Polymeric amino acid gypsum retarder

A technology for polymerizing amino acid and gypsum retarder, which is applied in the field of polymerized amino acid gypsum retarder, and can solve problems such as the greater impact on the strength of gypsum materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

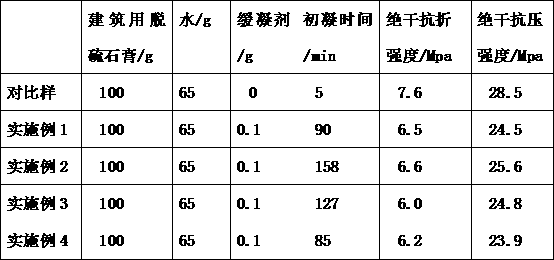

Image

Examples

Embodiment 1

[0018] Weigh 30kg of glutamic acid, 30kg of lysine, and 40kg of aspartic acid, react at 190°C for 4h, cool to 120°C, add 100kg of 10% potassium hydroxide aqueous solution to the system and continue to react for 1h, and the material is dried and pulverized Afterwards, the product 1 was obtained, and the average molecular weight was determined to be 2000.

Embodiment 2

[0020] Weigh 20kg glutamic acid, 20kg lysine, 60kg aspartic acid, react at 260°C for 40min, cool to 60°C, add 10% sodium hydroxide aqueous solution to the system and continue to react for 2h, after drying The product 2 was obtained after pulverization, and the measured average molecular weight was 6000.

Embodiment 3

[0022] Weigh 10kg of glutamic acid, 70kg of lysine, and 20kg of aspartic acid, react at 240°C for 30min, add 120kg of 10% sodium hydroxide solution after cooling to 120°C, and continue to react for 2h, and obtain product 3 after drying and crushing. The average molecular weight was measured to be 3000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com