shown in step S103, the catalyst is uniformly dispersed in water and a solvent to prepare the second component. Wherein, catalyst is selected from acid catalyst or basic catalyst, for example, acid catalyst is selected from the combination of one or more in oxalic acid, phosp...

Embodiment 1

[0034] Add 1 g of ethyl silicate to 300 g of ethanol solvent, then add 1 g of tridecafluorooctyltriethoxysilane, and stir mechanically for 1 h to obtain the first component; then add the second component to the first component dropwise, The second component is a mixture of 12g of ammonia water, 25g of water and 100g of ethanol. Stirring is continued for 2 hours to obtain a transparent sol, which is then applied to the glass surface by scraping.

Embodiment 2

[0036] Add 1g of ethyl silicate to 300g of ethanol solvent, then add 1g of tridecafluorooctyltriethoxysilane, stir mechanically for 1h to obtain the first component, then add the second component to the first component dropwise, The second component is a mixture of 12g of phosphoric acid, 25g of water and 100g of ethanol. Stirring is continued for 12 hours to obtain a transparent sol, which is then applied to the glass surface by spraying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com